Now for something a little bit different.

I intended to fill the rear compartment with a small fridge, 240v inverter and aux sockets.

For obvious reasons it will need to be sealed and water tight.

The fridge is large enough to fit two 6 packs in it. Almost as essential as a tow rope

The fridge works by thermo electric as opposed to gas.

So far i have started to build the out edge of the contact surface of the cover.

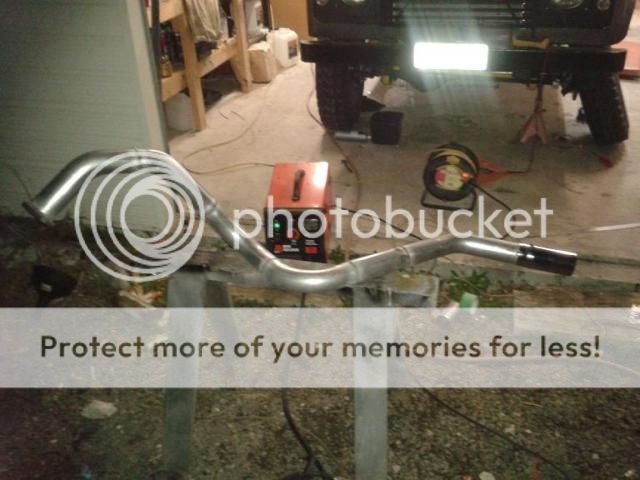

This photo shows the items i will be fitting into the compartment

First task was to strip down the fridge so that it can fit into the space. The front cover, lid and tie down loop have all been removed.

I have screwed the power converter to the side of the fridge.

This photo shows the remaining space in the compartment. As luck would have it the fridge is around only 2mm away from being flush with the height i require.

Next job was to make an inner cover to keep things looking neat. I have run out of time this weekend to fit the 12v power sockets and fridge controls. I want to complete all drilling before spraying it.

Anyway i will post more photos once complete, however it gives you an idea on how it will all sit. It makes a nice change to have fun building something a little different.