Update, has been a while as was away on my holidays. Spent the weekend dodging the rain and getting very muddy clambering under the disco in the process.

Marked up and removed rear prop:

Disconnected the rear of the front prop and moved it out the way. The prop shafts compress to allow removal.

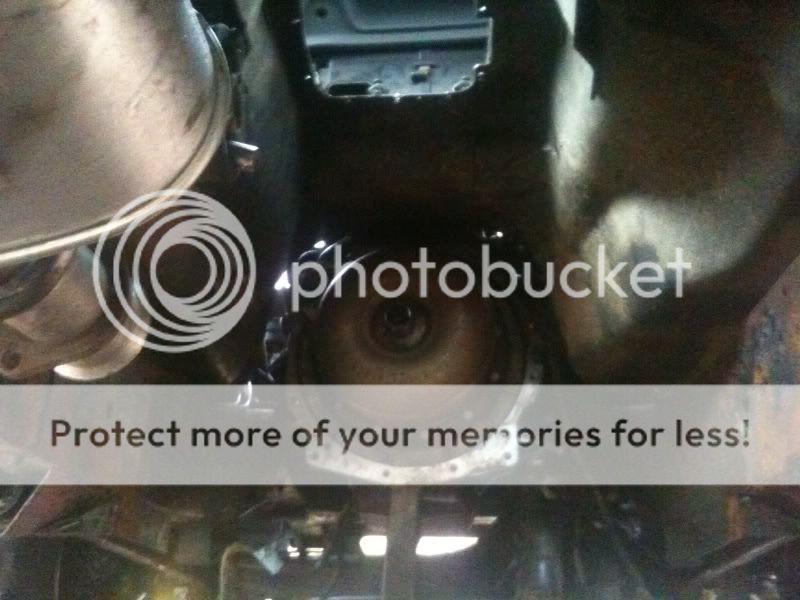

Marked up the torque convertor against the flywheel through starter motor aperture:

Removed washer reservoir to allow access for breaker bar:

and removed 3 out of the 4 bolts which hold the torque convertor to drive plate:

Make sure you use 1/2" hex shaped socket as these were ruddy tight on mine and one has rounded off which is going to be a mare to remove at later date. Also they are easy to drop into the casing on removal, as I learnt after now having one stuck somewhere behind the flywheel!

Removed handbrake cable which is held in by a metal slide clip:

and pulled cable through under the vehicle:

Disconnected 2 wires from top of the box, blue wire was o/side black n/side:

Disconnected lead in engine bay which connects to sensor in top of bellhousing:

Removed bracked which holds oil cooler pipes and moved them out the way:

Supported gearbox and engine with individual jacks:

Removed gearbox support brackets, 4 bolts on either side:

*

and then the crossmber:

Made a start on the bellhousing bolts, bottom first. Bolts are 1/2 inch - same size as the ones removed from torque convertor, again these were ruddy tight so used hex sockets:

One of the bolts on o/side holds dipstick bracket:

Then I lowered the box by dropping both jacks in order to get access to the top bellhousing bolts, tilted the engine us far as I could without crushing the ancilliaries behind the head:

Probably not advisable but I did this without use of a hoist, the box is bloomin' heavy to drop on yer own which wasn't made easy by working on gravel:

Tadaa!!

I found the easiest way to move the unit once on the floor was stick it on some carpet and drag it around.*

and at least I now know exactly which model# to go for with it being EDC:

That's it so far, next step to somehow get the TC off to get access to sort the rear crank seal, then buy a hoist and replacement box.. oh and wait for my back to recover!!