Back in July my Disco Td5 started misfiring & cutting out, not in the classic oil in loom way, but rather massively. Nanocom would show a scramble of the following fault codes:

FAULT 27-01 injector 1 peak charge long (CURRENT)

FAULT 27-02 injector 2 peak charge long (CURRENT)

FAULT 27-03 injector 3 peak charge long (CURRENT)

FAULT 27-04 injector 4 peak charge long (CURRENT)

FAULT 27-05 injector 5 peak charge long (CURRENT)

FAULT 28-01 injector 1 peak charge short (CURRENT)

FAULT 28-02 injector 2 peak charge short (CURRENT)

FAULT 28-03 injector 3 peak charge short (CURRENT)

FAULT 28-04 injector 4 peak charge short (CURRENT)

FAULT 28-05 injector 5 peak charge short (CURRENT)

FAULT 31-01 injector 1 open circuit (CURRENT)

FAULT 31-02 injector 2 open circuit (CURRENT)

FAULT 31-03 injector 3 open circuit (CURRENT)

FAULT 31-04 injector 4 open circuit (CURRENT)

FAULT 31-05 injector 5 open circuit (CURRENT)

Engine had been thoroughly maintained, injector harness replaced not long before and absolutely no traces of oil in wiring as well as critical connectors including the red plug. Checked continuity between each individual injector connector & the respective pin in the red plug. Checked ECU grounding, battery voltage, fuses, relays, etc. everything even remotely associated with the ECU was verified and found ok. Replaced CKP sensor, fuel pump, and controlled regulated fuel pressure was right (replaced FPR last year).

The cutting out gradually worsened over a 2-month period to the point at which the engine would stop altogether (without any previous misfiring) under high load and the check engine light showed up.

The fault code in this scenario was always:

FAULT 28-07 topside switch failed pre injection (CURRENT)

This new evidence pointed the finger towards the ECU so started looking for a replacement. Won a used one on fleabay and a few long weeks later fetched it from customs, plugged it in, programmed injector codes, learned security code and fired up the engine. Warmed engine up a bit and came down the driveway, but as soon as I let weight on the throttle the engine cut out immediately, would not take any load at all, over and over. Turned out the 'new' ECU was twice as buggered as mine! Could even see traces of dry oil around the four tiny ports on the back (eBlag dispute ongoing). Back to the start and another few weeks before I located a 'tried, tested & guaranteed' ECU off a breaker yard.

At this point the Disco was barely drivable so took advantage of the sit time and did several low key but time consuming jobs in preparation for a future remap. Pulled out and cleaned intercooler, radiator, hoses, etc. Blanked off EGR, modified exhaust manifold, changed out studs, replaced oil cooler, oil centrifuge & oil filter housing gaskets. Replaced suspicious clips, secured cables, installed silicone hoses; cleaned plugs, changed out engine mounts, springs, shocks, track rod, link rod, etc.

