Another how-to, this time it's changing a rear driveshaft oil seal...

Things you will need:

Good ratchet.

12mm six sided socket - for the brake caliper

13mm 12 point socket - for the caliper carrier

15mm six sided socket - for the hub

BFH or rubber Mallet

Lithium grease

Copper grease

Kitchen roll or other cleaning material

WD40 OR Plus Gas OR other release oil of your choice

Slide Hammer OR Large Punch OR Sharp Drift - to get the hub to break off the axle (in order of preference)

Pry Bar - to lever the hub out

Wire brush - to clean up the hub and axle mating faces

Phillips screw driver - to remove the brake disk

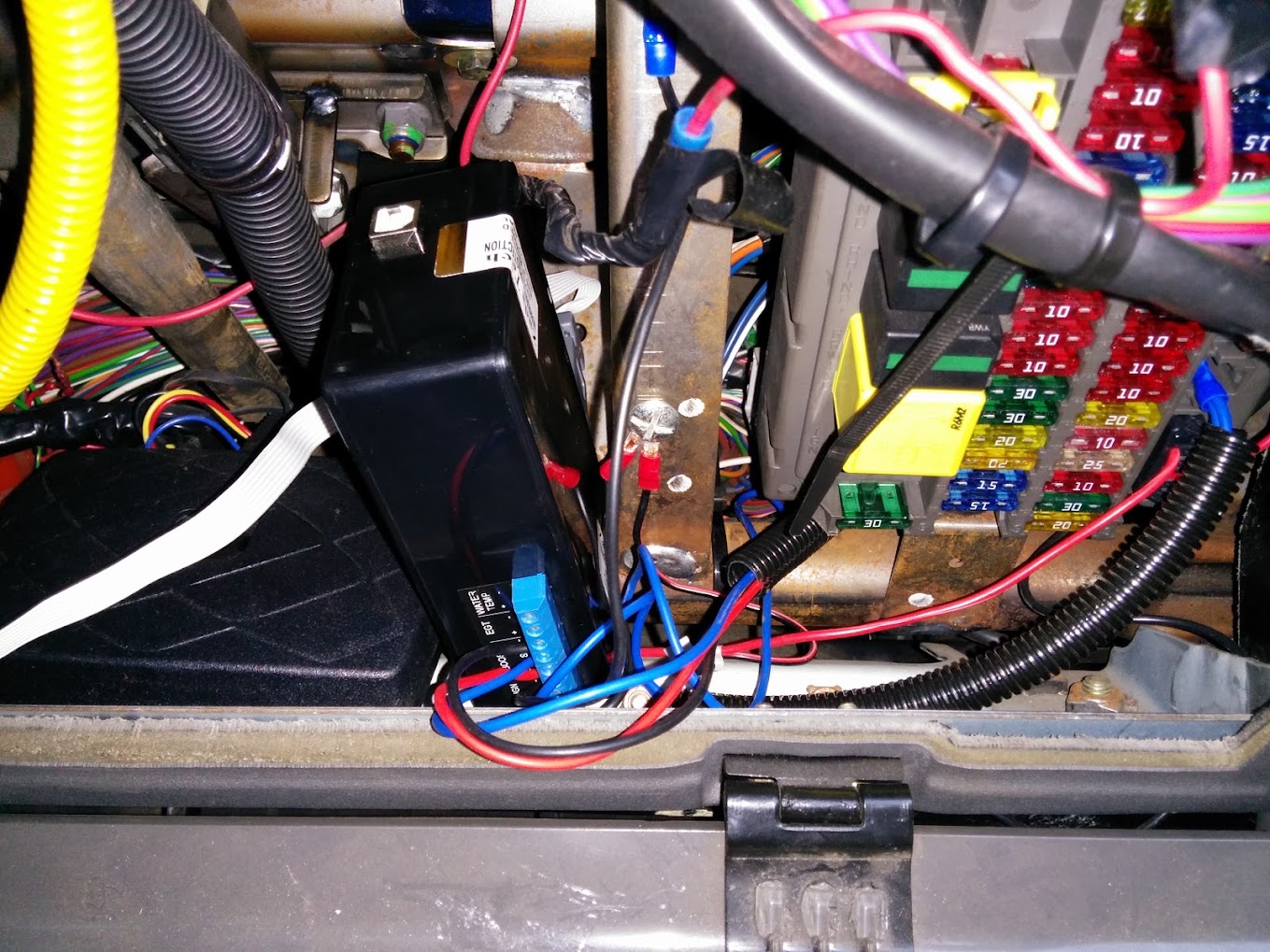

75W90 Diff Oil in case you spill any (I use Casrtrol Syntrans)

A new O-ring part number FTC4919

Something comfy to kneel on... some decent gloves... overalls.... etc

You may also need a dremel/small wire wheel to clean up the o-ring channel on the hub.

