olsver

Member

- Posts

- 63

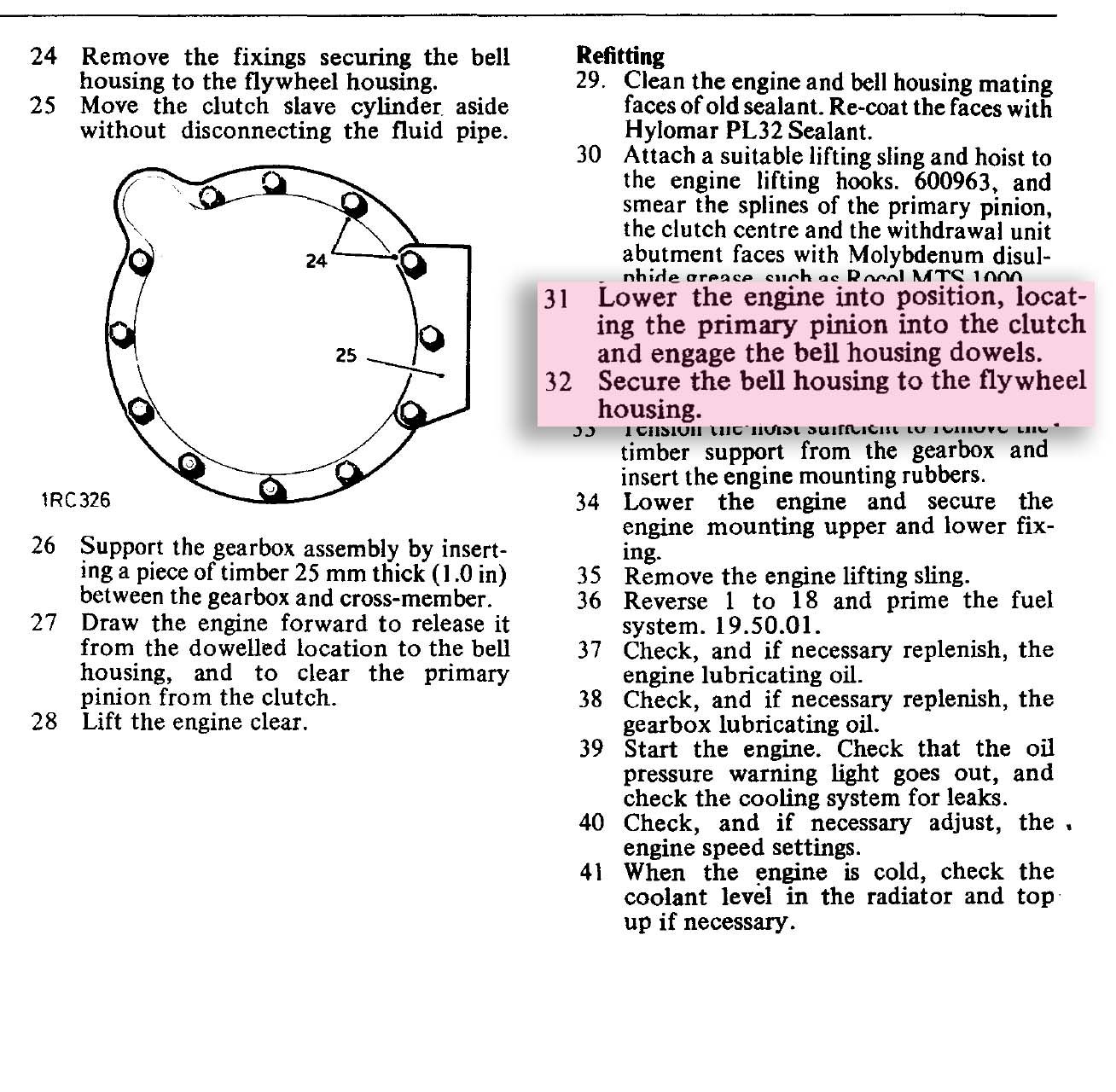

Does anyone know the torque and recommended fitting of the bell housing to flywheel housing. From the instructions in the workshop manual it could be anything from finger tight and upwards.

I is aluminium so I was planning fitting with flat washers, blue Loctite and done up spanner tight (hand held half way down the shaft). Am I far off?

I is aluminium so I was planning fitting with flat washers, blue Loctite and done up spanner tight (hand held half way down the shaft). Am I far off?