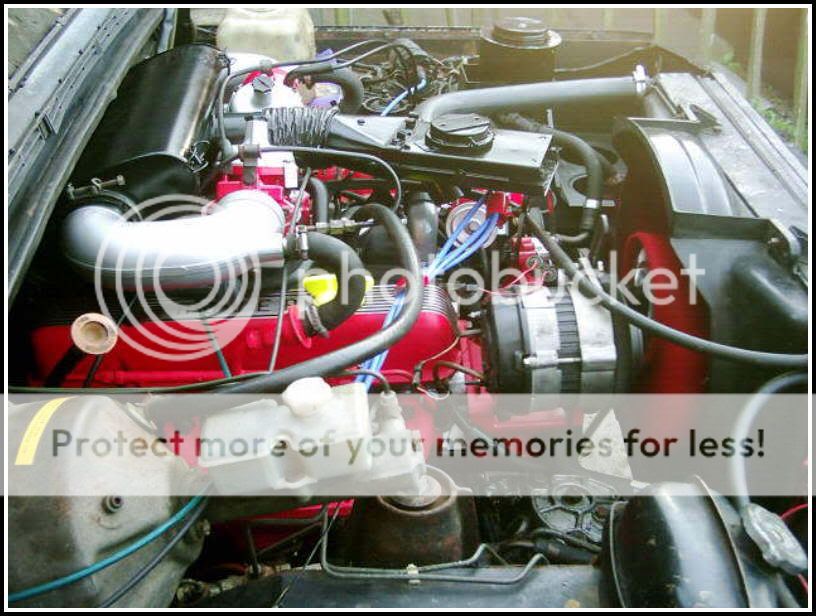

Your no madder than me; I rebuilt the motor in my first Rangie:-

A month after it was installed, the troll (now very X missis) buggered off with it and trashed it!

However!

When it comes to RV8 cams, the choices are myriad, and the descriptions and numbers bewildering;

The Piper 265 is described as a fast road / race cam, and the number, 265, denoting 265 degrees of 'duration' between the valve opening and closing, would be deemed quite 'hot'....

However the original Low comp carb motor's STANDARD cam had a 285 duration cam, which technically has a longer duration than the Piper 265, yet is described as a 'soft' cam.......

Reason is, that the Piper 265's shape is different (unsurprisingly!) valves open later, and close earlier, but the cam ramps them open further and faster and holds them wide open for longer, which is where we get into the technical talk of ramp rate and dwell angles, which are for the most part irrelevant, all we want to know is what works and what 'kind' of power curve to expect!

Rule of 'thumb' is that the hotter the cam, the more top end power you get, at the expense of low down power, and part throttle 'response' and clean running. The cam 'duration' gives a rough idea of how hot a cam is, becouse the longer the valve is open, all else being equal or near enough, more cylinder filling time it offers.

Not a strict rule, as said, Low Comp RR cam is longer duration than many a sprint cam, but works more often than it dont.

Now, I looked at a LOT of tuning options and all the cam-specs I could when rebuilding that engine; and the bottom line was I went for a new stock bump-stick.

And, to be honest, I would advise, on a 3.9, to use the stock cam as your bench mark; as said, its very well suited to the application by way of the charecter it offers, and the gain from an aftermarket 'high-torque' or '4x4' profile on THAT engine is small for the outlay, while moving to hotter profiles, such as a 'rally' or fast road profile, will give gains in mid and top end, but at the expense of bottom end power, which is the 3.9's forte.... its a motor that makes 75% of its available torque at or near tick-over, and provides the sort of thrust that makes such a big heavy barn door sized vehcile 'hustle' off the line, or upp a hill, or 'pootle' along a green lane on a wiff of throttle when others, especially diesel jokeys with thier huge resrves of imaginary 'low down torque' are making motors labour or scream!

As said, with a bit of careful building, and from a complete tear down you have a clean slate, you should be able to get first the original 'quoted' power of 185bhp, which I can tell you catagorically can be as much as 30% up on a tired old motor like mine, which I reckon is struggling to grunt out much over 120 at the moment.

Next, WITHOUT going wild on mods, you should be able to push that up, respectably towards or over the 200 mark, and keep the motors essential nature and loverly elastic band torque curve.

First of all the heads; a mild porting job; you dont want to go over sized on the valves or ports, as the smaller holes give higher flow velocities at plow engine speeds and smaller throttle openings, which is good for bottom end power and 'driveability'.

But, the ports can benefit from being 'cleaned up' and the port and combustion chamber volumes 'balenced' so that the air speeds through the ports are all the same and the compression ratio in each cylinder is likewise the same.

Next, compression ratio; stock figure is 9.5:1, and as said, first job is to make sure it is, second to increase that by as much as you dare!

Personally, as I run on LPG I'd optimise for gas and be a bit braver, and head for something in the order of 11:1, as LPG can 'stand' it having a higher octane rating than 95RON unleaded. would probably mean that I'd need to use an ignition advance module to exploit it, and be able to run on regular petrol without pinking, and I'd probably have to ritchen up the petrol mixture to add some margin for safety robbing me of petrol ecconomy and power, but hoping to use LPG more than FPF, pro's should win for me..... but I dont know if you intend gassing it.

