Dr_evil

Banned

- Posts

- 29,535

- Location

- Perched on the naughty step

my local fabricator that does all of my work is more agricultral

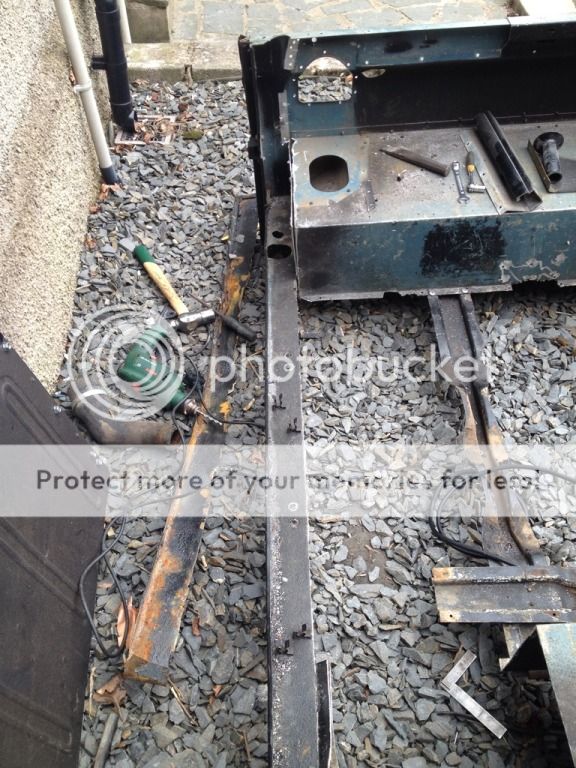

my gearbox and engine mounts are made of 5-8mm plate haha

mig welding ali? isnt that some sort of dark art? haha

and well my TIG work is just horrendous lol

My tigs not too bad now, not great but neat enough to look good, been practicing when I get the chance, will be tig welding my series tree sliders together or at least the welds that are on show, the others will just get a blast from the big butters mig

mig welding ali google it

your gearbox is a bit beefy though isn't it ? or are you running a normal LR one with the 6BT ?