binaryfinary

New Member

- Posts

- 6

Helping a friend fix his Land Rover Freelander TD4 (54 plate - 2004).

Dodgy electrics, pointed to a bad alternator, but we also noticed the belt was slipping and bouncing around a lot, so before spending a lot of money on a new alternator, replacing the belt seemed the best option.

The job was easy up until re-fitting the belt. Some issues with the compressor belt (which was also very worn) being a tight fit, but we got there in the end.

The new aux belt however will NOT fit. When we loosened the tensioner to remove the belt, it slipped off the crank pulley very easily. Now, it isn't even approaching slack enough to fit half way over any last pulley. We've tried using the crank, the alternator and the one under the tensioner as the last pulley we slip the belt over, still inches more slack needed.

We know that we aren't suffering from the obvious common mistakes -

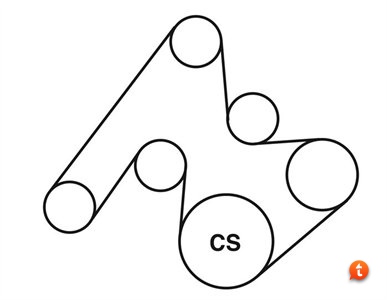

1. The routing is correct and the belt is seated correctly.

2. The belt is the right size. We even tried the old belt to make sure its wasn't a case of a bad part number, but it was the same story.

I'm guessing we've messed up something somewhere with the tensioner, and/or we're missing a common trick here. We are not morons and have seen plenty of evidence on the internet (on this forum and others) that this is a 10 minute job.

We are thinking perhaps something wrong with the tensioner. Is is adjustable? Perhaps we've adjusted it by mistake? Is there any way to mistakenly move one of the other pulleys? It seems not, but we're literally almost insane now. We've spent 7 hours trying to fit this belt, both of us have badly cut up our hands in the process and the nightmare is set to continue into another day, so any help is greatly appreciated.

Dodgy electrics, pointed to a bad alternator, but we also noticed the belt was slipping and bouncing around a lot, so before spending a lot of money on a new alternator, replacing the belt seemed the best option.

The job was easy up until re-fitting the belt. Some issues with the compressor belt (which was also very worn) being a tight fit, but we got there in the end.

The new aux belt however will NOT fit. When we loosened the tensioner to remove the belt, it slipped off the crank pulley very easily. Now, it isn't even approaching slack enough to fit half way over any last pulley. We've tried using the crank, the alternator and the one under the tensioner as the last pulley we slip the belt over, still inches more slack needed.

We know that we aren't suffering from the obvious common mistakes -

1. The routing is correct and the belt is seated correctly.

2. The belt is the right size. We even tried the old belt to make sure its wasn't a case of a bad part number, but it was the same story.

I'm guessing we've messed up something somewhere with the tensioner, and/or we're missing a common trick here. We are not morons and have seen plenty of evidence on the internet (on this forum and others) that this is a 10 minute job.

We are thinking perhaps something wrong with the tensioner. Is is adjustable? Perhaps we've adjusted it by mistake? Is there any way to mistakenly move one of the other pulleys? It seems not, but we're literally almost insane now. We've spent 7 hours trying to fit this belt, both of us have badly cut up our hands in the process and the nightmare is set to continue into another day, so any help is greatly appreciated.