Next was a case of tidying things up bolting things back together setting up timing and so on. And it appears to run like a gem - took it for a good run (fully loaded with all our rally gear) and pulls much better than the old engine - it has probably been on the way out for a while. Only a slight leak around the oil cooler sandwich plate to address. So we are on for re-launching the rally on the 10th of September 2012. Woop!

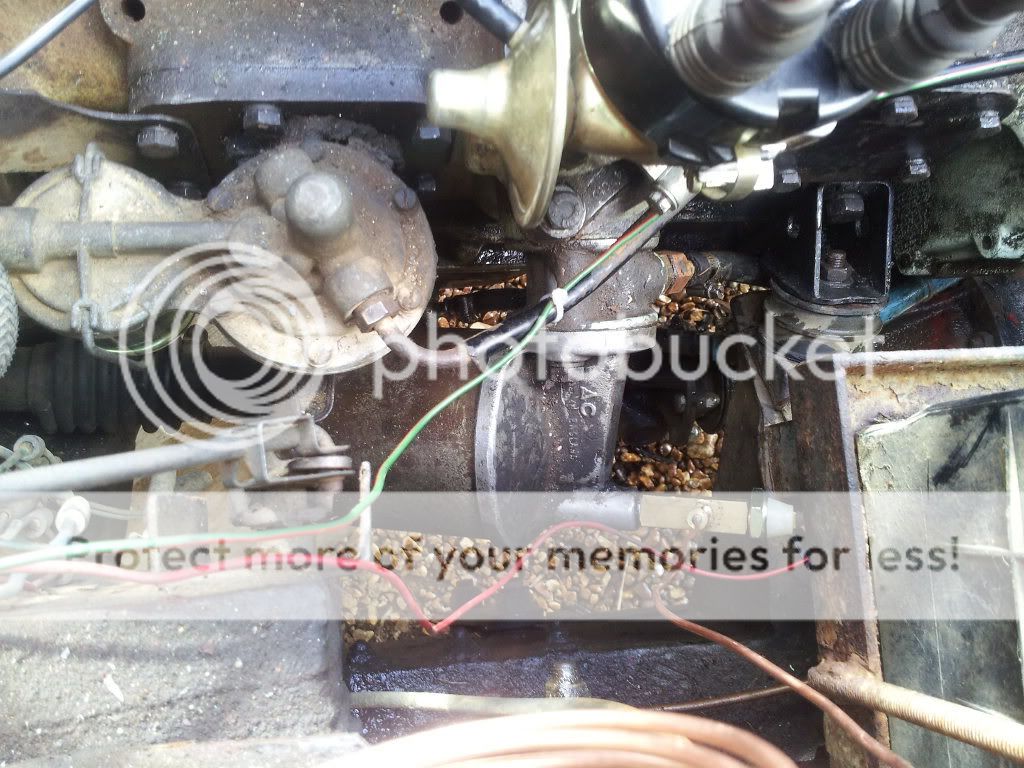

Being slightly paranoid about oil pressure now decided it would be a good idea to fit an oil pressure gauge. Standard t-piece fitting:

