b3nc123

Active Member

- Posts

- 227

- Location

- Derbyshire

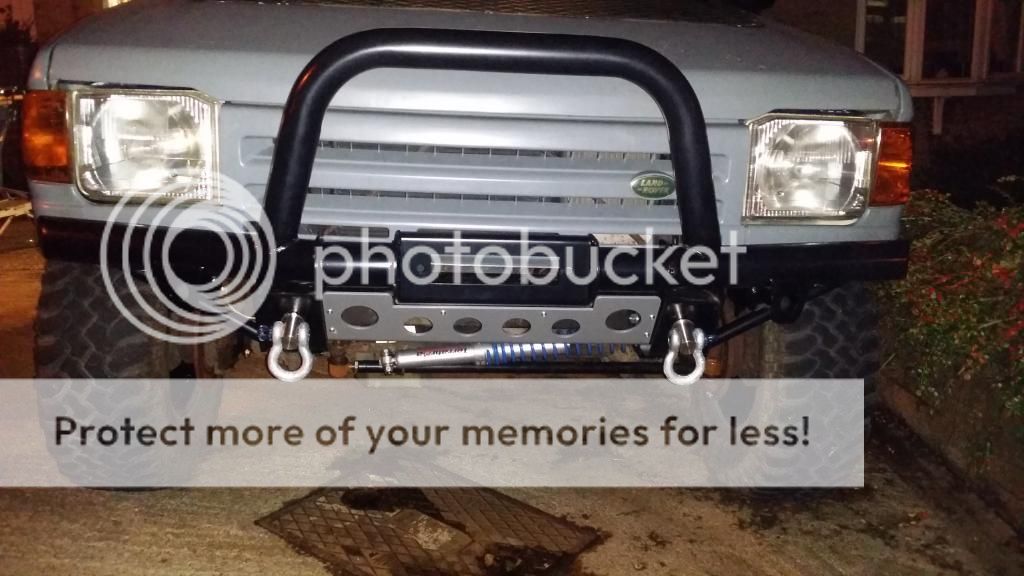

So its been a while since i last updated my project thread http://www.landyzone.co.uk/lz/f8/project-big-blue-208729.html. But i decided to start a new one seeing as the car isn't actually blue anymore.

Just wanted bring people that were interested in the last thread upto speed.

After using the Landy as it was for the remaining months it had left on the MOT it came to a few weeks before when i asked a mate who's a tester to have a quick look over it and see what would need doing. The main points that were picked up on were the side repeaters going like stink because i had removed the ones out of the rear bumper, the headlights needed adjusting and the rusty sills.

