v8250

Well-Known Member

- Posts

- 6,872

- Location

- Deepest Darkest...

Oh yes I have had that joy before, 5min to get the old one out and new one in with the puller you have pictured and then 1.5h fiddling with the spring clips with everything covered in grease trying to get the rubber to stay in place only for it to split 6 months later!

Here's a trick to make this job easier, use masking tape to hold the boot in place when fitting the retainer spring. Once retainer clip in place remove masking tape + buy boots from Polyboot.com and/or Gwyn Lewis, he sells the excellent Polyboot.com boots as kits for Land Rovers

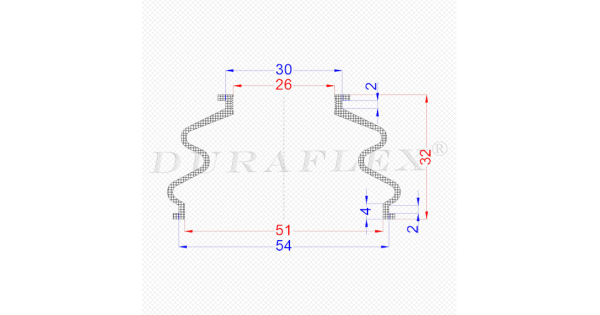

SEARCH BY SIZE

Ball Joint Boots and Tie Rod End Boots by Dimensions The search by size gives you the opportunity to find suitable dust boots, when you can't do that by just searching by make and model. For your convenience, the ball joint boots and tie rod end boots are split in 2 groups - by color and h

polyboots.com

polyboots.com

Steering Items – GwynLewis4x4.co.uk

gwynlewis4x4.co.uk

gwynlewis4x4.co.uk