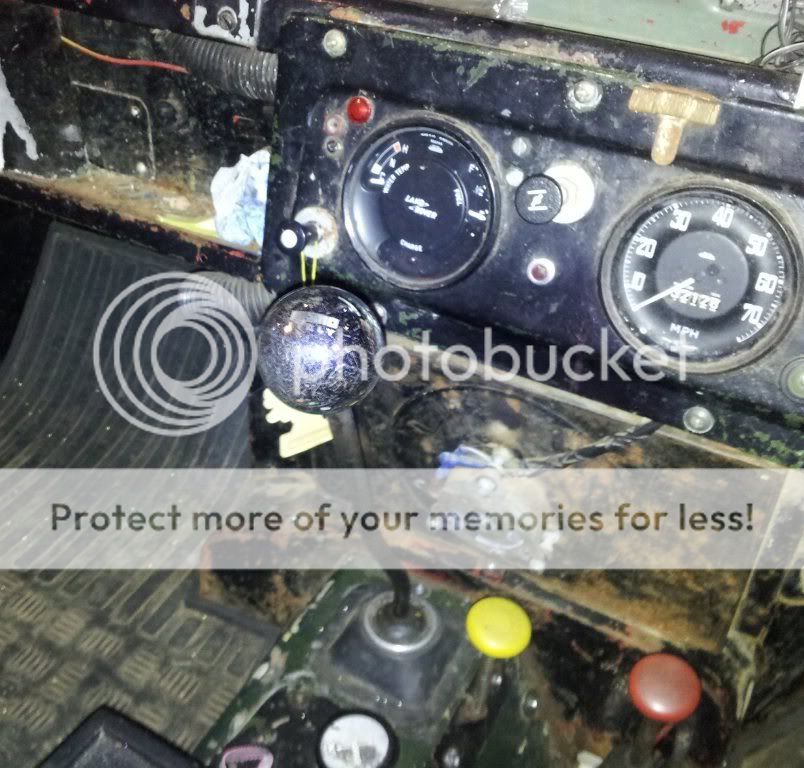

And the gauge. Doesn't look too out of place in my opinion and gives the co-pilot something to look at. Rivet counters will hate my interior anyway so, oh well. Runs at about 20psi on idle and between 45-60 on running which seems about right to me.

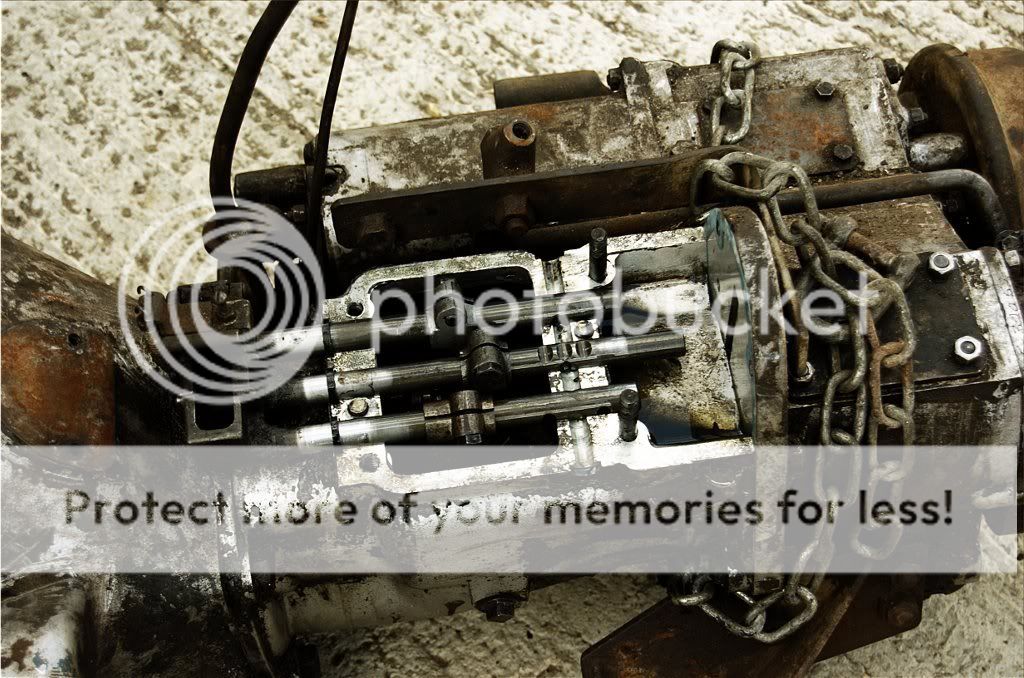

Next thing to address: Leaky top plate on the top of the gearbox. On these, accessible by the cab there is an inspection plate on the casing. Now...the casing for the box we have has the filler type on the top...but it leaks (a lot) through the filler cap. Perhaps because I have different internals to which the casing is designed for. Now we could have fitted the box with what should be on there - the plain blanking plate without the filler cap but that would mean filling the gearbox from underneath again which I am not terribly keen on - I like the idea of being able to fill easily from the cab. What we needed is a different filler whilst keeping it sealed but also breathing.

