LincolnSteve

Well-Known Member

- Posts

- 1,224

- Location

- Lincoln

Bugger.LOL, Not quite. I made an offer of £13 and it was accepted, plus it is a more expensive model with better filters.

Bugger.LOL, Not quite. I made an offer of £13 and it was accepted, plus it is a more expensive model with better filters.

Thanks for that. I'm very impressed with your progress as well. I didn't realise James and Aztech were one and the same. It's a small world.Chassis is looking good Steve.

Aztech engineering is James Martin on here, Sure he would come highly recommended by most on here.

Thanks for the kind comments. You should see the garage now. With both axles in bits in there you can't move. I could now do with 4 times the space.wandered in from the series forum, great read and excellent work on the chassis, I too have garage envy

Ok. I'll get on it.^^^

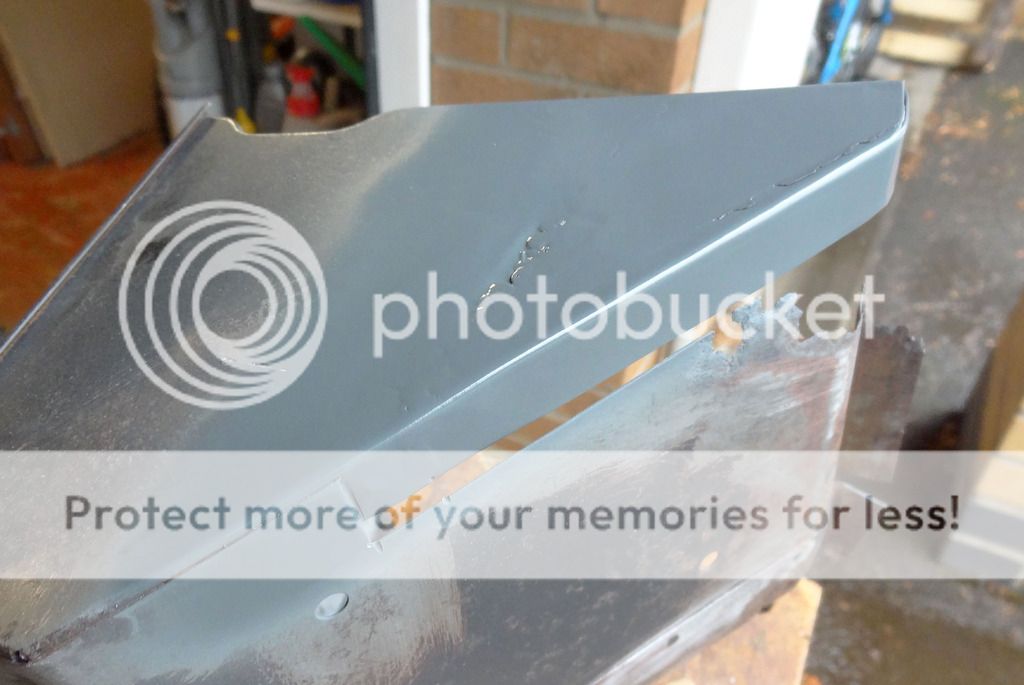

Don't believe you! Photographic evidence is required to back up such claims!

.

.

thats poor ,i cant say have had any like thatMy new Britpart swivel kits arrived from Craddocks. I opened up the tatty box to find the Railko bush box has been ripped open and just left like it. The main problem though is that both swivels are rusty. Small pin prick dots of rust all over, some pitted areas and best of all a rusty finger print. They wouldn't last five minutes before they were leaking and ruining the new seals. I know you hear horror stories about the dreaded blue boxes but I didn't think they would be this bad!

I know. I'm hoping it's just a Friday afternoon set and I can get decent replacements. I've spoken to Craddocks on Saturday and emailed photos. No word yet.thats poor ,i cant say have had any like that

Welcome To LandyZone, the Land Rover Forums!

Here at LandyZone we have plenty of very knowledgable members so if you have any questions about your Land Rover or just want to connect with other Landy owners, you're in the right place.

Registering is free and easy just click here, we hope to see you on the forums soon!