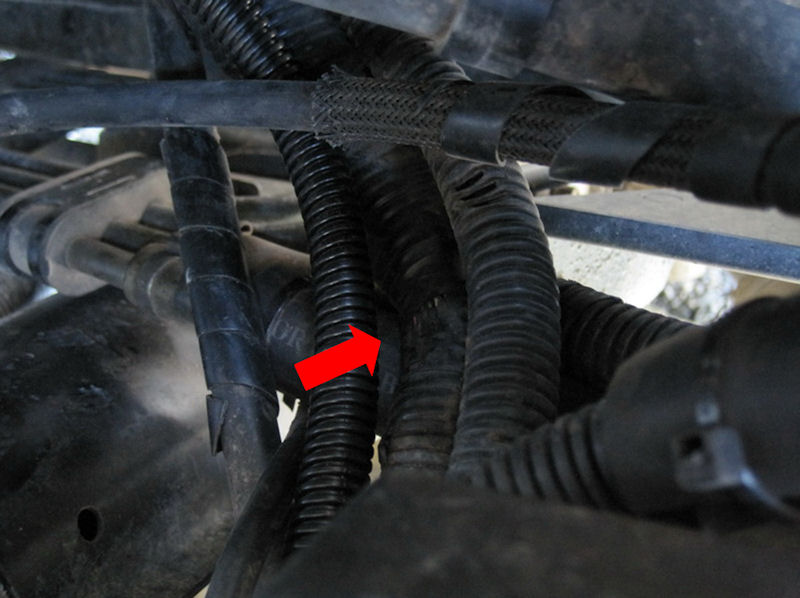

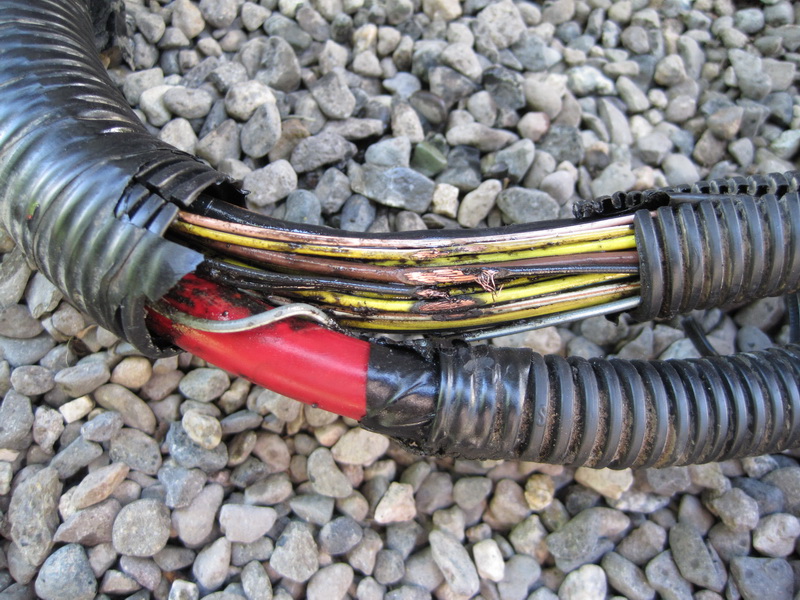

It was during this process that I noticed that the section of engine harness conduit going from the back of the battery compartment to the engine, had been rubbing against the ACE lines (right below the coolant reservoir), and it was literally mounted on top. More concerned about a potential leak development in the upper ACE line, wrapped it with a slit piece of hi temp rubber hose (engine harness getting moved around in the process).

Anticipating a frustrating journey drove the Disco to town for a wheel alignment session but experienced no misfiring or cutting at all. Drove it around lightly for another 5 days, still good! Took the highway and got rough with her this time but still not a single miss. Though uneasy about not knowing what the problem truly was or how it was involuntarily fixed, declared the Disco once again healthy.

Soon came a planned long weekend family trip and decided to take the now well behaved Disco. Drove about 70 km on a paved road and took a shortcut through a rough mountain pass with plenty of corrugated dirt sections, deep holes and rock outcroppings. About 30' into it the engine started cutting out again. It became progressively worse & to the point where even a small bump would cut the engine out! The difference this time was that the misfiring and cutting out were not random but in response to road surface features! Turned around & managed to get home giving the starter motor the day of its life, as well as infuriating the wife & kids

With the ECU still weeks away and evidence that the problem could be laying somewhere else (although ECU was still topsiding under heavy load and continuity was re-checked good between ECU and each injector in static conditions), resolved to try out a different approach... Disconnected the plug going into the engine (C0171) and peeled off enough tape on the conduit going back to the ECU as to be able to freely pull a good 8 inches on the 7 wire bundle coming from the said plug. Cut the 7 cables about 6 inches from the injector harness connector (right before the conduit dives down through inlet manifold), ran heat shrink tubing, soldered 7 new wires, heat shrank, ran into 1/4" slit conduit, and taped & zip tied in place.

Then ran the conduit and the 7 cables inside down through the inlet manifold and followed the engine harness path all the way to the plastic receptacle where the ECU is housed. Pulled off the cables corresponding to pins 1, 22, 23, 24, 25, 26 & 27 on the red plug and cut, soldered, etc.

Fired her up and never again has it missed a beat let alone cut out! Despite this, have a new engine harness on order as I have my doubts about the long term integrity of the soldered connections.

Here's where the engine harness had been chaffing against the ACE lines & suspect the conductors had been damaged:

It's a low point therefore if any oil or dirt built up between partially peeled conductors then that could explain the ECUs topside switch failures (partial shorting between conductors at higher loads) and why they have not come back since the bypass surgery, though always keep the spare ECU handy just in case there was permanent damage inflicted to the ECU and it eventually decides to give up.