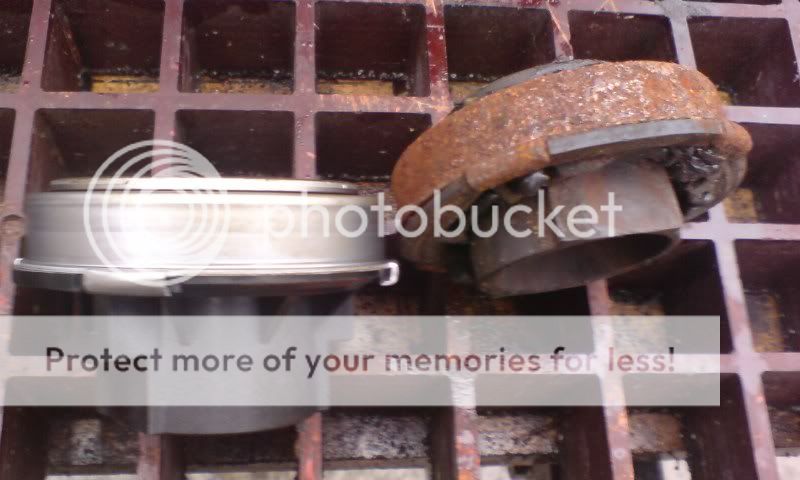

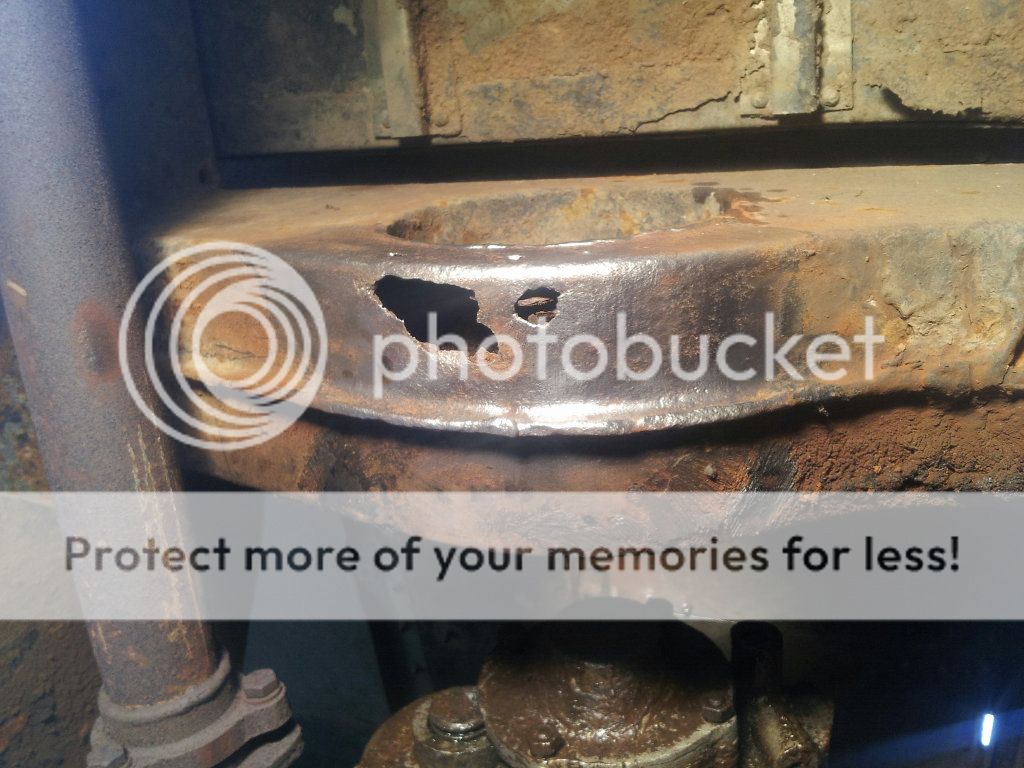

So we got the standard blanking plate (which has a breather built in). Drilled a hole in it. Then welded a bit of rod to it for a filler extension neck. Of course we needed a plug of some description to stop it coming out the top of this neck:

See where I am going with this? Posted Image You make do with the bits you can find around the garden, so a spark plug which we happen to have the correct tap for was perfect. Spark plug also works quite nicely has it has the sealing washer. So what you are seeing in the pic (from left to right) is the standard filler cap, drilled out, with a bit of tube welded on, with a spark plug screwed in it (!)

