Alibro

Well-Known Member

- Posts

- 7,028

- Location

- Northern Ireland

I had to take off the inlet manifold yesterday so I could fit a Renault thermostat and was disgusted to see the crap building up again already after only a thousand miles or so. So being the tight so and so that I am I decided to have a go at DIY blanking the EGR. I have a spare EGR so figured, what the heck. I could order a nice shiney new bypass kit but where would the fun be in that?

This is what mine looked like before I cleaned it a couple of months ago, the spare wasn't as bad but I'm including this photo to show the valve mechanism which obstructs air flow. Removing this mechanism will probably make little difference to a Turbo car with forced induction but it pleases me so that's good enough reason to do it.

This is what was left after I had a go at it with a hack saw.

After dremelling the sharp edges.

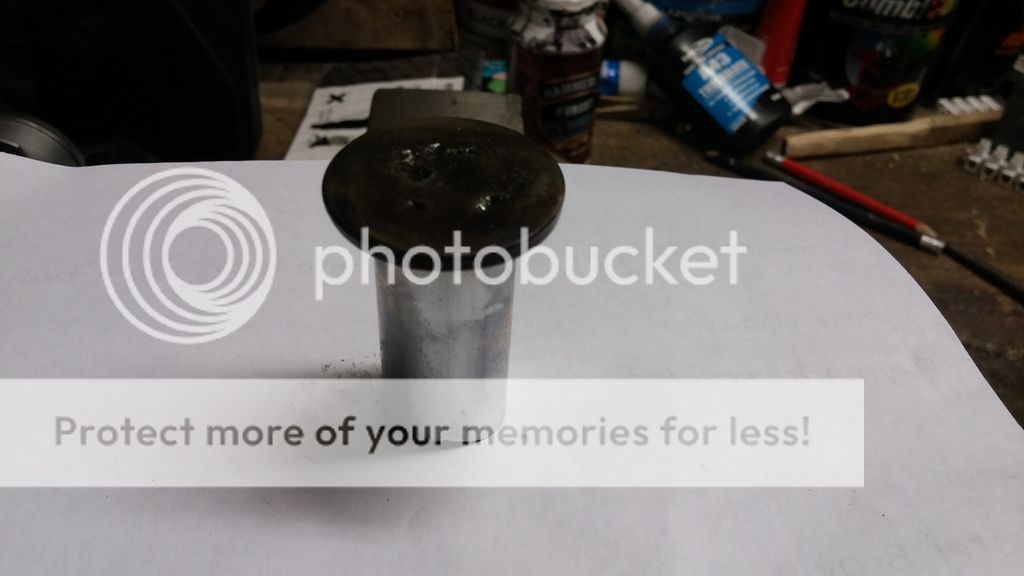

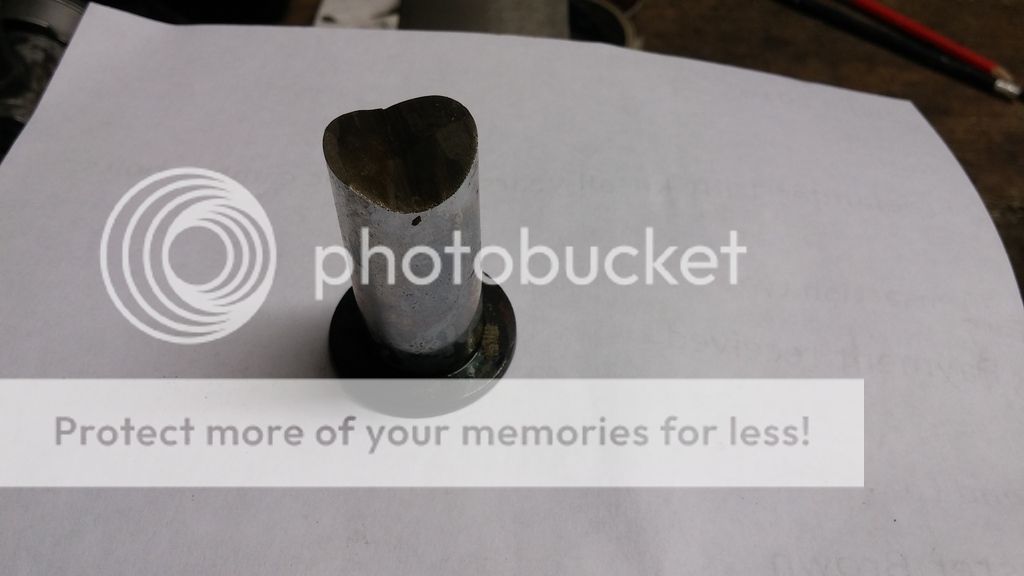

With the valve stem cut away the gate for exhaust gasses just fell out. I was hoping it would stay in place but now there is a big hole left which may or may not cause turbulence, but I'm not taking the chance. I've cut a bit out of an old strut which is close to the right size and shaped the end to more or less follow the inside curve of the EGR. I plan to weld the washer in the photo onto the end of it so it is a tophat shape and will be clamped in place by the normal EGR exhaust connection.

I was hoping it would stay in place but now there is a big hole left which may or may not cause turbulence, but I'm not taking the chance. I've cut a bit out of an old strut which is close to the right size and shaped the end to more or less follow the inside curve of the EGR. I plan to weld the washer in the photo onto the end of it so it is a tophat shape and will be clamped in place by the normal EGR exhaust connection.

I will have to grind a bit off the exhaust end of the EGR to make room for the washer but not sure how much yet so will wait until I have it welded up then see.

This is what mine looked like before I cleaned it a couple of months ago, the spare wasn't as bad but I'm including this photo to show the valve mechanism which obstructs air flow. Removing this mechanism will probably make little difference to a Turbo car with forced induction but it pleases me so that's good enough reason to do it.

This is what was left after I had a go at it with a hack saw.

After dremelling the sharp edges.

With the valve stem cut away the gate for exhaust gasses just fell out.

I will have to grind a bit off the exhaust end of the EGR to make room for the washer but not sure how much yet so will wait until I have it welded up then see.

Last edited: