stopover

Active Member

- Posts

- 852

Flex plate gone on my 4.6 Thor. Any tips would be welcome

Matches and petrol?

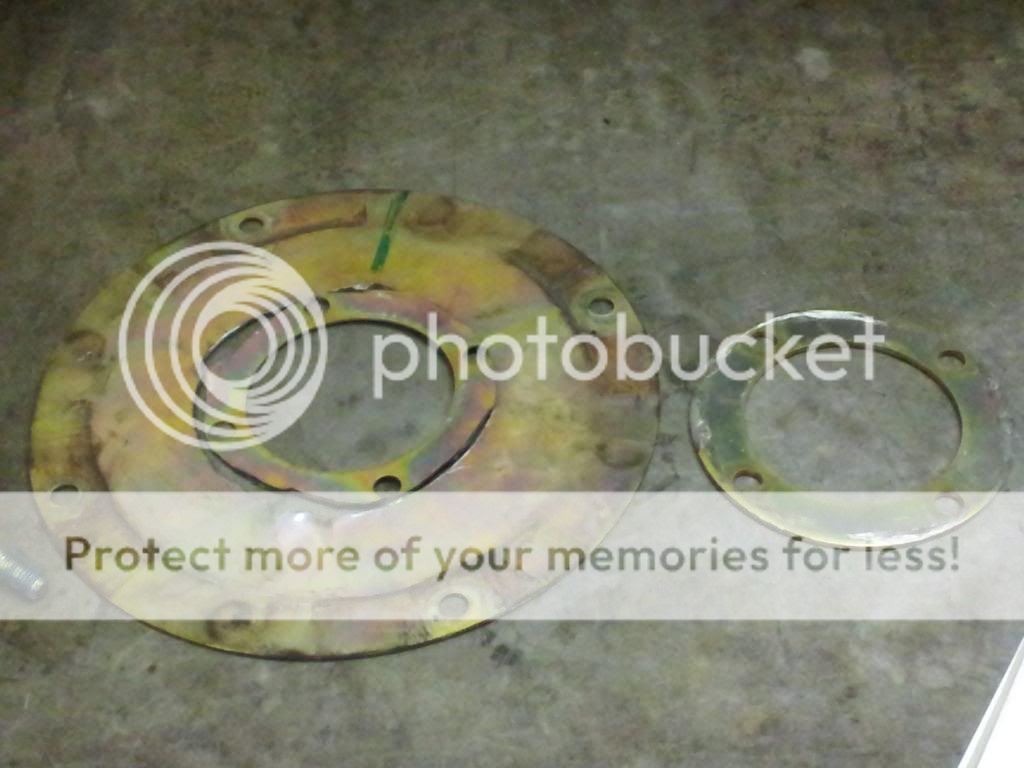

What pictureHave the gearbox out and the flex plate is split all the way round. See picture.

Question: Does anyone know the torque figure for (a) the four bolts that secure the flex plate to the flywheel spigot and (b) the four bolts that secure the flex plate to the torque converter.

I have heard that a revised figure was introduced??

What picture

A revised torque figure wouldn't make any difference to a torn flexplate like that. imho.

Just fit a new plate and do the bolts up tight (with threadlock).

Anyone with real knowledge please help.

40+ years as a time served commercial vehicle mechanic and plant mechanic, is my knowledge, trade and living.

Does your manual state a different torque figure for dry and lubricated bolts as well (also does it state which grade of thread lock to use)???

How long have you been messing with motor cars???

How many total engine, gearbox and a diff rebuilds have you done in the last 40+ years??????????

And has your torque wrench calibration been tested within the last 12 months???

And you still say just "do up tight with some threadlock" !!!

plus medium strength Locktight

ps just found this:

Welcome To LandyZone, the Land Rover Forums!

Here at LandyZone we have plenty of very knowledgable members so if you have any questions about your Land Rover or just want to connect with other Landy owners, you're in the right place.

Registering is free and easy just click here, we hope to see you on the forums soon!