Before (standard top filler type arrangement for this casing):

After...it looks a bit weird but it works!

And with the spark-plug-filler-cap-thing in place. Of course for the spark plug to work, we had to drill out the insides of it and lob off the bits we don't need. This leaves a hole down the middle of the spark plug so got a piece of solid tube, placed in the hole and welded in place. Ta-da - extended-filler-neck-but-keeping-a-sealed-gearbox-top-plate-thing (again, those that prefer a more genuine Land Rover will hate me for doing things like this but I will not apologise!):

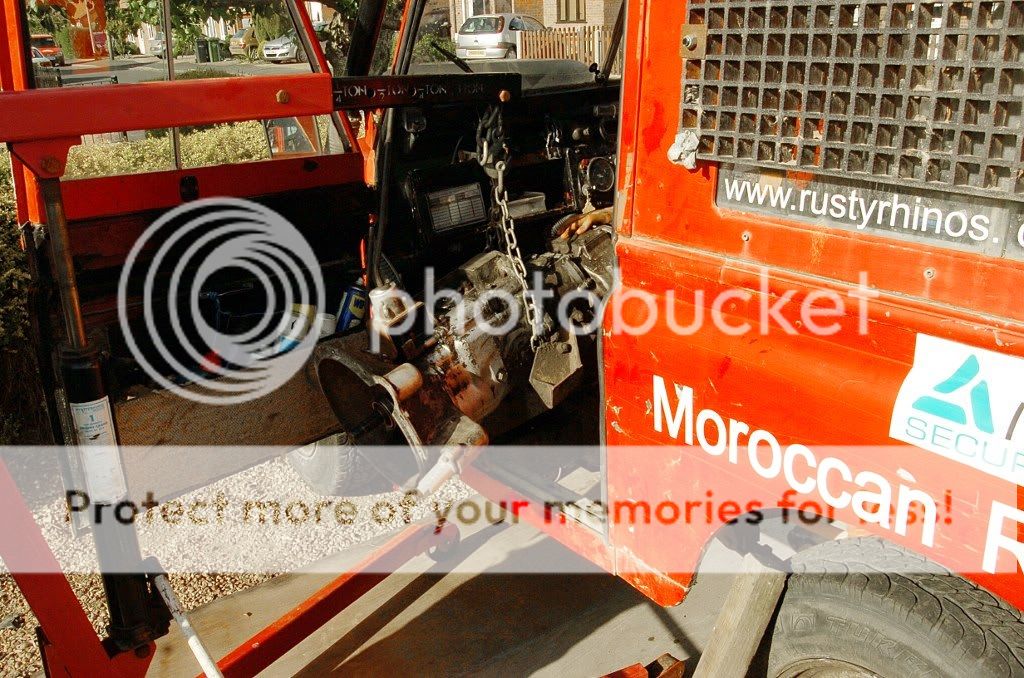

Checking transfer box and gearbox oils in the regular way of taking the plug out and filling it up until it leaks on you is something I have wanted to change - it is not so bad when you are not doing many miles, but when you are doing 6000ish miles in two weeks it is often easy to let the level checks slip now and then. So to make it easier, got hold of a "kit" from Rocky Mountain - which I have to say I am very impressed with on the telephone and by the kit itself. Instead of a blank plate on the top transfer box instead it is replaced with a plate with a filler. We would normally make this sort of thing ourselves but it is a very convinient kit, not very expensive and wanted to fit it before the trip.

So instead of the plug which you have in the transfer box as a level/filler you have the filler in the top of the box but a dipstick where the plug would be - accessible via the cab.