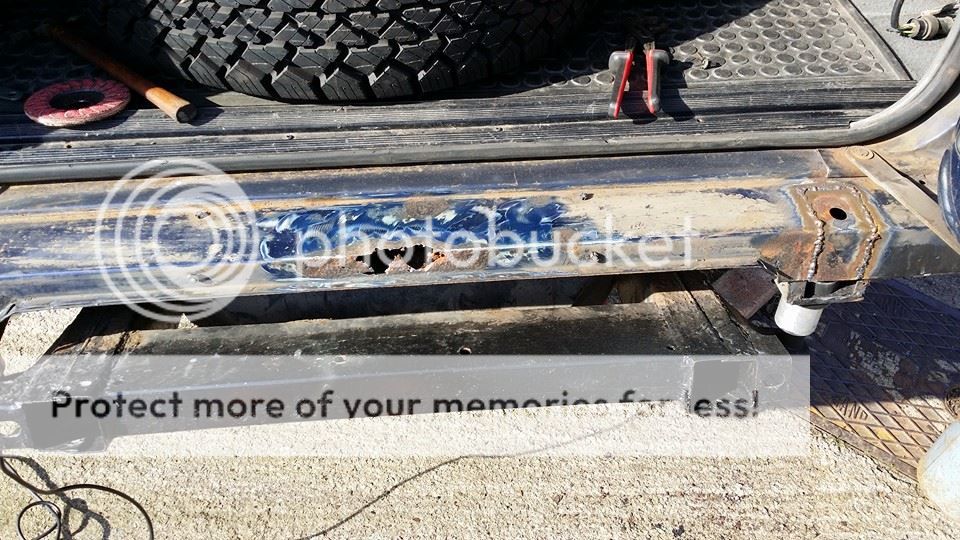

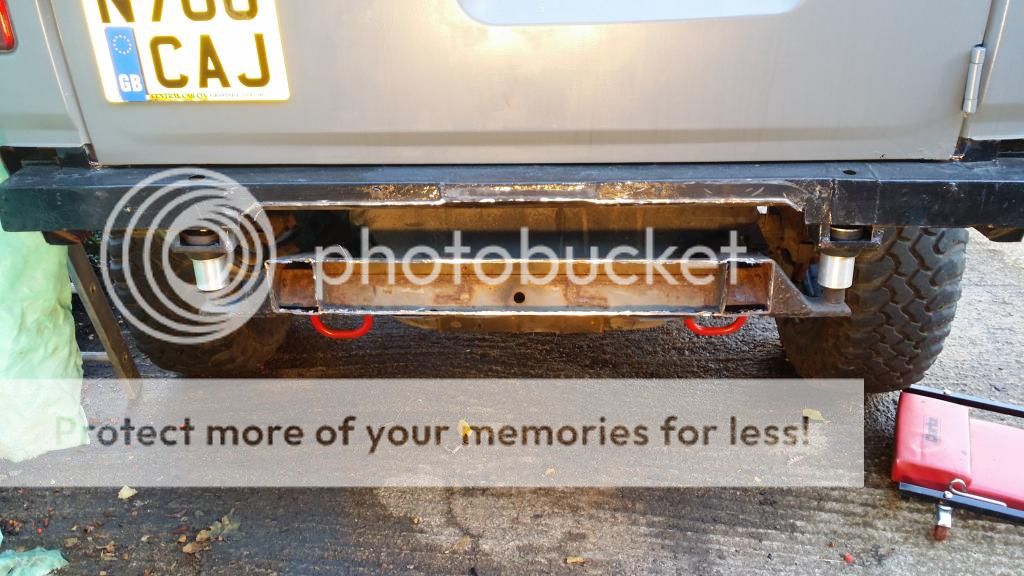

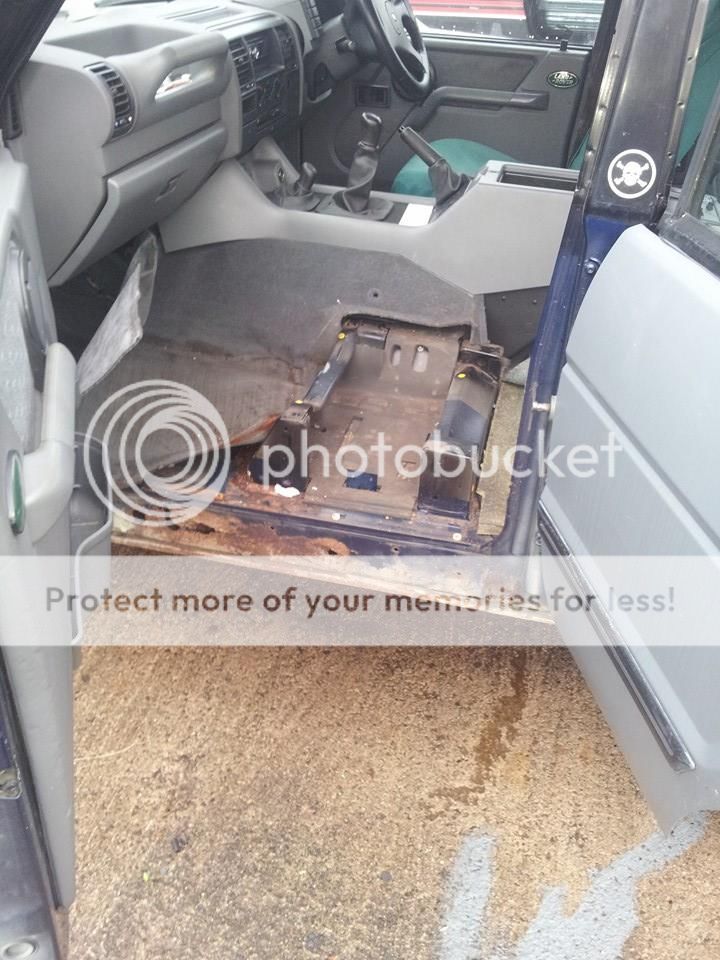

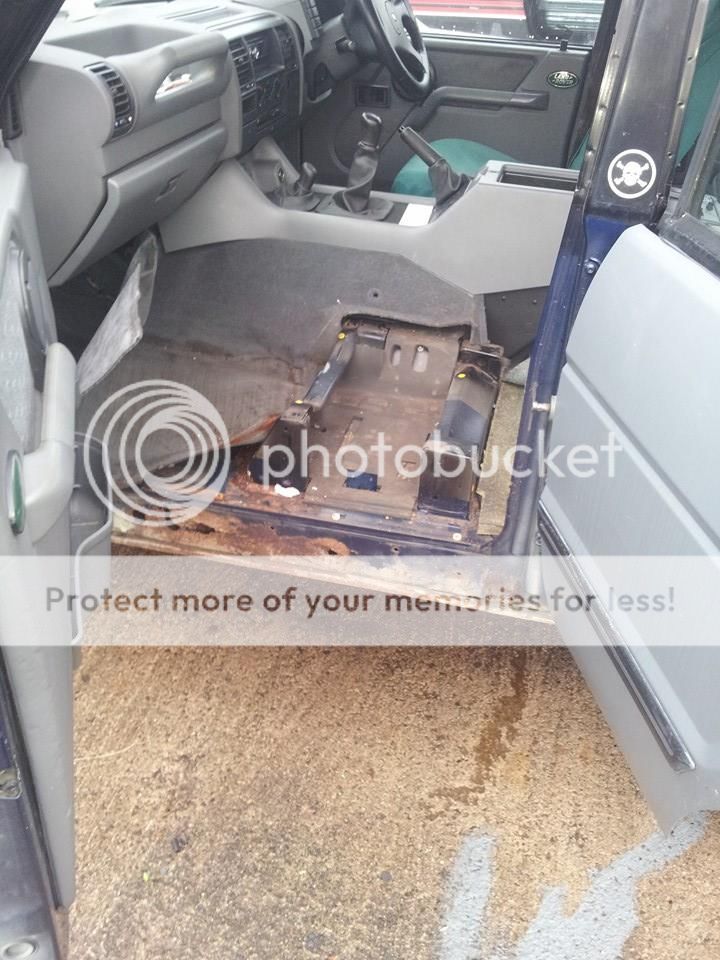

After fixing the first two i had a look at the sills, taking off the plastic cover revealed a couple of little holes.

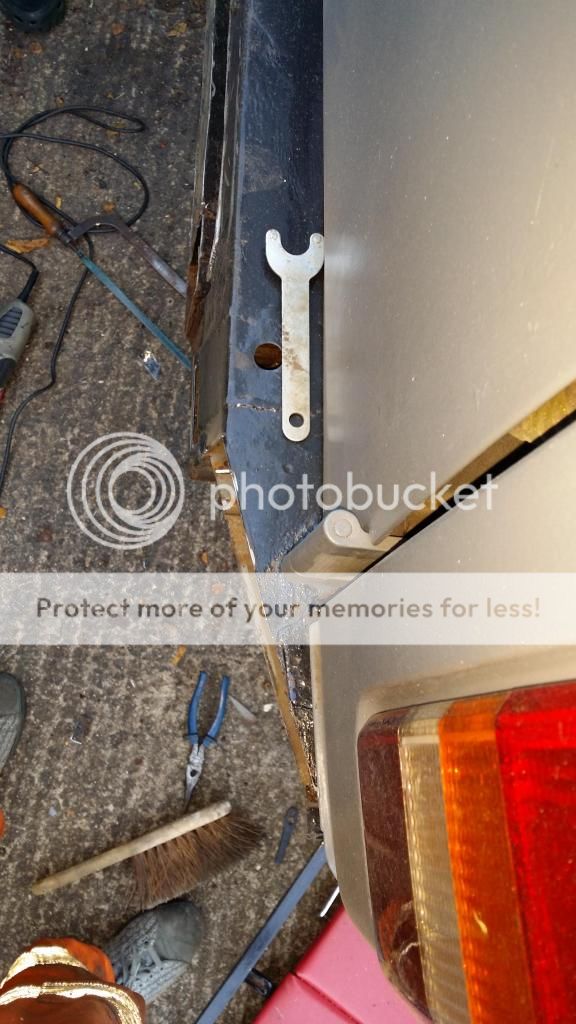

On further inspection it turned out the previous owner had done a 'quick fix' and decided to silicone a strip of metal over the original none existent sill on both sides before covering the whole lot in underseal. So out came the angle grinder and, starting with the nearside...

After seeing how soaking wet the spongy sound proofing was i wasn't surprised a couple more holes appeared in the foot wells.

I then set about about patching up the floor before tackling the sills.

The weldings not the prettiest in places but its slowly getting better.