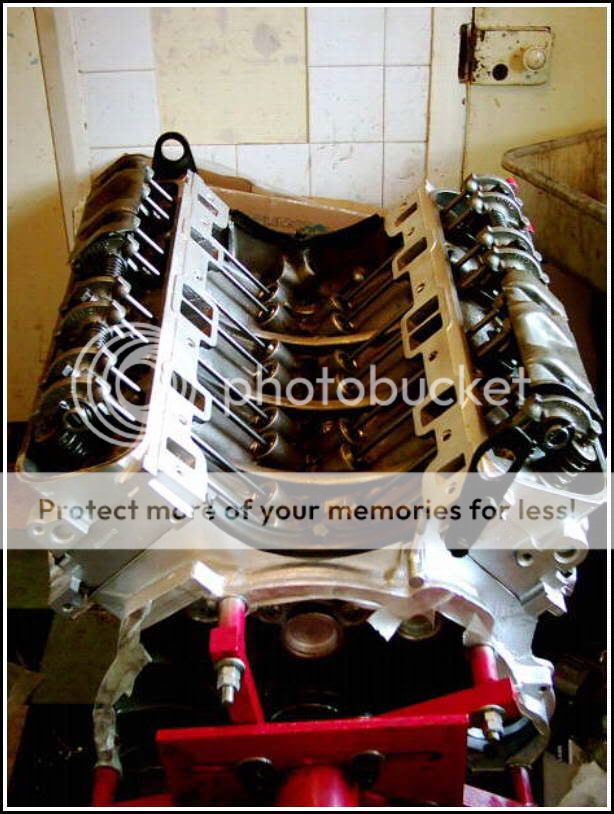

Block, pistons, rods and crank:

When doing a 'built' engine, always good to make the bottom end as togh as you can; first to put as much reliability and life into it as you can, and second so it is best able to stand any extra strain from added power you might find elsewhere.

Lightening cranks and flywheels used to be the 'done thing', and I suppose people do still do it.

On a Range Rover though, advantages of a lightened crank are minimal, and if you have an auto transmission you dont actually have a flywheel to lighten, and if you DID try lightening the rotary mass or moment of inertia of the bottom end, that ruddy drum of oil called a torque converter would pretty much negate any benefit.

On a lighter car, a lightweight crank & flywheel can have a really big effect on the way the car resopnds to the throttle and accelerates, as the lower reciprocating moment of inertia saps less of the available power to accelerate it, but a Range Rover weighs nearly five times what a mini or old M2" escort did, which rather masks the advantage, AND that added mass is there for a reason on a Rangie, its there to damp drive line 'shunt' as you change loading especially between gear changes, where all the mass in the car has a much begger effect on the drine train.

So, I'd not be inclined to 'mess' too much with the crank, though again, worth getting one 'prepared' by way of stress relieved after grinding to make sure that there are no discontinuities in the casting or from machining / grinding that might weaken it.... speed shop you entrust it too, would probably do that as part of a 'stage 1' lighten and balence job, rather than a full race job taking half the counterweights off and wedging them.

Con-Rods! Stock rods are pretty tough, but they are heavy, but then race rods are effoff expensive. Like the crank and head, my advice would be to stick to the stockers, but 'prep' them; again, be down to a speed-shop and what they suggest and reccomend, but basically, you want them balenced end over end and against each other, then stress relieved by shot peening to remove discontinuityies.

Seem to recall that the big end bolts are an interference fit in the rod, and I'd want new studs in there, before balencing.

Block; derigeur these days to go for relinering rather than re-boring, and, for the bigger bore motors top hat liners.

I'd think long and hard about that one, as top hat liners are an expensive way to go, but do make the motor bullet-proof, on that side of things, and if your bores are worn far enough that you cant get away with over size rings to accomodate the rebore and need over sized pistons, part of the added cost of relinering to standard size, can be clawed back by not having to shell out for new slugs......

Pistons; again, prepped standard slugs; a little skirt work cant hurt, but probably not really worth the effort unless you are seriousely tuning the motor; what is worth while though is prepping the top end. Stock pistons have a 'tin-can' dish profile; and when built up, tolerences can see them sitting at different heights beneath the block deck at TDC, giving different compression ratios.

That rim around the piston also does a thing called 'squish' which is that when it gets close to tdc, the small clerence between the piston and head 'squishes' the charge in that gap into the combustion chamber, causing turbulance that aids combustion mixing.

Process of 'deck-heighting' taking a little metal off the block so that the pistons all protrude slightly, then machining them flush to the new block height is a really good thing to do.

But having done so, the pistons need the dish chamber volumes balencing, as the combustion chamber volumes to correct the compression ratio.

On which topic, worth a thought about what gaskets to use, and for me, the tin-plate gaskets are far better, particularly on a detail built motor where the tolerences are all more critically applied, than the squashy thick composite versions, and if you are setting the motor up to run sqush, you REALLY dont want that added gap between the slugs and head robbing you of the effect.