First thing is to jack the vehicle up as high as you can at the affected side, this will prevent most of the oil running out of the axle tube. The car is in gear, handbrake on, wheels chocked. Jacked on the trailing arm, with a stand under the axle and another under the trailing arm for safety. Once the wheel is off stick that under the back end for additional protection from the vehicle falling - can never be too safe imho.

Once the wheel is off you can remove the caliper securing bolts with the ratchet and 12mm socket, crack them both off before fully removing them - makes it easier

With the bolts removed I sat the caliper up on my exhaust - don't strain the brake line!

Remove the pads - remebering which went where - easiest way is to put the outer one further from the vehicle

Now using the 13mm 12 point socket and ratchet remove the caliper carrier bolts - you might need to persuade them off with a breaker bar or the BFH. Mine came off easily because I'd recently overhauled the brakes. (feel free to use release oil)

Remove the brake disk (rotor?) securing screw with a large philips/posi screwdriver, and pull the disk off - you might need to persuade it off with a mallet if it's been on a long time. (removing the break shield gives better access to do this, the hub won't spin with the handbrake on and the car in gear.

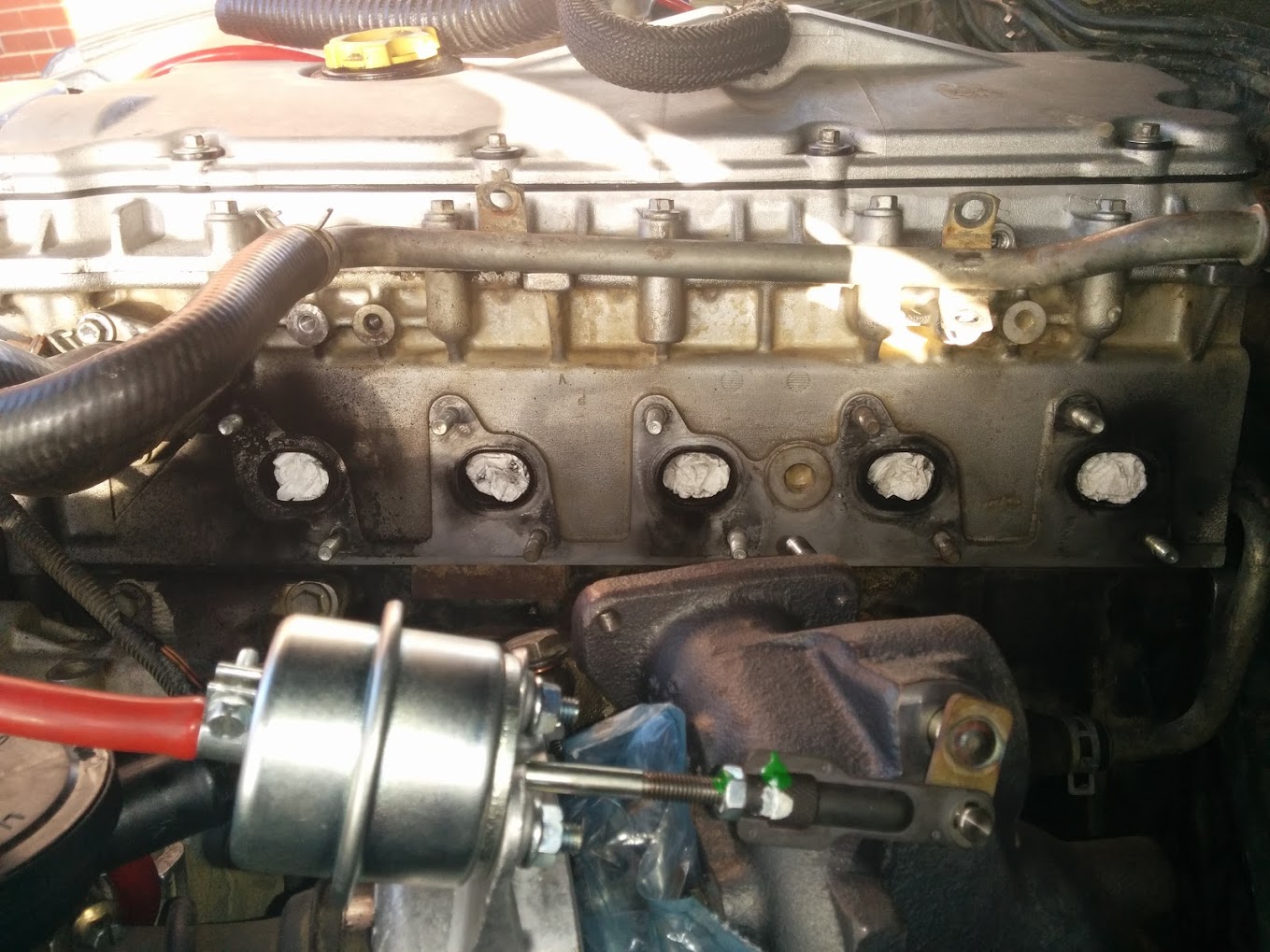

You can now clearly see the mess the oil leak has made, the hub is also looking quite corroded, at this point I'm pretty sure it's the one fitted at the factory 120K ago - rears tend to last longer since there's no additional pressure from the steering.

Here's the inside of the brake disk, also covered in oil

Clean them up as best you can, I used brake/clutch cleaner on the disk, and a wire brush and small flat head screwdriver on the hub - pay particular attention to the ends of the hub securing bolts, the cleaner these are the easier they will extract

Most of the nasty rust removed from the hub

Now give the bolts ends the good news with some release oil and set about getting them off - I used a BFH to break them off, be careful if you are doing this since you might break your ratchet - it's not really possible to get a breaker bar in to them.

It's VERY important to use a 6 sided socket here, you will easily round these old nuts off if you use a 12 sided one, you have been warned!