Put together the following diagram as to help me out in the process:

FAULT 27-01 injector 1 peak charge long (CURRENT)

FAULT 27-02 injector 2 peak charge long (CURRENT)

FAULT 27-03 injector 3 peak charge long (CURRENT)

FAULT 27-04 injector 4 peak charge long (CURRENT)

FAULT 27-05 injector 5 peak charge long (CURRENT)

FAULT 28-01 injector 1 peak charge short (CURRENT)

FAULT 28-02 injector 2 peak charge short (CURRENT)

FAULT 28-03 injector 3 peak charge short (CURRENT)

FAULT 28-04 injector 4 peak charge short (CURRENT)

FAULT 28-05 injector 5 peak charge short (CURRENT)

FAULT 31-01 injector 1 open circuit (CURRENT)

FAULT 31-02 injector 2 open circuit (CURRENT)

FAULT 31-03 injector 3 open circuit (CURRENT)

FAULT 31-04 injector 4 open circuit (CURRENT)

FAULT 31-05 injector 5 open circuit (CURRENT)

Engine had been thoroughly maintained, injector harness replaced not long before and absolutely no traces of oil in wiring as well as critical connectors including the red plug. Checked continuity between each individual injector connector & the respective pin in the red plug. Checked ECU grounding, battery voltage, fuses, relays, etc. everything even remotely associated with the ECU was verified and found ok. Replaced CKP sensor, fuel pump, and controlled regulated fuel pressure was right (replaced FPR last year).

The cutting out gradually worsened over a 2-month period to the point at which the engine would stop altogether (without any previous misfiring) under high load and the check engine light showed up.

The fault code in this scenario was always:

FAULT 28-07 topside switch failed pre injection (CURRENT)

This new evidence pointed the finger towards the ECU so started looking for a replacement. Won a used one on fleabay and a few long weeks later fetched it from customs, plugged it in, programmed injector codes, learned security code and fired up the engine. Warmed engine up a bit and came down the driveway, but as soon as I let weight on the throttle the engine cut out immediately, would not take any load at all, over and over. Turned out the 'new' ECU was twice as buggered as mine! Could even see traces of dry oil around the four tiny ports on the back (eBlag dispute ongoing). Back to the start and another few weeks before I located a 'tried, tested & guaranteed' ECU off a breaker yard.

At this point the Disco was barely drivable so took advantage of the sit time and did several low key but time consuming jobs in preparation for a future remap. Pulled out and cleaned intercooler, radiator, hoses, etc. Blanked off EGR, modified exhaust manifold, changed out studs, replaced oil cooler, oil centrifuge & oil filter housing gaskets. Replaced suspicious clips, secured cables, installed silicone hoses; cleaned plugs, changed out engine mounts, springs, shocks, track rod, link rod, etc.

It was during this process that I noticed that the section of engine harness conduit going from the back of the battery compartment to the engine, had been rubbing against the ACE lines (right below the coolant reservoir), and it was literally mounted on top. More concerned about a potential leak development in the upper ACE line, wrapped it with a slit piece of hi temp rubber hose (engine harness getting moved around in the process).

Anticipating a frustrating journey drove the Disco to town for a wheel alignment session but experienced no misfiring or cutting at all. Drove it around lightly for another 5 days, still good! Took the highway and got rough with her this time but still not a single miss. Though uneasy about not knowing what the problem truly was or how it was involuntarily fixed, declared the Disco once again healthy.

Soon came a planned long weekend family trip and decided to take the now well behaved Disco. Drove about 70 km on a paved road and took a shortcut through a rough mountain pass with plenty of corrugated dirt sections, deep holes and rock outcroppings. About 30' into it the engine started cutting out again. It became progressively worse & to the point where even a small bump would cut the engine out! The difference this time was that the misfiring and cutting out were not random but in response to road surface features! Turned around & managed to get home giving the starter motor the day of its life, as well as infuriating the wife & kids

With the ECU still weeks away and evidence that the problem could be laying somewhere else (although ECU was still topsiding under heavy load and continuity was re-checked good between ECU and each injector in static conditions), resolved to try out a different approach... Disconnected the plug going into the engine (C0171) and peeled off enough tape on the conduit going back to the ECU as to be able to freely pull a good 8 inches on the 7 wire bundle coming from the said plug. Cut the 7 cables about 6 inches from the injector harness connector (right before the conduit dives down through inlet manifold), ran heat shrink tubing, soldered 7 new wires, heat shrank, ran into 1/4" slit conduit, and taped & zip tied in place.

Then ran the conduit and the 7 cables inside down through the inlet manifold and followed the engine harness path all the way to the plastic receptacle where the ECU is housed. Pulled off the cables corresponding to pins 1, 22, 23, 24, 25, 26 & 27 on the red plug and cut, soldered, etc.

Fired her up and never again has it missed a beat let alone cut out! Despite this, have a new engine harness on order as I have my doubts about the long term integrity of the soldered connections.

Here's where the engine harness had been chaffing against the ACE lines & suspect the conductors had been damaged:

It's a low point therefore if any oil or dirt built up between partially peeled conductors then that could explain the ECUs topside switch failures (partial shorting between conductors at higher loads) and why they have not come back since the bypass surgery, though always keep the spare ECU handy just in case there was permanent damage inflicted to the ECU and it eventually decides to give up.

Put together the following diagram as to help me out in the process: