- Posts

- 7,768

- Location

- East Midlands

I've been busy with my suspension today. I even remembered to take some pictures. I have elderly Britpart shock absorbers and the car is starting to look a bit low in the water at the rear. So once it stopped raining I started unscrewing things.

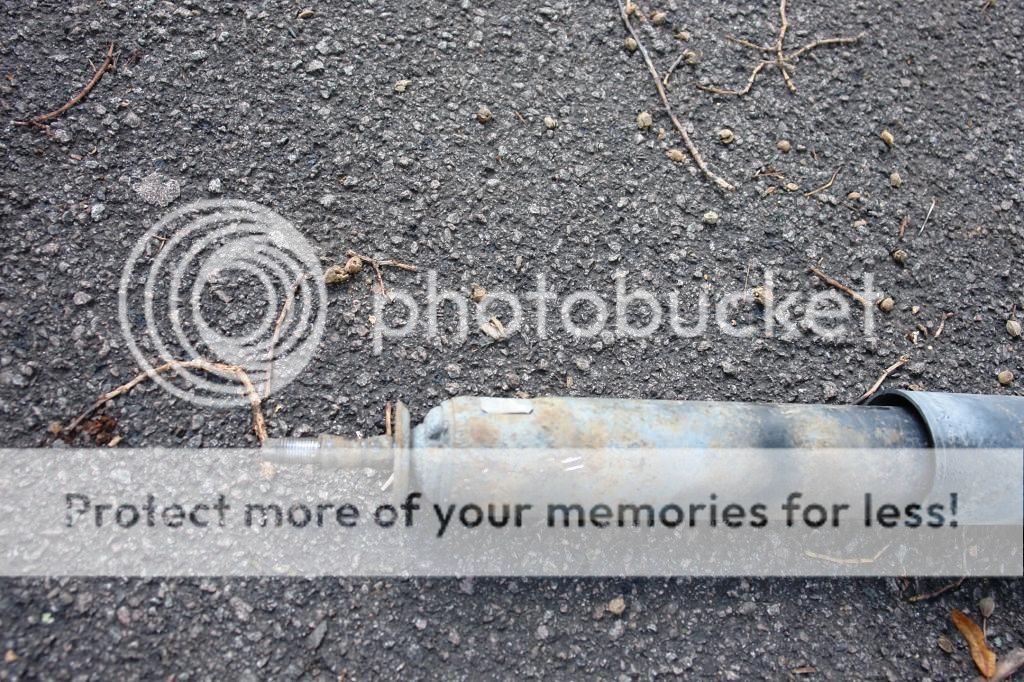

Here's one of the offending items complete with the Britpart logo of doom:

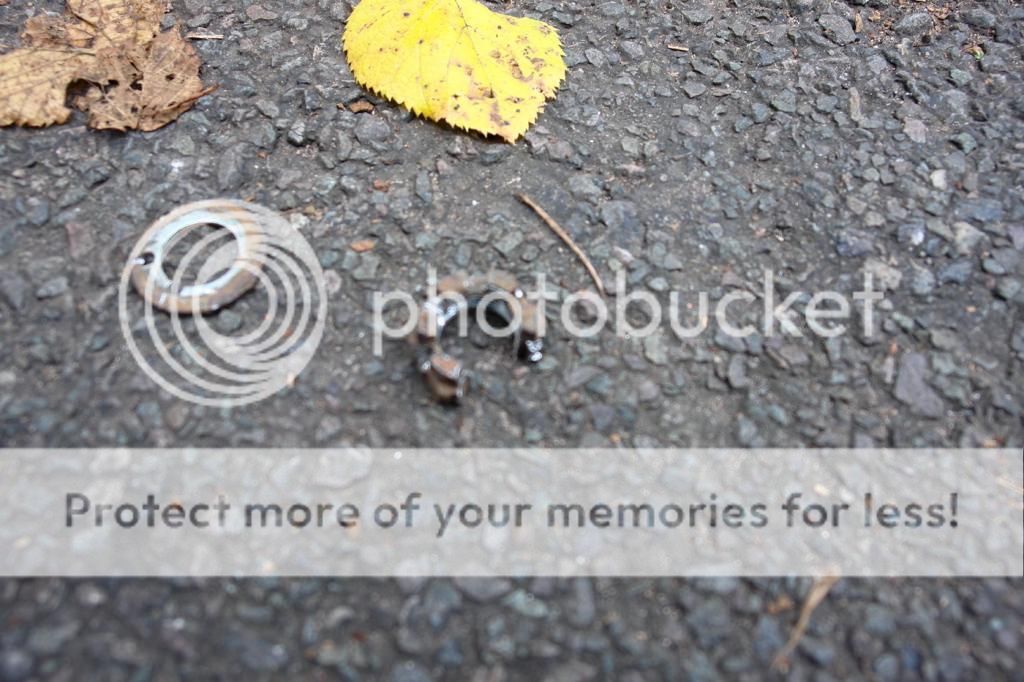

I'm putting new suspension bushes in too. Partly, this job was prompted by me finding some slack in the bushes which join the rear radius arms to the chassis. So here's a picture of everything off:

The nuts at the end of the radius/trailing arms were a bit of as struggle to undo. The poor old Milwaukee impact wrench rattled the rust off but didn't shift them. The 3/4" breaker bar and socket merely twisted the radius arm. I was wondering how to cut them off, but the nuts live in a recess in the bracket at the side of the chassis and are hard to get at with grinder or saw. Hmm. Fortunately, a freshly charged battery on the impact wrench did the trick, and easing the nuts back and forth half a turn eventually loosened them sufficiently to unscrew. Phew.

