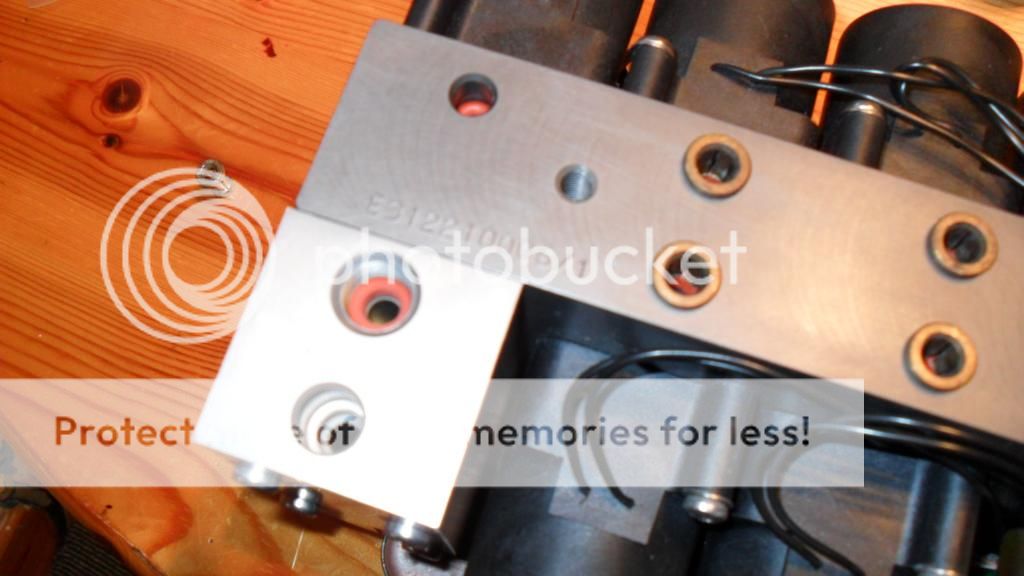

Valve Block

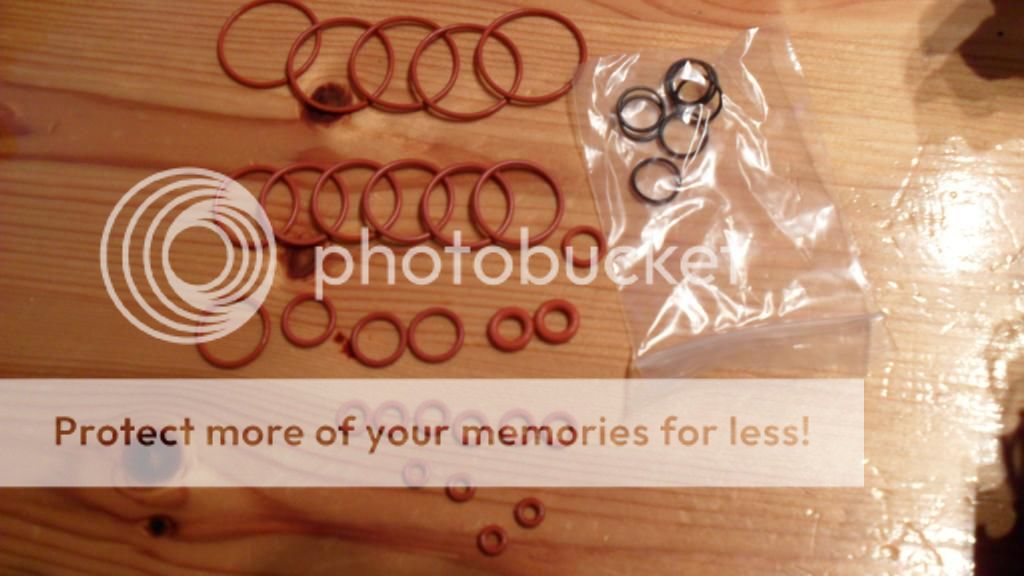

Rang the suppliers of Arnott, he is saying its a leak from the valve block, O ring possibly? the o/s/f is not going up as it should, its taking forever, but holds air for a few days, no leak in the back itself or where the pipe attaches to it, dont know what to do now!! gona do a search on how to fix it, have a spare block so might just try and do a swap???

Rang the suppliers of Arnott, he is saying its a leak from the valve block, O ring possibly? the o/s/f is not going up as it should, its taking forever, but holds air for a few days, no leak in the back itself or where the pipe attaches to it, dont know what to do now!! gona do a search on how to fix it, have a spare block so might just try and do a swap???