Glyn D

Active Member

- Posts

- 134

- Location

- North wales

Hi all, I posted a while back when I was about to buy my first Defender.

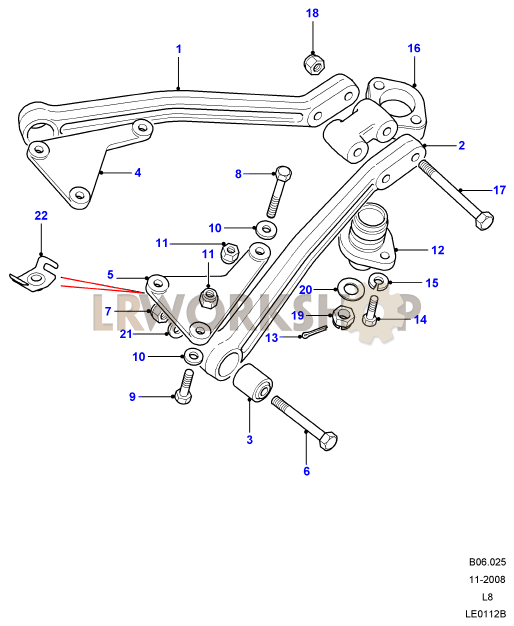

I went ahead and bought it, it's a 1996 300tdi Defender 90 and have tinkered with it almost every day since. Today's job is the rear A Frame ball joint but it's proving to be a bit difficult.

I've manage to free up most of the bolts with a big hammer. The problem I'm having now is that the ball joint thread is turning whilst I'm trying to undo the 30mm nut which secures it to the axle.

Any suggestions how to stop the ball joint from turning so that I can remove the nut?

I went ahead and bought it, it's a 1996 300tdi Defender 90 and have tinkered with it almost every day since. Today's job is the rear A Frame ball joint but it's proving to be a bit difficult.

I've manage to free up most of the bolts with a big hammer. The problem I'm having now is that the ball joint thread is turning whilst I'm trying to undo the 30mm nut which secures it to the axle.

Any suggestions how to stop the ball joint from turning so that I can remove the nut?