For various reasons our seatbox is not standard so it does not have the access panel in the regular way, so I made a hinge for access (I did not want a full length hinge):

So now it is a case of remove seatbox, open flap and check level - which I much prefer to getting under the car:

The whole idea of this was to speed things up, so converted the bolts into wing-nut-bolts-made from a washer (patent pending

):

And now to do similar for the gearbox. The normal way to fill it up and check check levels is via the plug (and top fill, if fitted) but wanted to make it simpler to check levels. Rocky Mountain do not sell the dipsticks on their own and only sell the transfer box "kits" but he sold me two "kits" and kept the transfer plate and sold it at a reduced rate - perfect As I found out, the dipstick is just long enough so that it can be accessed where you could normally fill up the gearbox (if you dont have a top mount fill). My box tunnel is one without the hole and bung, so nipped out and bought a 3" hole saw and made it so. I happened to have an older gearbox tunnel kicking about and therefore a blanking grommet to finish it off. Sorted!

So after the above we took it to Morocco and the Western Sahara and back.

Things to add to the list of repairs:

Paint the chassis where it was welded

Repair/replace exhaust manifold and downpipe. Replace mid and rear section as I had to lob it off

Fix hole in rear tub caused by a rock flicking up

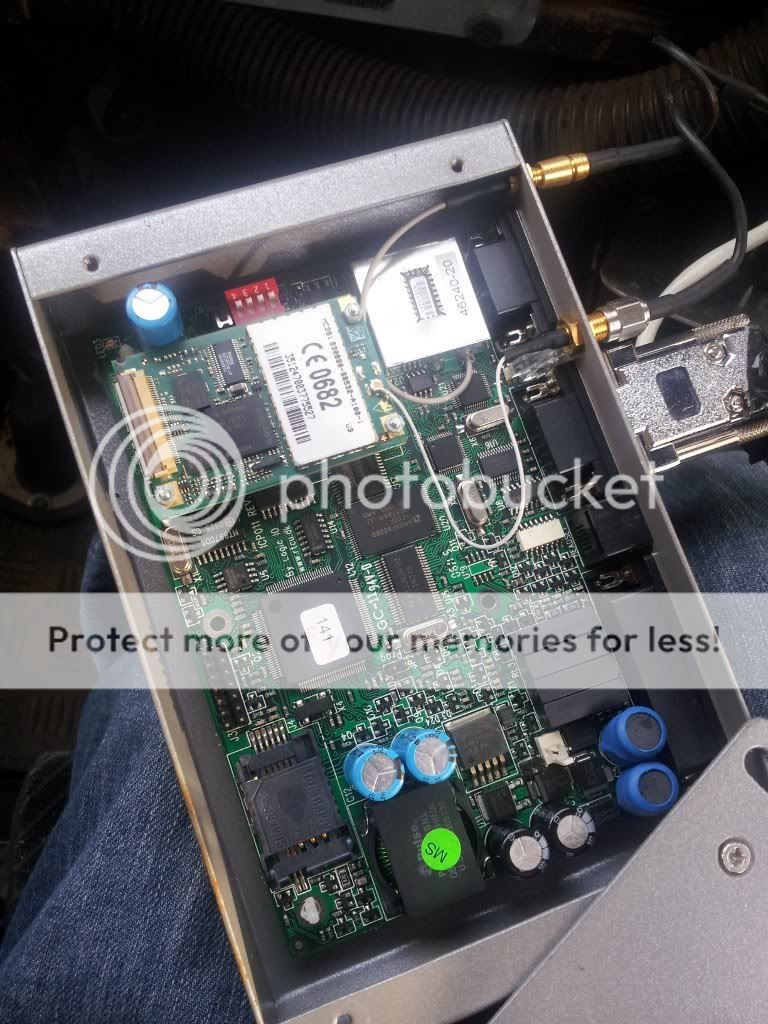

Repair tracker

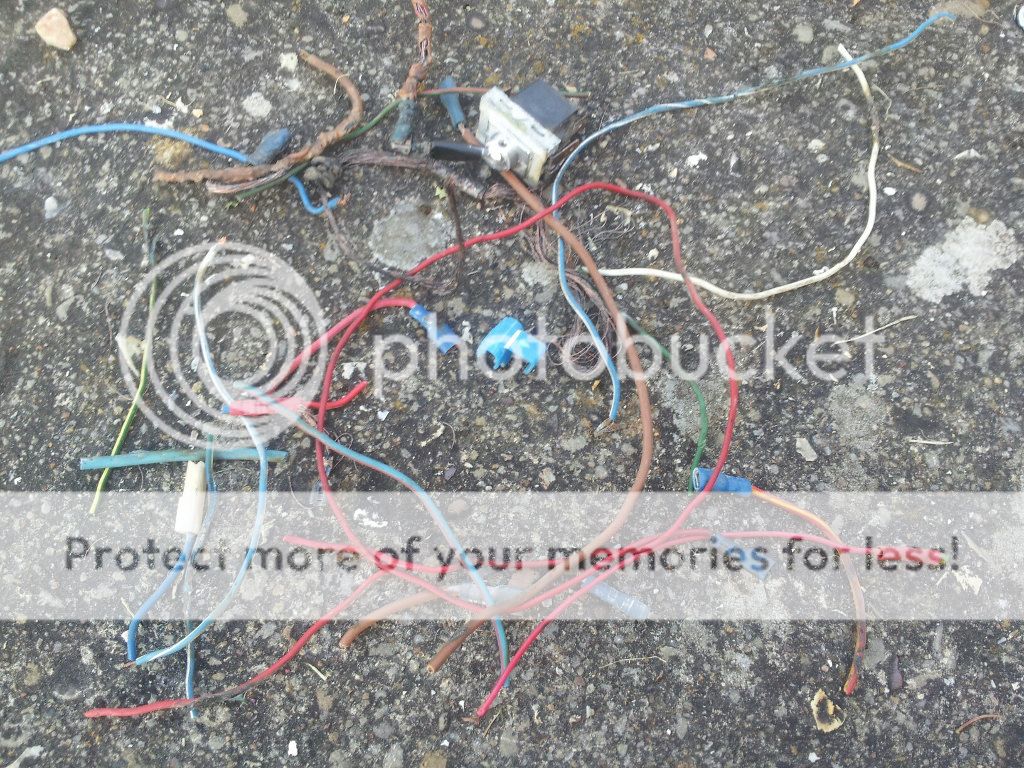

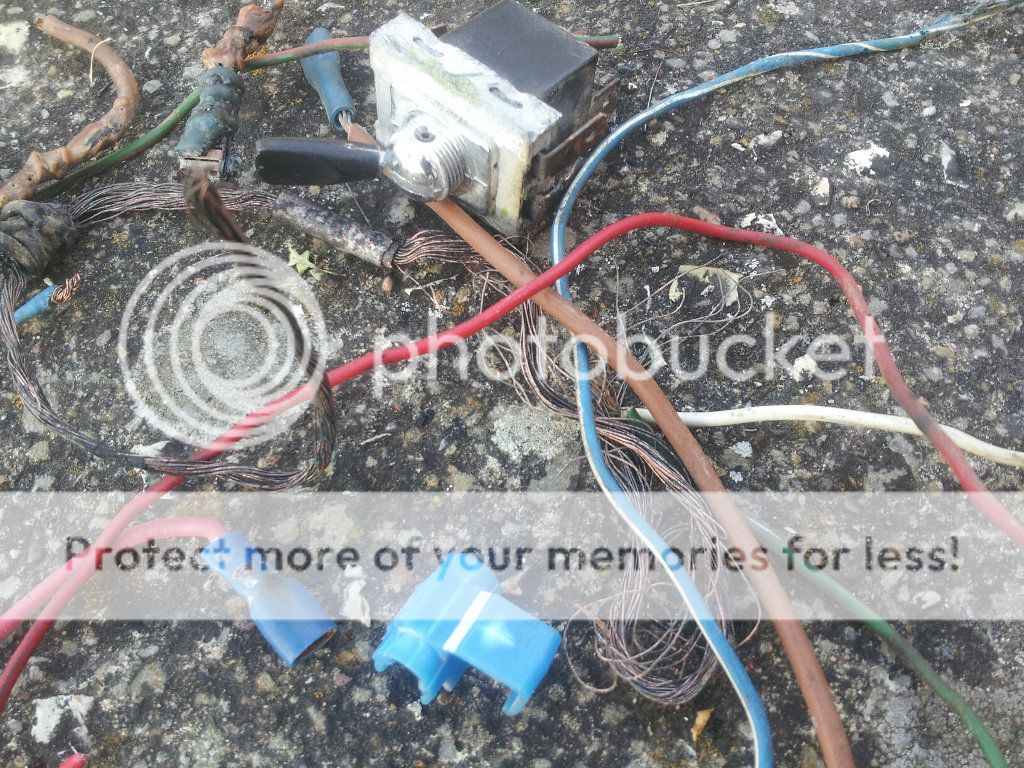

Fix lights as random things are happening (including bulbs falling out on fast paced off road driving)

So all-in-all not a lot considering the hammering it got.