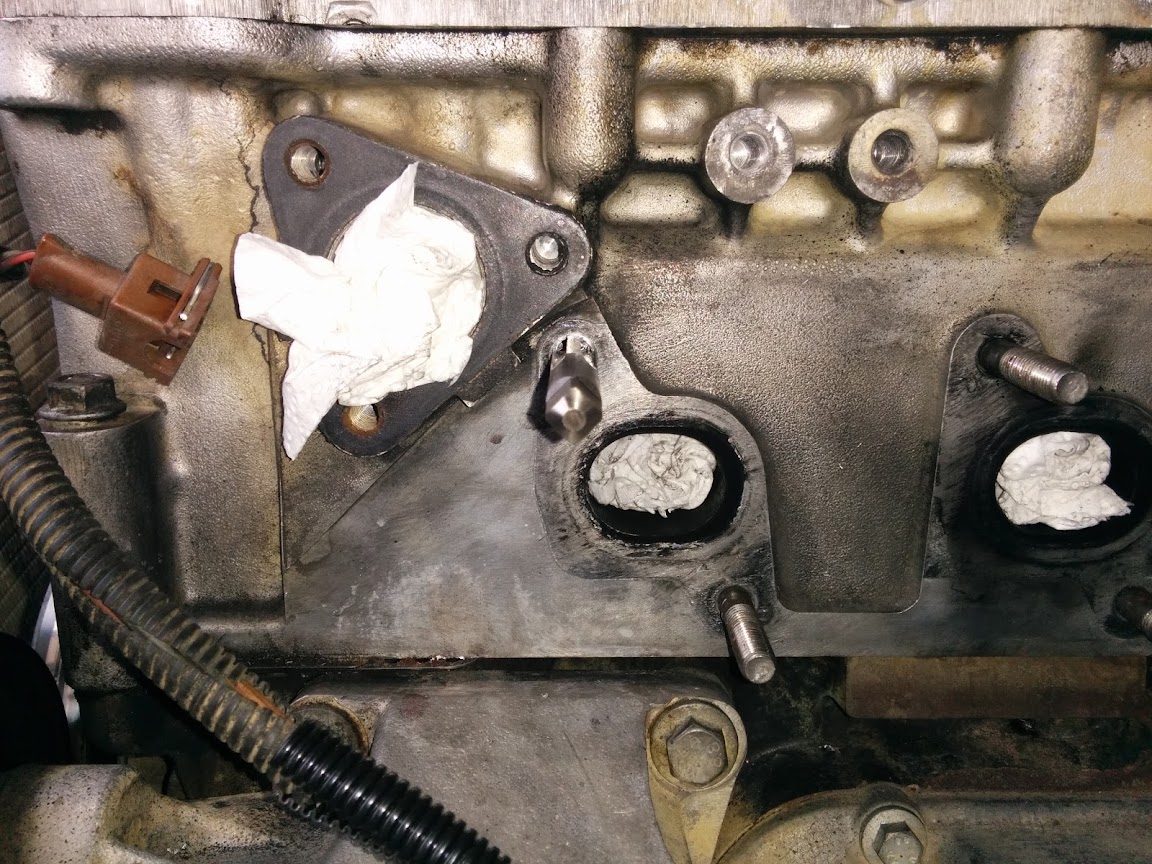

Once the bolts are out (they might put up a good fight, one of mine was BFH'd the whole way out!), disconnect the ABS sensor from the loom and feed it through the hole on the axle tube:

Now comes the hard part, you have to break the hub off the axle, if like mine yours has been on for 14 years it will be well and truly welded in place.

You can get a large punch through the ABS sensor wire hole and belt it against the hub from the rear:

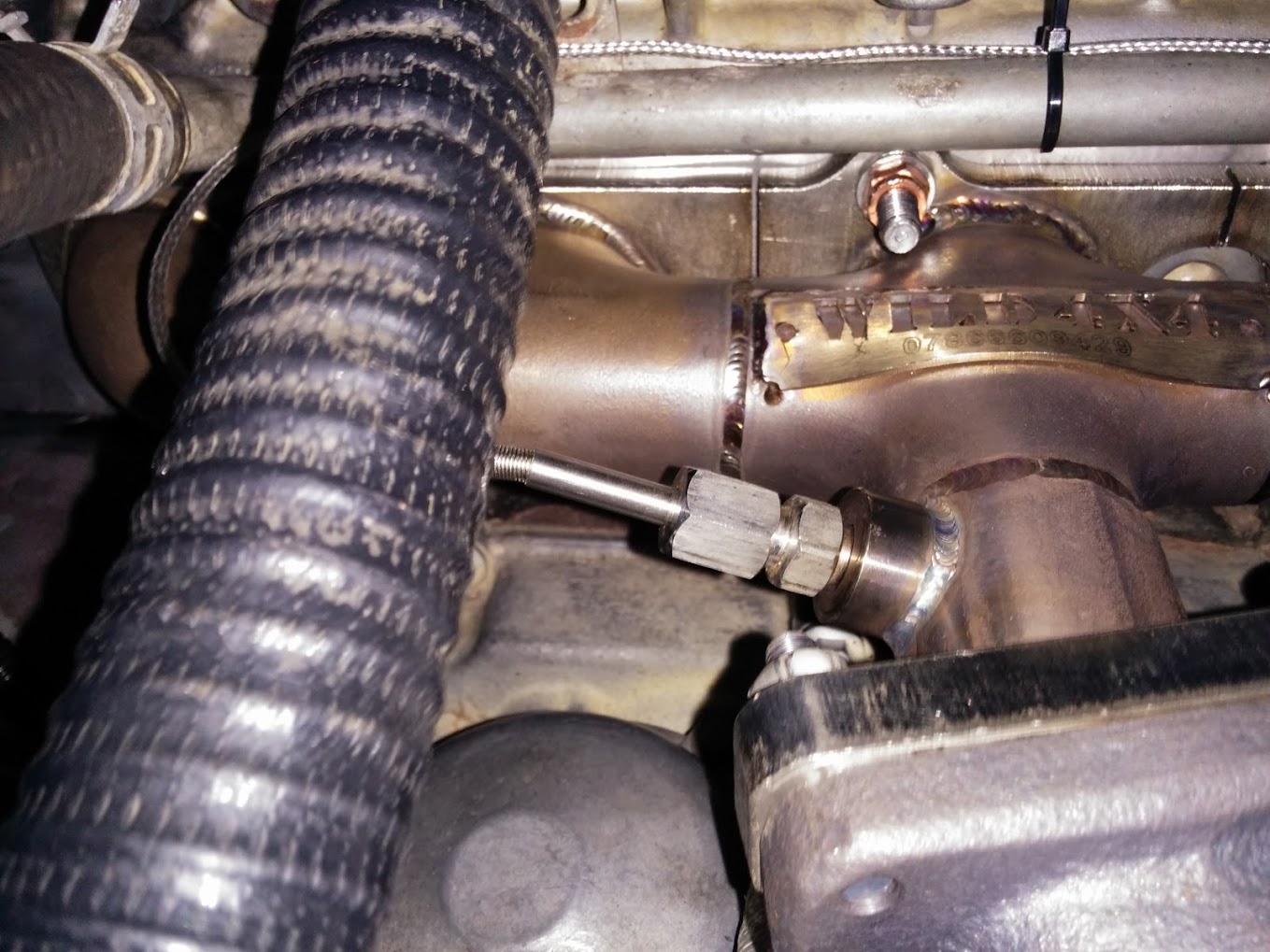

Or if you have access to one, you can use a slide hammer with a lipped attchment to pull against the hub

The slide hammer is by far the fastest method, you just move it around the circumference of the hub front whilst hammering to slowly ease the rear of the hub assembly out of the axle tube. Another method is to hammer a sharp drift into the joint - this can be messy and do damage to the mating faces.

