Hi,

This is my second post so apologises if in the wrong place.

I am looking to rebuild my 2.25 Diesal 1973 Series 3 engine.

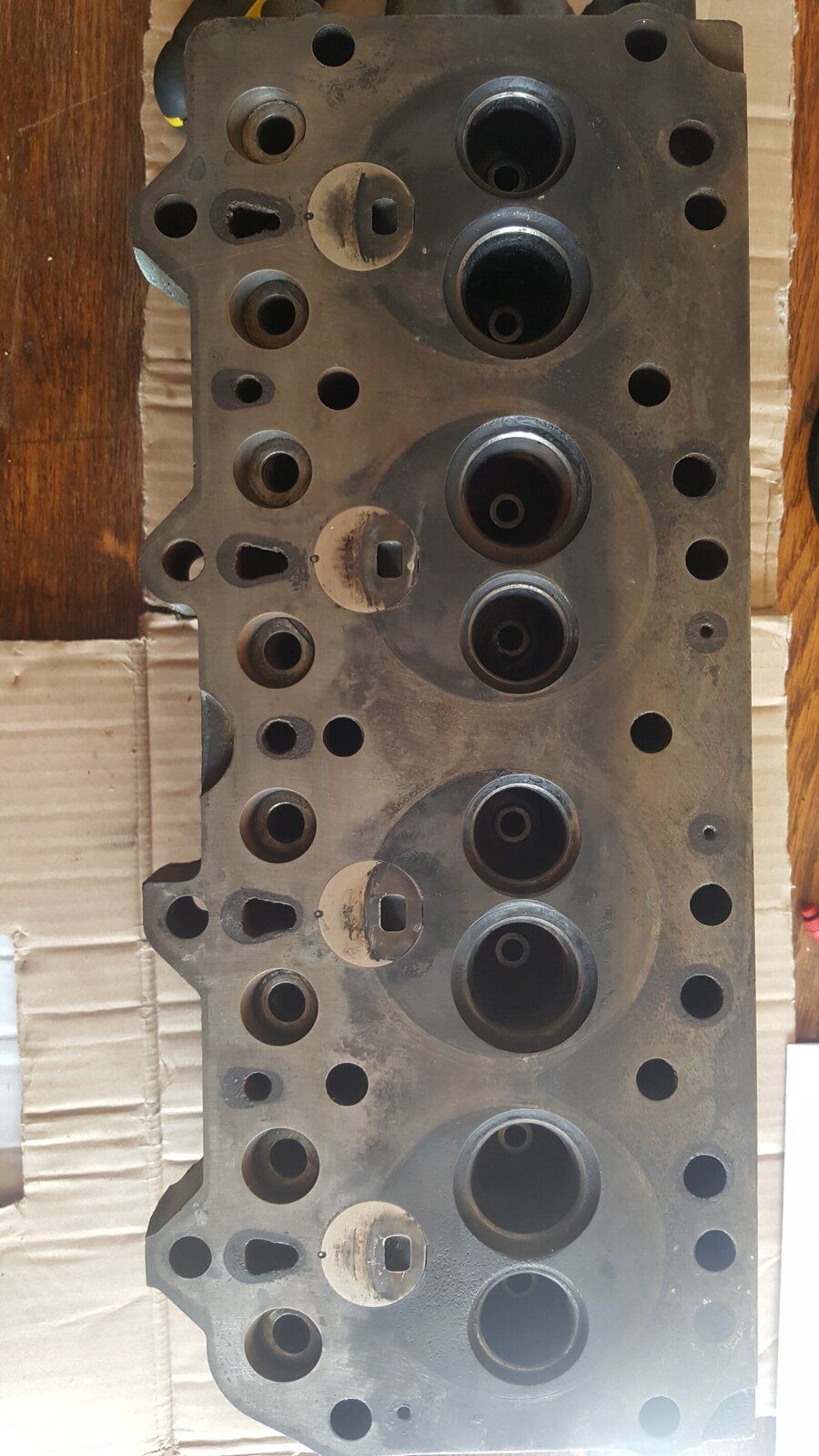

I have the head off and on inspection there is some pitting around and between the valves on number 4. There is also very small (just visible) cracks on the hotspot.

My question is what would cause this? I would be looking to use this head and get it tested and rebuild it. In others experience is this normal? Is it worth getting it tested or is the head beyond being saved and best to replace?

Thanks all in advance, James.

This is my second post so apologises if in the wrong place.

I am looking to rebuild my 2.25 Diesal 1973 Series 3 engine.

I have the head off and on inspection there is some pitting around and between the valves on number 4. There is also very small (just visible) cracks on the hotspot.

My question is what would cause this? I would be looking to use this head and get it tested and rebuild it. In others experience is this normal? Is it worth getting it tested or is the head beyond being saved and best to replace?

Thanks all in advance, James.