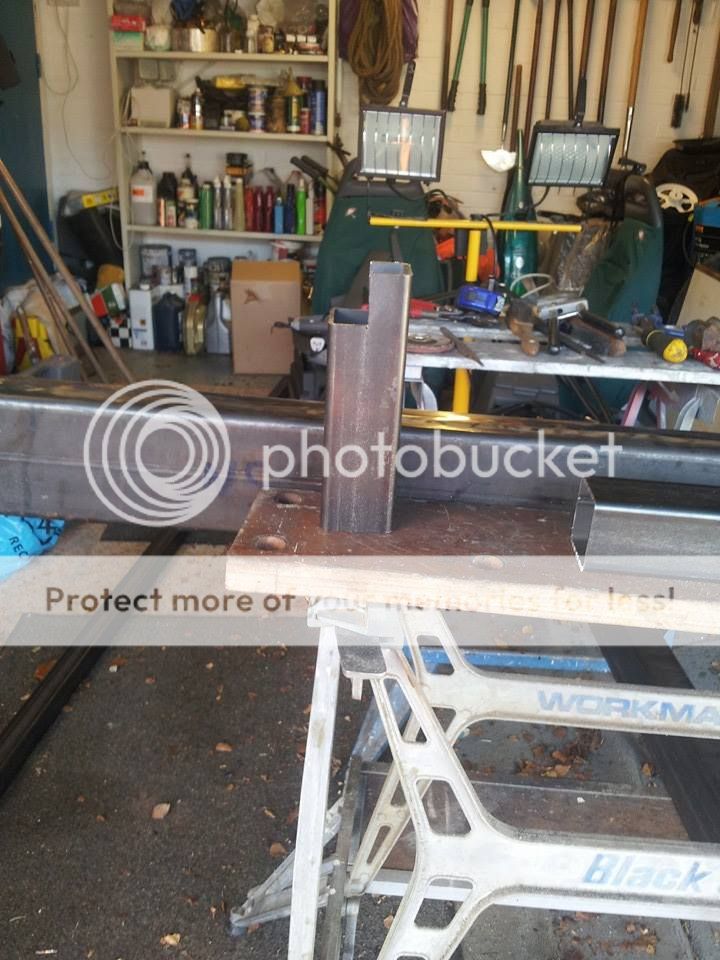

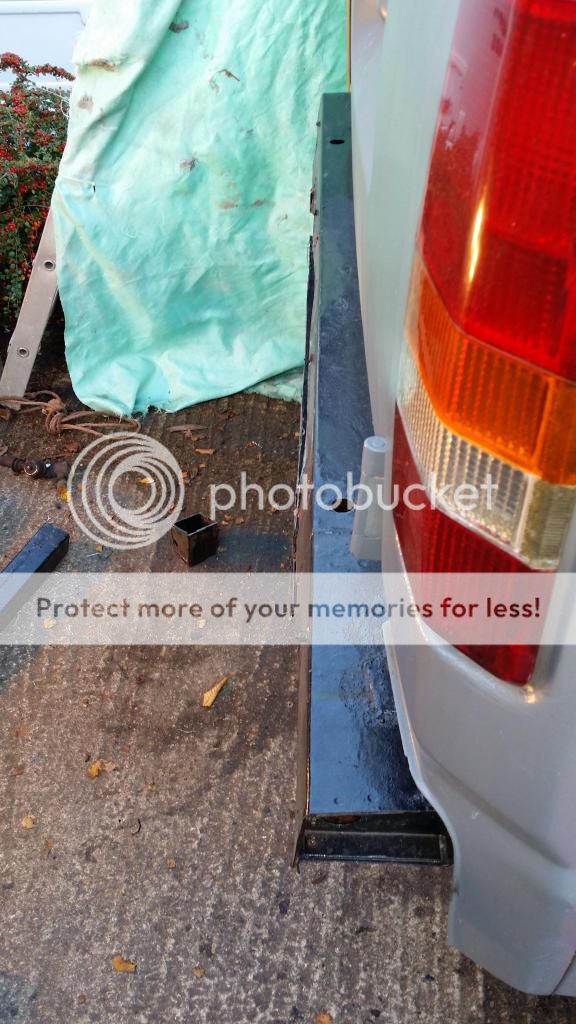

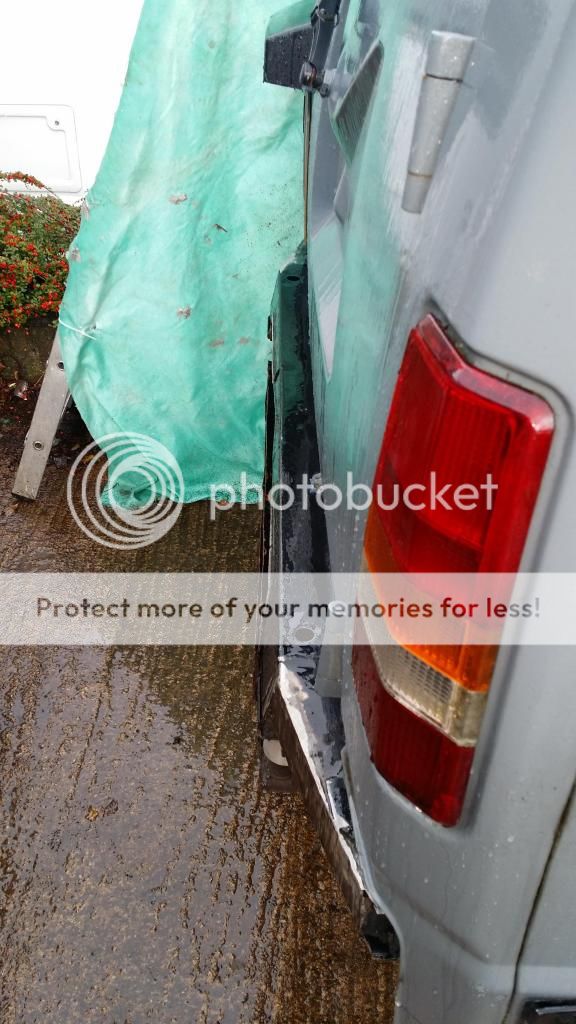

After that it was time to tackle make the sill replacements.

Just wanted bring people that were interested in the last thread upto speed.

After using the Landy as it was for the remaining months it had left on the MOT it came to a few weeks before when i asked a mate who's a tester to have a quick look over it and see what would need doing. The main points that were picked up on were the side repeaters going like stink because i had removed the ones out of the rear bumper, the headlights needed adjusting and the rusty sills.

After fixing the first two i had a look at the sills, taking off the plastic cover revealed a couple of little holes.

On further inspection it turned out the previous owner had done a 'quick fix' and decided to silicone a strip of metal over the original none existent sill on both sides before covering the whole lot in underseal. So out came the angle grinder and, starting with the nearside...

After seeing how soaking wet the spongy sound proofing was i wasn't surprised a couple more holes appeared in the foot wells.

I then set about about patching up the floor before tackling the sills.

The weldings not the prettiest in places but its slowly getting better.

After that it was time to tackle make the sill replacements.