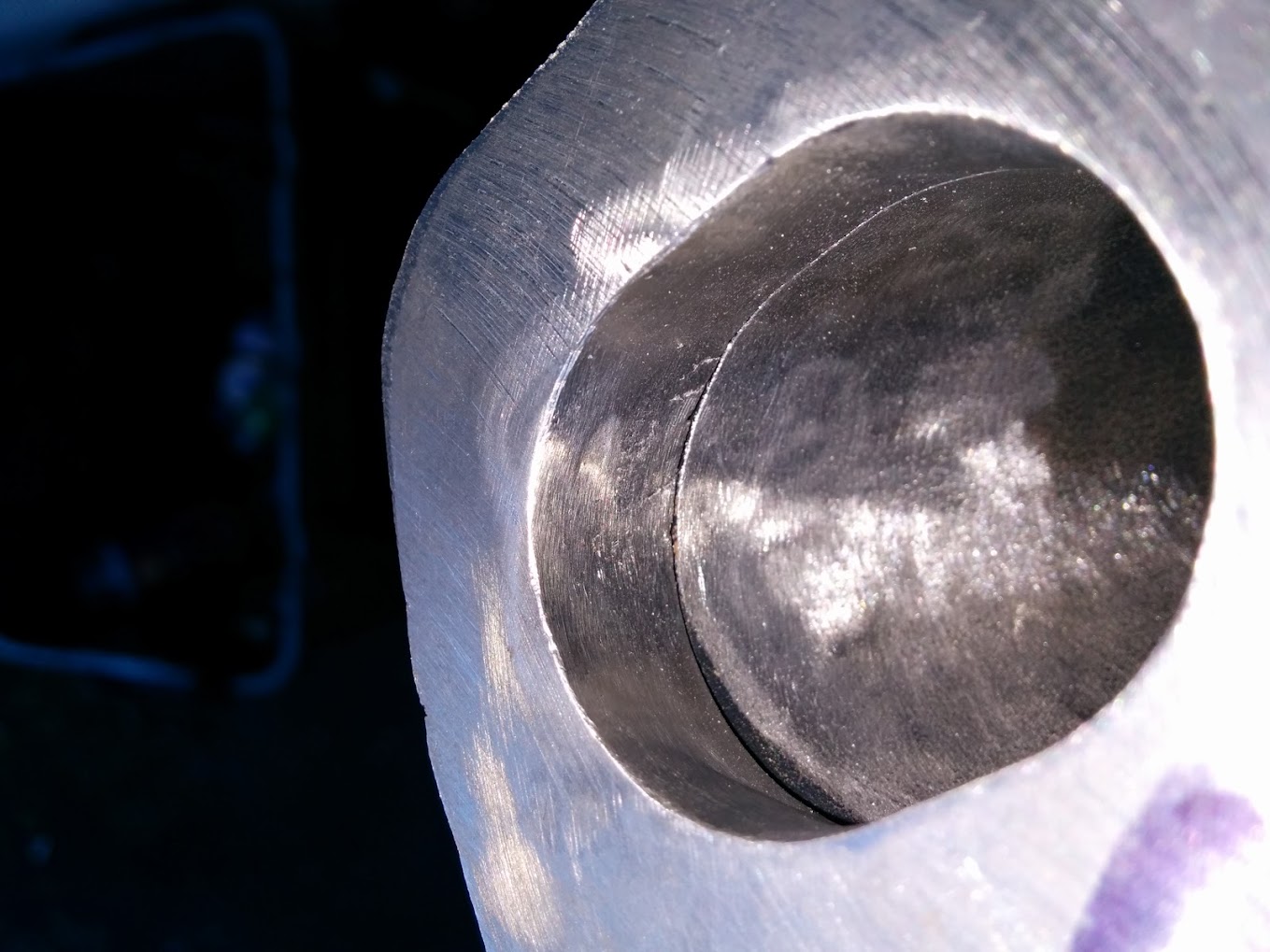

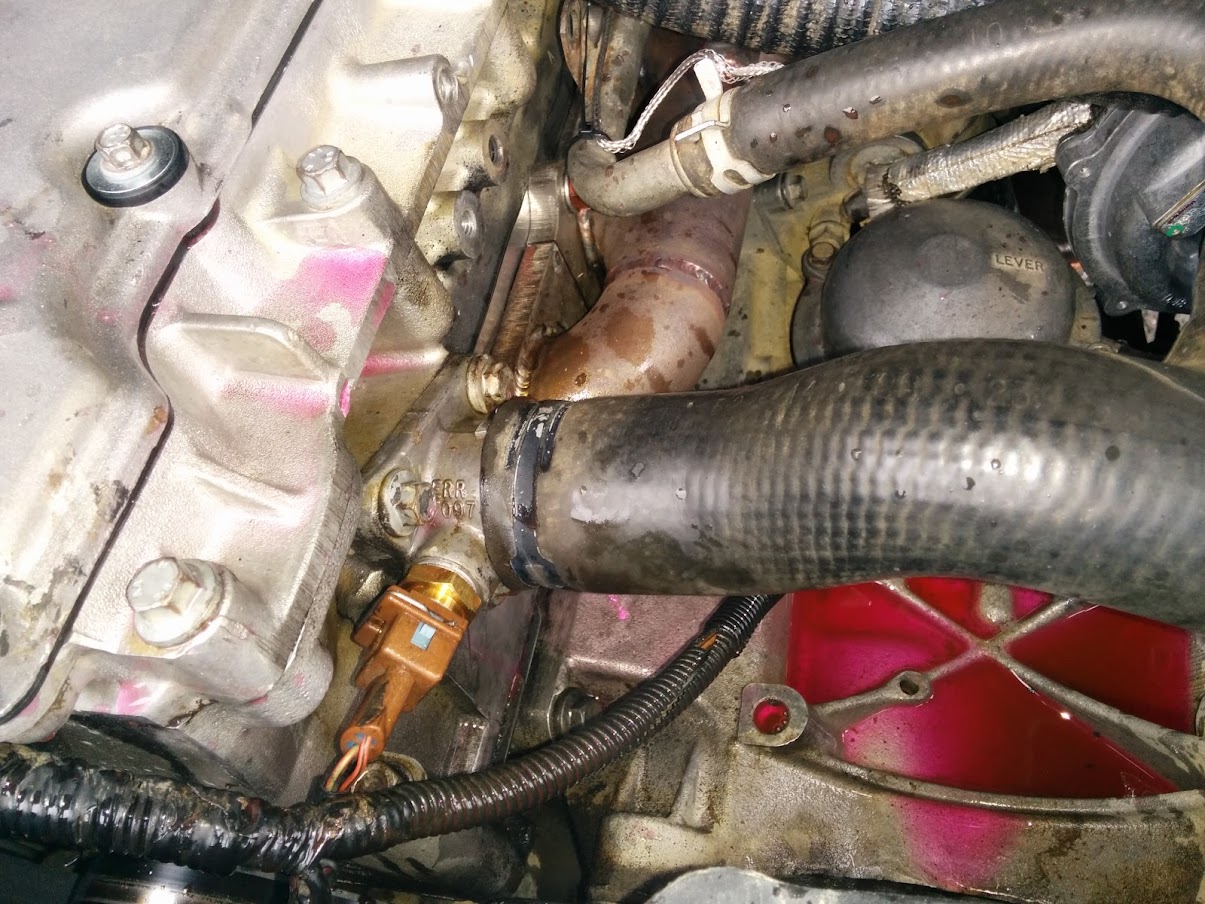

Once the hub is cracked off and levered out with a pry bar, you can extract the entire hub and half shaft from the tube. You can clearly see where mine has been leaking due to a thick rime of corrosion over the sealing o-ring