It's now March 2013. We have decided where we are going next and Red needs to be seriously strong to be able to survive it. I have known for a while that the steering box is pretty much at the end of it's life. Of course, I have a spare one of those too and that is in much better nick than mine...have already got it stripped down and is pretty good only needs a few bits doing. At the same time I will replace the steering box relay and arms and the track rods.

It needs to be able to take a hammering. So I ordered a set of heavy duty steering bars and track rod ends. They should do the job nicely - decent thick wall and shouldn't corrode for a while. Greasable nipples on the track rods of course. Yeah essentially they are are simply bits of rod with a thread made at the end and we could have made them ourselves...but if I am not careful this year I will end up getting nothing done!

It has been an ongoing joke that in most of our videos we have a side light out or two. This is down to using non-genuine equipment which use plastic bases. Many people don't have a problem with these style of lamps and are widely used...but if you hammer them off-road for a few thousand miles the metal in the bulbs from shaking about wears down the plastic base and the bulbs pop out. Only £20 for a whole set but it gets a bit old after a while. Various techniques on the rally were used such as wedging in bits of cardboard and so on...but it is not ideal. They are 5 times the cost, but the Genuine Lucas lamps have a metal base so they will last much longer. They are a bit of a pain to get the bulbs out to be honest but willing to pay that price.

Quite possibly the only shiny bit on our Landie!

Before:

I mentioned our plans for 2014 to one of our main suppliers of Land Rover bits

L. R. Series Ltd - specialists in land rover, land rover series and range rover - gearbox, axle, transmission parts, spares and major units that we were looking for sponsorship and they gave us a very generous donation towards the parts that we need! Excellent stuff! So now we have a big box of most of the bits we need to take with us for spares such as UJs, wheel bearing kits etc as well as some bits that we need to rebuild the steering box and valves, springs etc for when I get round to rebuilding the head which is a must before I go on the next trip. Also got a Polybush set for the springs. So...cheers LR series

top guys.

HD Steering bars and new joints fitted. Did the steering box relay at the same time...steering is now transformed

I *might* get away with not having to do the steering box now...but we will see. Also took it down to the local garage to check the emissions and fuel mix as I have not checked it since I have changed various bits over on the engine. He tells me it is as clean as a whistle and fuelling is spot on - quite happy with that considering I did the timing and carb setup by ear.

New steering arms fitted. They are triple the weight of the originals and they were not light in the first place. Still..means when I bash them they have a better chance of surviving. Many prefer to fit a steering arm guard instead but I prefer not to - if you get stuck in sand/mud the guard acts as a scoop when you try to reverse out plus means routine (daily when we are on the trip) maintenance is hindered by the guard being in the way. This is a better way to do it IMHO.

I really must make some sort of guard for the oil cooler. Been saying that for a few years now oops!

At some point I have bashed the bit of the "4" off the numberplate. I happened to be at the office...so....

Well, it amused me anyway

Another year, another MOT. Passed with no issues as far as I am concerned. Pre-prep for MOT always pays off

Not that I had to do very much.

