Hi Jonny

Yes it has been a very quick thread this one!!

So here we are, new day, fresh head, clear view.

The plan is this:

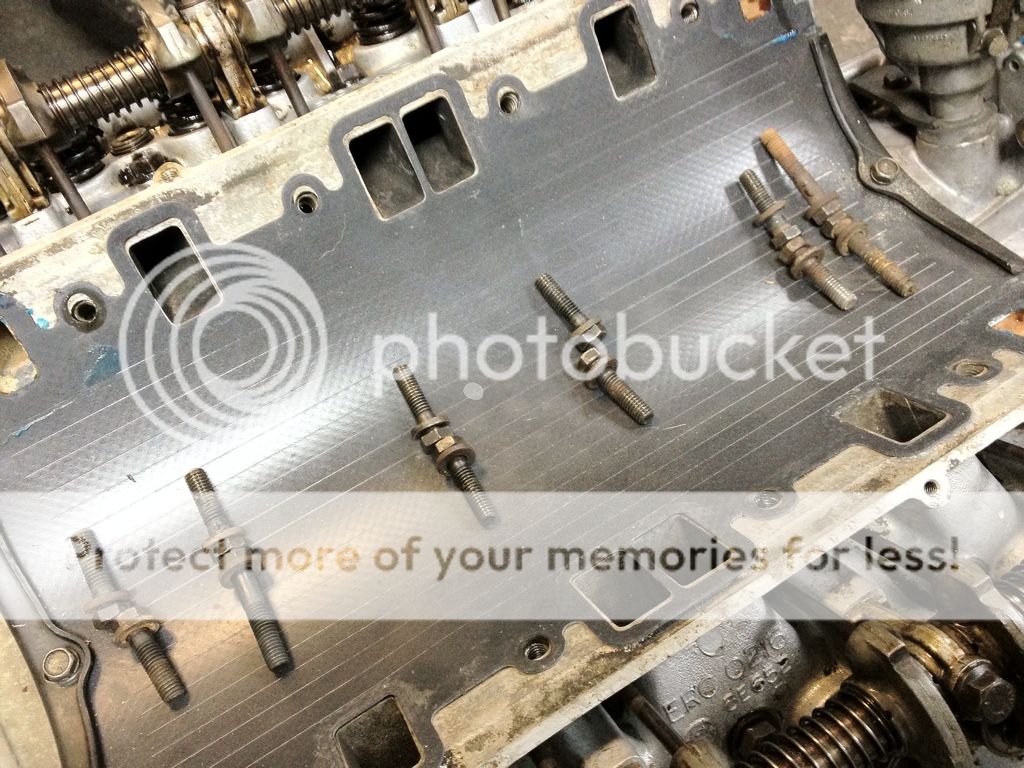

Remove inlet plenum, pull injectors, look in holes.

Then decide what to do, whether it is worth opening the ports up for the sake of the little piece.

Please note I have TIN headgaskets and COMPOSITE valley gasket.

If I do decide to do the work, it will be an in situ port opening, simply using a pneumatic finger sander to remove material around the port opening, mainly at the top, to reach the gasket profile. I am quite happy there will be sufficient room to work. This will be done at TDC in firing order to ensure valve is closed, then good wash out with brake cleaner and compressed air etc.

I will consider opening the ports on the inlet mani slightly perhaps, but might not bother. I am also considering taking some length off the intake trumpets, perhaps 15mm. I think a little extra clearance will help with top end flow rate a fair deal, and it's an easy on-the-bench task.

The valve gear will not be touched, it is a standard cam in a land rover engine, and therefore it will have to do.

When I feel like having some fun I will tear down that engine I have waiting in the wings and have a play with a higher performance build, purely for pleasure and with no time constraints of getting it back in a vehicle.

Jonnyt thankyou again for contributing, I think we need to face facts that serious ****inh about is not worth it given the weight of this vehicle.

The Megasquirt will heavily improve drive ability and tune, but I think the mechanicals will be in sufficient shape to support the Megasquirt adequately.

I am quite keen to make sure the injector spray is happy though because my fuel will be quite precisely metered now, so need to make sure I get the best atomisation I can.

Anyway, first step, injectors out and see what's what!

Thanks again everyone, truly smashing help