But, you need to be sure that you set the combustion chamber volumes and piston dish volumes for the compression ratio you want, with the head gaskets you intend to use.

OK! So, so far, pretty standard practices for a built engine, and nothing drastically OTT or wild.

Vernier Timing set: If you have had the block deck-heighted, and gone to that level of detail in building the bottom end, then this really is pretty much essential, to get the cam timing set to optimum.

On an OHC engine, it would be even more so; as the cam chain round between the crank and the timing gear, which, having deck heighted the block would be closer together, meaning that the run on one side of the chain would be shorter, adjusting cam timing.

On an OHV engine, not so critical, but you need to be aware of it when you come to look at the rest of the valve train, becouse the push-rods and tappets are going to be that tad longer than needed.

Lifters SHOULD take up that difference, but if you are building a V8 critically, worth doing it all to the same level of diligence and shimming the tappets to get the right pre-load on them all.

On which topic, theres a whole load of different lifters available, and it was the early lifters which demanded that lazy long duration cam, as they simply werne't that effective! They also had a tendancy to 'jam' in thier guides, and limited the rev cieling to about 5K.

The stock lifters in the 3.9, though, are not bad; they are lighter and more effective than the earlier versions, and are 'good enough' for what you can get a stock 3.9 to rev to...... in my case, I've only been brave enough to nudge 6K at idle, and not got it much over 5 1/2 on load, which is a lot more than the 5K and lifter jam people used to predict, though they probably are right that for 'sustained' use over 5K you really need a more advanced valve train.

So following the philosophy of a critical built 'standard' engine, they'd be my first choice, as siad critically shimmed for pre-load, BUT, there is a light weight lifter in the Rover parts catalogue that was used in the Morgan & TVR big bore engines, that is reckoned to be good for 7,500rpm reliably, and if not too inordinately expensive might tempt me.

Again, stock push-rods are pretty good, they dont have any fancy forms in them, so theres not much to say about them, and as they are drawn steel not cast, little that can be done or worth doing by way of lightening or peening or anything.

Only real option here would be to swap them out for hi-po versions in lightweight alloy or carbon-fibre; but for the expense, and gain, unless going to high ratio roller rockers, probably not worth the doing, and even then, high ratio rockers lower the rod loading, so even then not particularly essential on 'soft' cam.

Which brings us to those rockers, and having vaunted the benefits of High ratio and roller items, I wont again, except to say that they do do a good job, and gibe you the added lift, without making the rest of the valve train, by way of lifters and push-rods work any harder, as they get to move the smaller distance of the softer cam profile.

If I didn't use Hi-Ratio rollers, then it would be down to the standard items, which I have to say aren't bad, and are actually a high-ratio rocker; I cant remember if they have a 1.25 or 1.33:1 'advantage' at the valve over the cam, but they do shove the valve further than the cam shoved the rocker, so when I have been talking about Hi-Ratio roller rockers, I probably ought to have clarified that by saying 'Higher' ratio Hi-Ratio rockers... but you get the gist!

Stock rockers are light weight aluminium with reletively short arms and reletively large shaft. So they tilt a greater angle for the same amount of lift, but they dont have a very big radius in either direction, so dont have a large moment of inertia..... in short, for stock rockers they are pretty 'neat', and hard to beat....

There's not much then to be gained from trying to lighten of balence them, though they do benefit from being peened to stress relieve them, as they can craze and crack around the push-rod cups.

But do make sure you get GENUINE ali rockers, if you go for standard items; the common 'pattern' parts are I think steel and weight almost twice as much, which is not good on a critical build.

And that is pretty much it!

Might seem pretty 'tame' but time and again, I've proved and re-proved to myself that the closer to stock you stay the more useful the engine tends to be; giving modest peak power, but usualy a heck of a lot more 'useable' power, by which I mean power in the low and mid range or at part throttle, where and when you need it; so you get more power more often, which means a faster car!

Also tends to be a darn sight more reliable and an awful lot less hassle to set up!

Essentially a semi-blue-print engine, built to pretty much standard specs with standard parts, by way of cam and valve train, simply put together with a very high level of attension to detail.

Essential elements in there are:-

- Compression ratio check / increase

- Standard Cam, to maintain basic engine 'charecter'.

- Vernier Timing Set to allow critical timing of the cam at build and during service

- Critical assemblty of ALL components, with particular attension to lifter pre-load shimming

Optional elements in there are:-

- Balenced & Stress Relieved Crank

- Balenced & Peened Con-Rods

- 'Prepped' block by way of relinering / re-boring

- Deck-Heighting of pistons & block

- Balencing of combustion chamber volumes in head & piston dish

- 'Mild' porting & balencing of port volumes in head

- Possible use of TVR lifters

- Possible use of Hirer Ratio Rockers

- Possible use of light weight push-rods

Taking it to another level:-

- Bgger Valves

- Hotter Cam profile

But at that point you are going beyond finding everything you might have as standard and shifting the compromises, so you'll start gaining top end power at the expense of bottom end and driveability, and giving yourself more work to set the engine up.