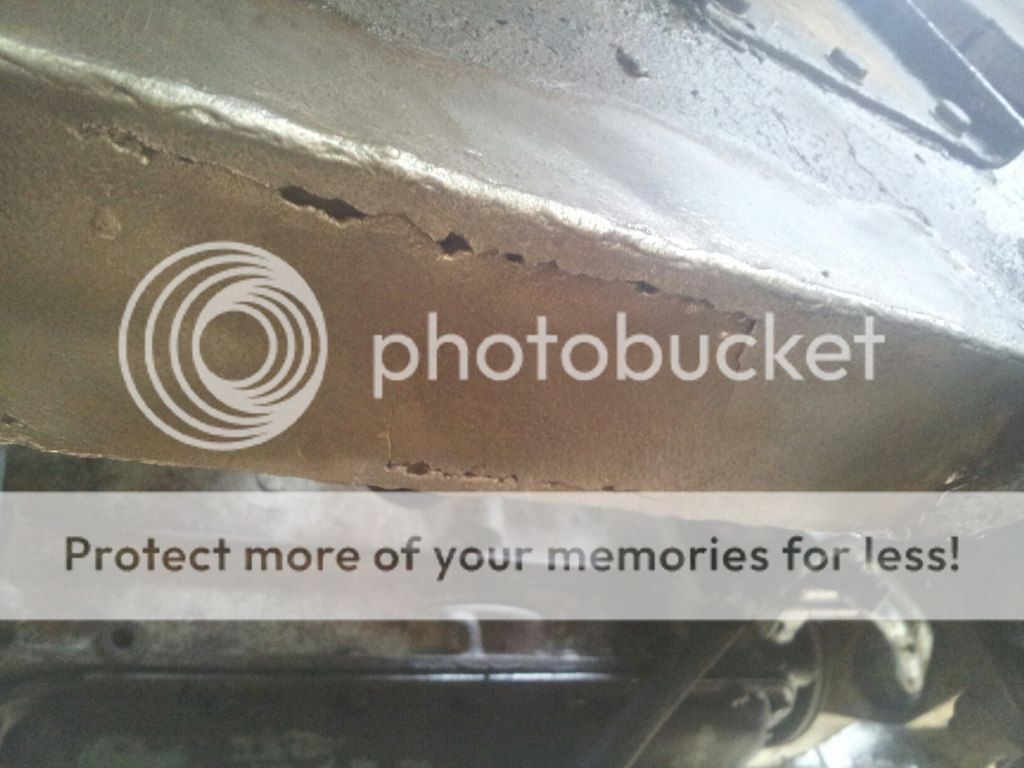

Two advisories - firstly that the "chassis has had repairs front and rear" and "gearbox and transfer box leaking". Umm... it's a Land Rover and it's 50 years old. Oh well.

It is widely considered pointless to have speakers in a Series Land Rover because the engine noise, wind noise and everything else around that rattles over powers any efforts to get some tunes. To prove this incorrect I fitted a pair of 6X9s (I either found them or got them at a boot sale, can't remember) into carpeted boxes and mounted them directly next to to listeners head. Clearly it would not be the best in terms of quality with the triangulation point being all out for a start....but it worked and proved the nay-sayers wrong.

Although it was perfectly adequate I decided recently to give it a slight upgrade. Vibe 69.4 420W 6X9s replaced the aged Pioneers

Sounding much better now but the head unit just wasn't beefy enough to give enough power to them - can only get to volume 35 out of 50 until they started peaking. So looked into getting an amplifier as well. Tried to get a second hand one but seems that most people have big ass amps designed for subs rather than smaller ones just for speakers. So I thought sod it, bought a Vibe amplifier as well. Tried various different places to mount the amp...but it's not like I have recesses under the seats or glove boxes to play with! In the end ended up screwing it to one of the speaker boxes. Not visually appealing but who cares and besides, it is out of the way of things flying around in the back and won't get wet up there like most places do.

Much happier with the volume level and quality of the sound now. Just need to figure out a way of getting speakers to the front for a bit of balance...but again it's a case of no door cards and no dashboard to mount speakers on so on the hunt for speakers I can play with to test out different ideas.

Due to Beijing Rally 2014 coming up had to strongly consider what prep we need to do to Red. The roads (well, lack of) in Kazakhstan in particular we know from experience kill cars. We snapped 7 leaf springs coming here before amongst other issues simply by the car being pounded by the tracks so we bought a new set of leaf springs to fit (going poly bush as well, just to make things easier in the future). Not going to take the body off but going to give it a good going over with the bits I can get to with grinder and wire brush to check the chassis over and re-enforce where appropriate.