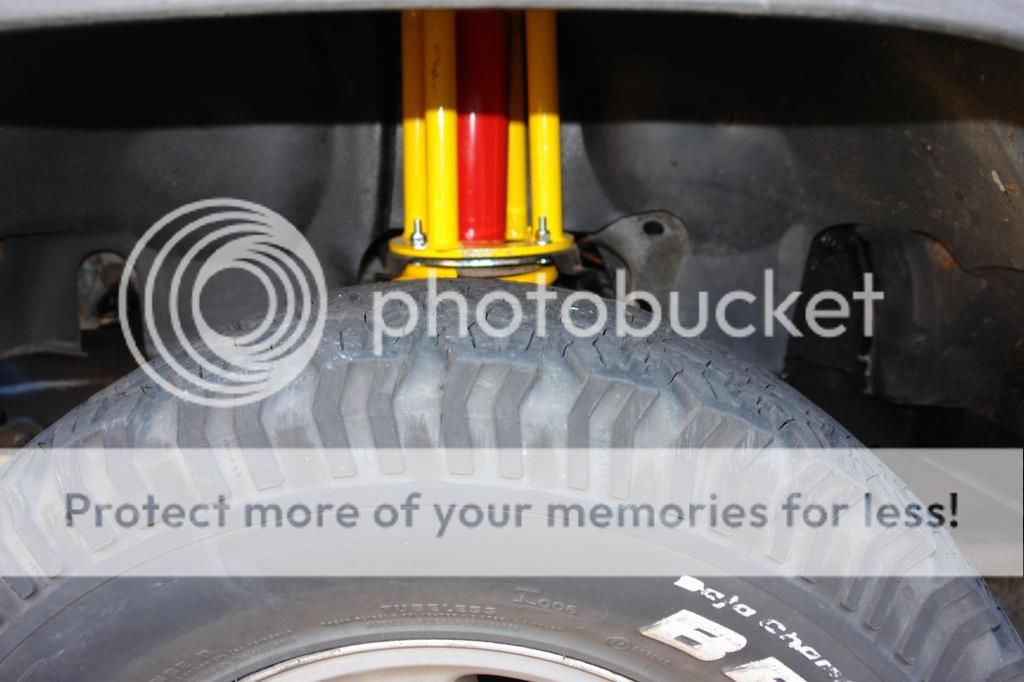

Reassembly was a lot quicker. Nice new springs and shocks in position:

I've got it some posh Koni dampers. You can see the new radius arm bush too. This might well re-ignite the old Polybush vs. OEM debate, but I thought I'd try the Superpros and see how they get on.

Whilst I don't want to say a word against the garage that did my MOT in June, I'm surprised they didn't say anything about how rusty the spring seats and retainers were. There wasn't much metal left, and it can't have happened just over the summer. Fortunately, anticipating this, I'd got new ones to fit. I've greased the bolts generously so I might be able to get them apart again one day.

A quick drive round the block disclosed some funny noises like deep creaks and groans, much to my dismay. However, a longer test drive with lots of speed bumps seems to have settled it down and it's now a lot quieter.

Tomorrow, weather permitting, I shall have a crack at the front ones.

Here's one of the offending items complete with the Britpart logo of doom:

I'm putting new suspension bushes in too. Partly, this job was prompted by me finding some slack in the bushes which join the rear radius arms to the chassis. So here's a picture of everything off:

The nuts at the end of the radius/trailing arms were a bit of as struggle to undo. The poor old Milwaukee impact wrench rattled the rust off but didn't shift them. The 3/4" breaker bar and socket merely twisted the radius arm. I was wondering how to cut them off, but the nuts live in a recess in the bracket at the side of the chassis and are hard to get at with grinder or saw. Hmm. Fortunately, a freshly charged battery on the impact wrench did the trick, and easing the nuts back and forth half a turn eventually loosened them sufficiently to unscrew. Phew.

Reassembly was a lot quicker. Nice new springs and shocks in position:

I've got it some posh Koni dampers. You can see the new radius arm bush too. This might well re-ignite the old Polybush vs. OEM debate, but I thought I'd try the Superpros and see how they get on.

Whilst I don't want to say a word against the garage that did my MOT in June, I'm surprised they didn't say anything about how rusty the spring seats and retainers were. There wasn't much metal left, and it can't have happened just over the summer. Fortunately, anticipating this, I'd got new ones to fit. I've greased the bolts generously so I might be able to get them apart again one day.

A quick drive round the block disclosed some funny noises like deep creaks and groans, much to my dismay. However, a longer test drive with lots of speed bumps seems to have settled it down and it's now a lot quieter.

Tomorrow, weather permitting, I shall have a crack at the front ones.