And the corresponding corrosion on the tube

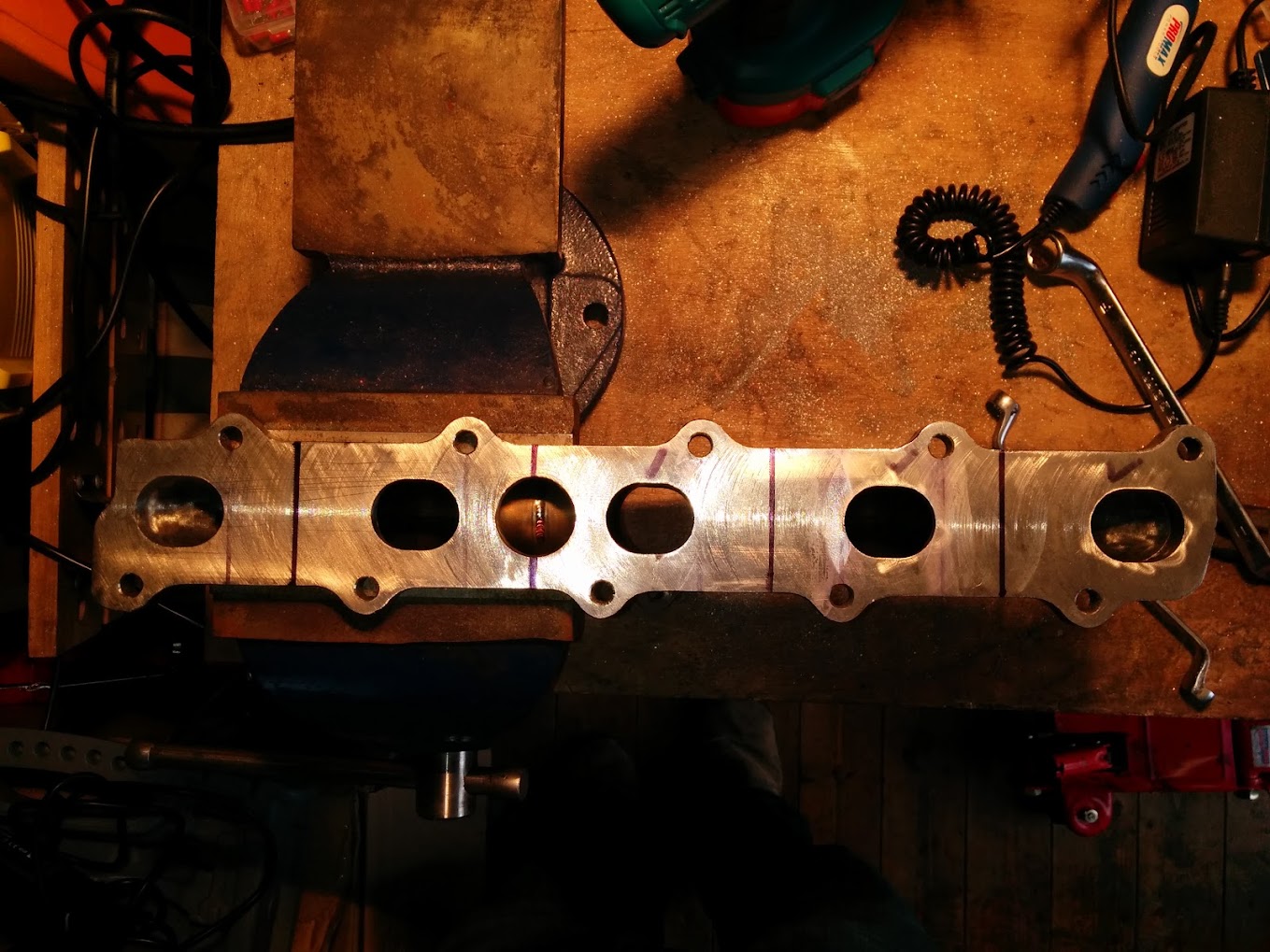

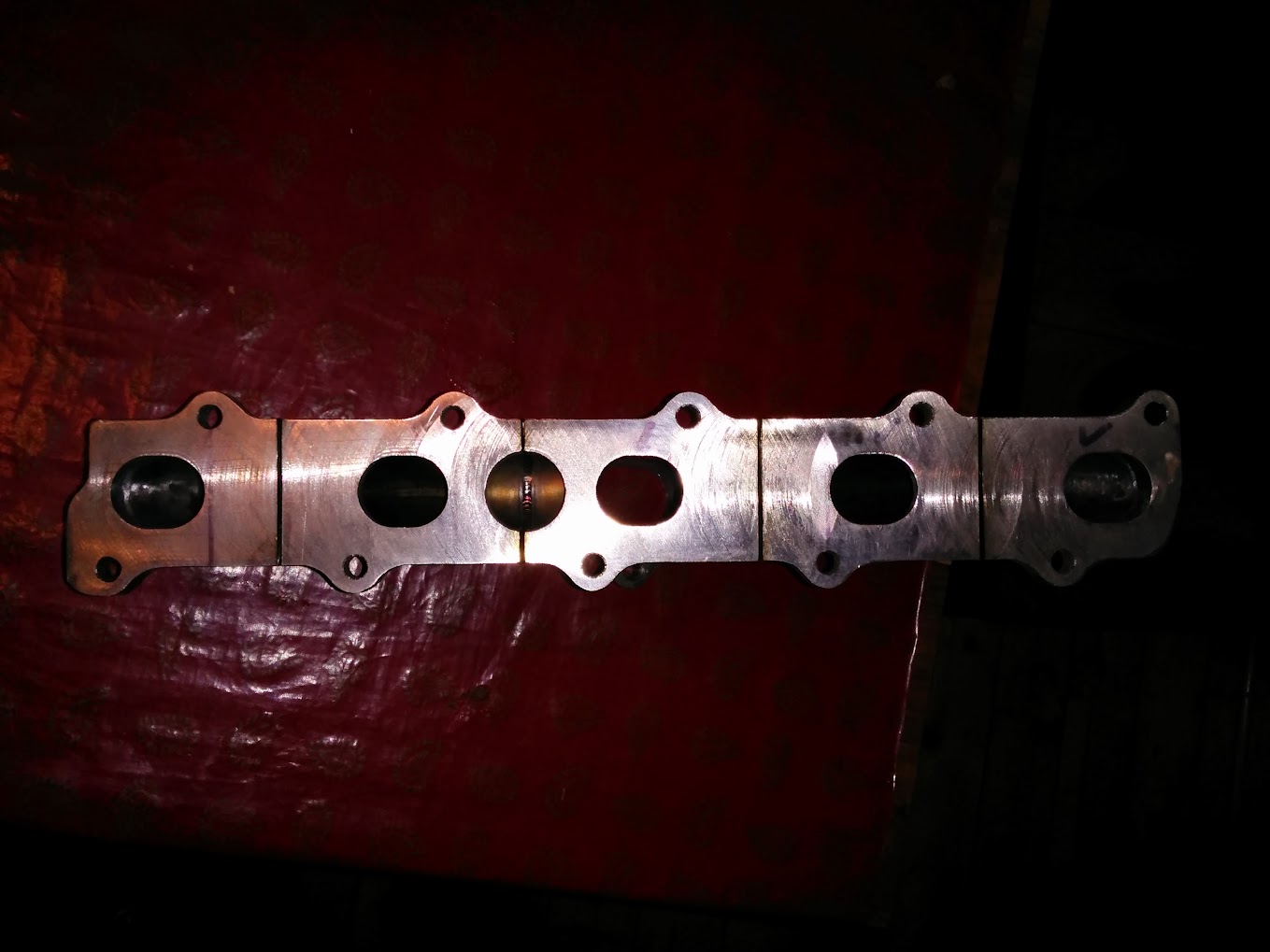

Set to the corrosion with appropriate tools to clean it off, I used a wire brush, small screwdriver, kitchen roll, and some scotchbrite. You can see where some of the axle tube has bubbled, I used a small wire wheel on a dremel to polish this down

Again after removing the old oil seal (o-ring) you can see rust and crap in the channel for it on the hub - I used the same dremel attachment to clean this up.

Once the axle tube was cleaned up I slathered the inner mating areas with lithium grease to hopefully avoid another crud build up, and to lubricate the hub/o-ring refit. I also applied copper slip to where the hub would mate up

Same deal on the hub - the bearing is in great shape after 120K miles!

Reassembly is the reverse of removal!

Before refitting the brake disk clean everything off so you'll easily spot if it continue to leak, a new hub may be required if this is the case. Also be sure to check the axle oil level!