How to fit Whitbread bucket seats to your Discovery in 10 easy steps

First, take out your old seats, which are actually surprisingly lightweight

Then, get your new seats upturned and ready for measuring

Then, produce a particularly shonky cardboard template out of an old air filter box, marking out the bolt hole patterns for both seat and rail, I picked up the front inner bolt as a common as it was the correct sort of position and gave a reference to work from

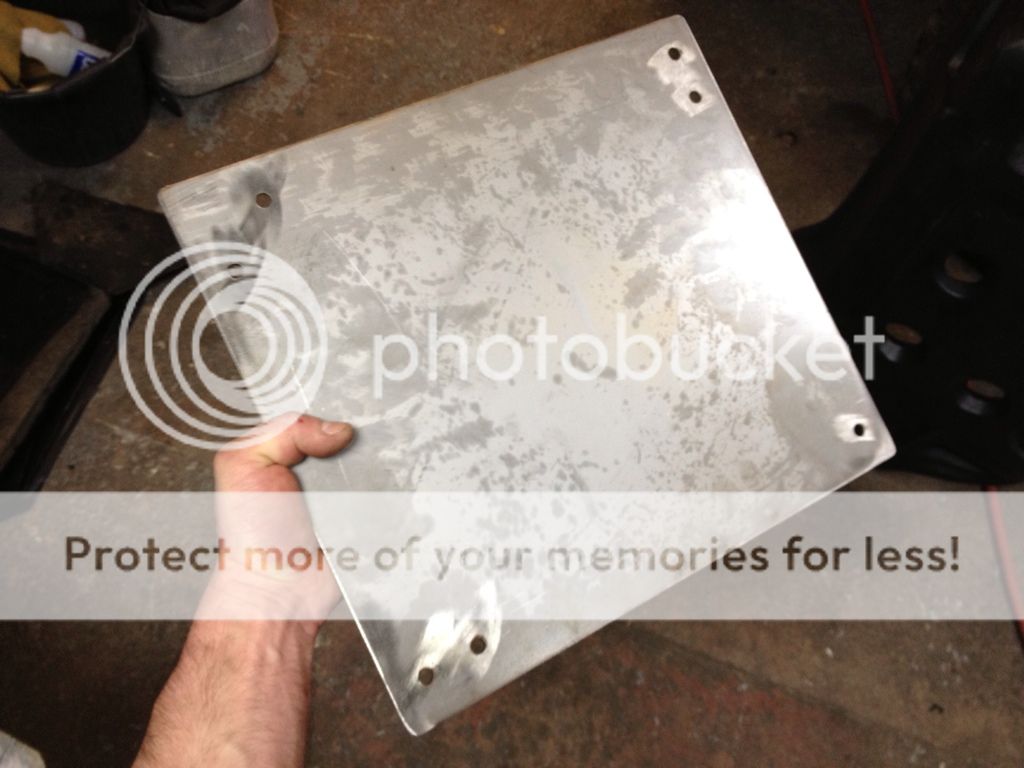

Then, take this shonky template to your nearest metal fabricator and ask them to turn it into two pieces of 3mm stainless steel. Apologise to them for the shonkiness of the template. NB both plates are identical you just use them in reverse.

Also ask them to make the bolt holes 8mm, not 6mm like me because you just guessed like me, otherwise like me you will have to go back tail between legs and ask them to drill them out to 8mm for you

Then test fit the plate to the seat, put a bolt in the common hole and check for alignment. You will have to file out the holes a bit in places because the template was shonky

When finished, bolt to the seat and then mark through on the seat where the rail holes are

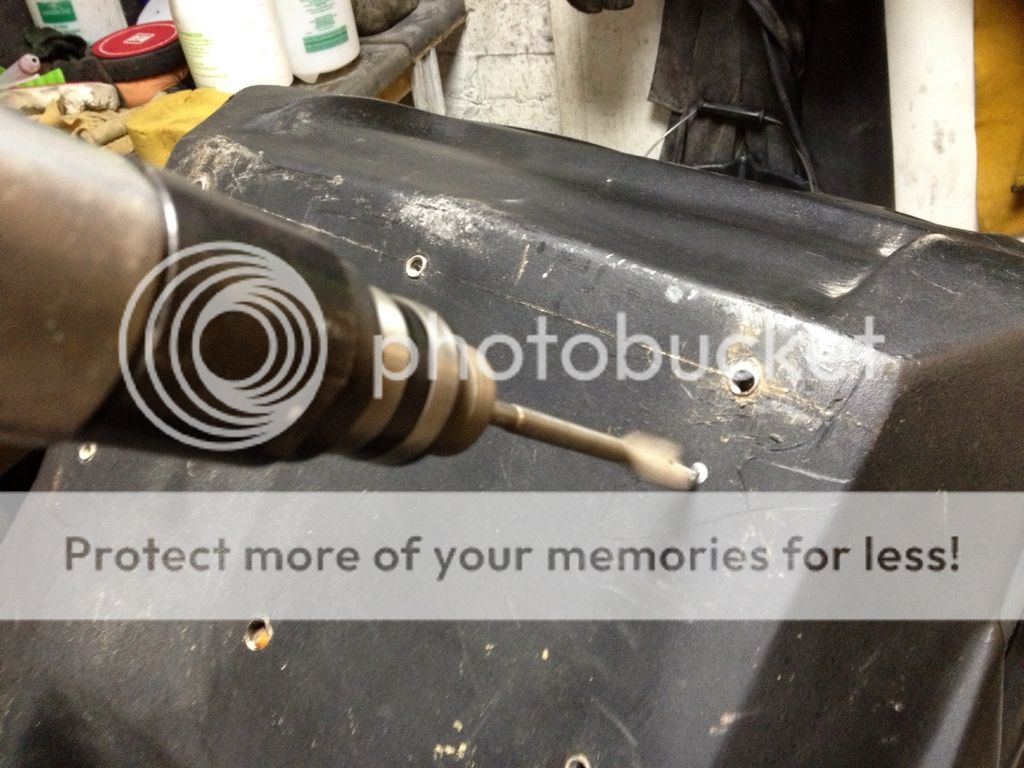

Because then you will have to remove the plate and recess the bottom of the seat to allow for the bolt heads where you are going to bolt the plate to the rail

Next up test fit the plate to the rails. Like me, your cardboard template will be shonky so more filing will be required to make it fit

Once sorted, bolt the plate down to the rails, use nylok nuts and check that access is clear for the bolts which thread into the seat from below.

Offer up the seat, start with the common bolt through the rail and plate, then find the others and bolt the seat(s) down.

Done