Alibro

Well-Known Member

- Posts

- 7,398

- Location

- Northern Ireland

Hi guys

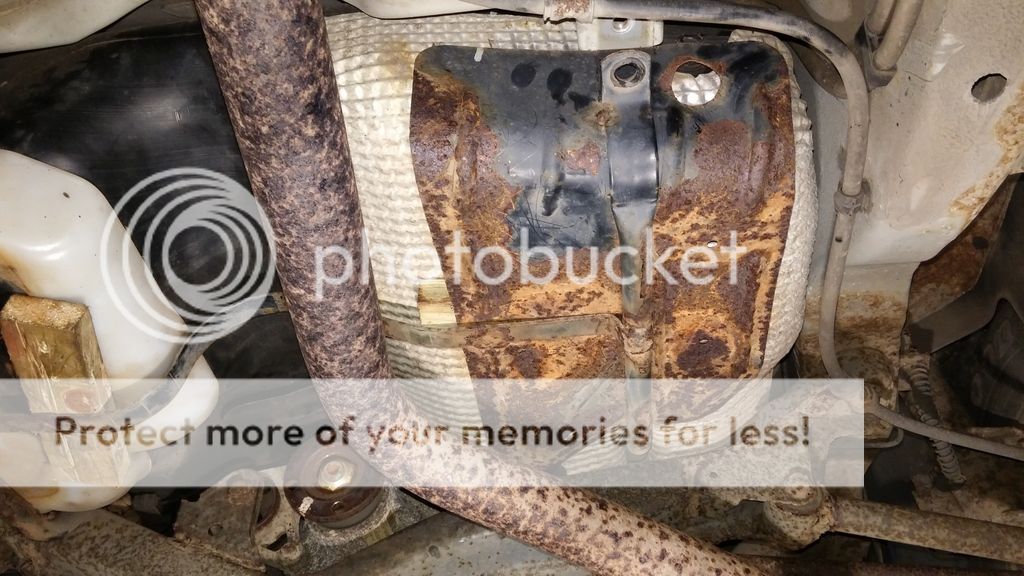

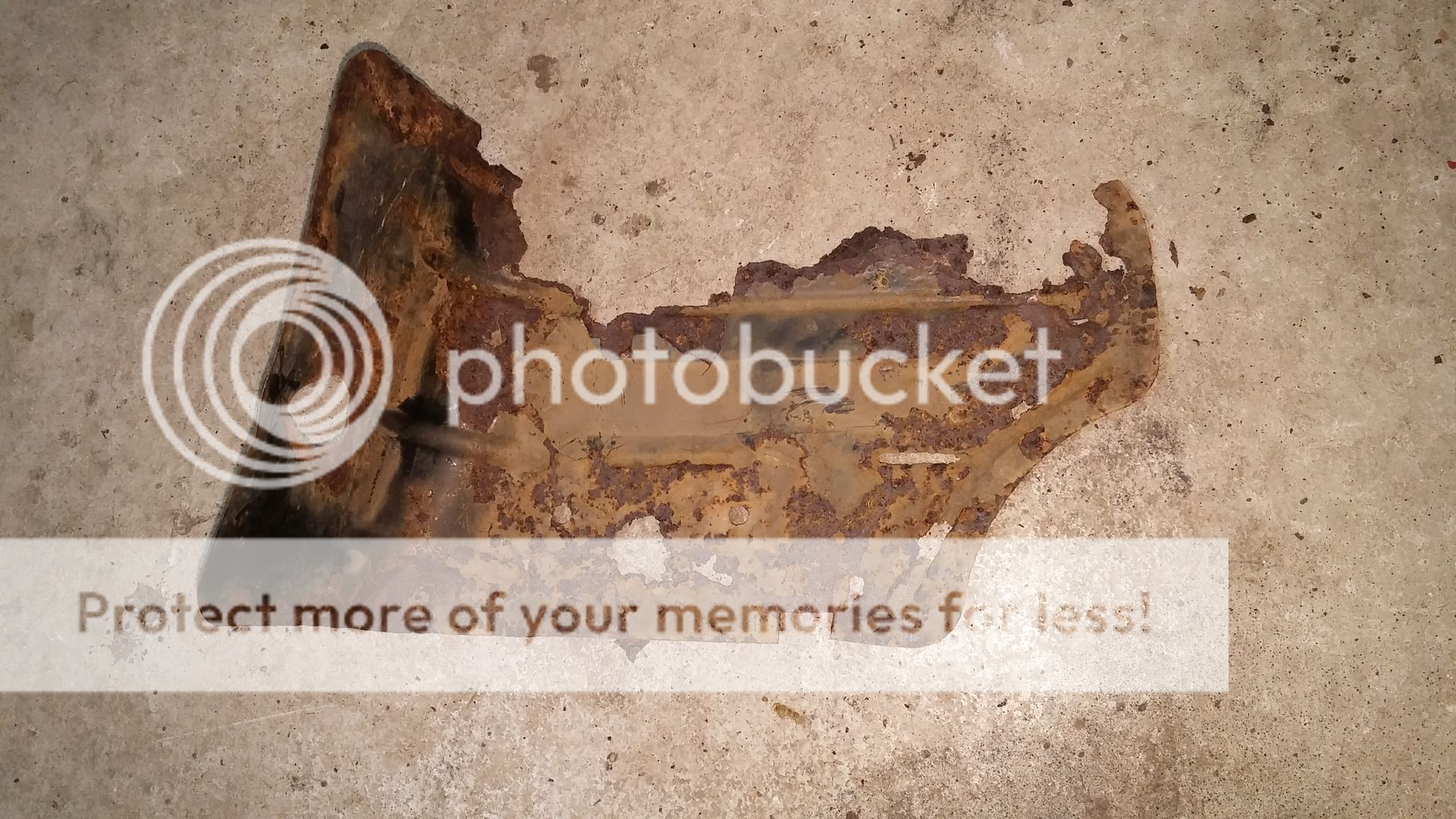

Just bought me another Freelander for a project car. Lots of pics of VCU refurb, fuel tank cradle repair etc.

Early 2015 I bought a 2004 K series Freelander from a dealer, it had full MOT, new window regulators, new diff bushes and decent tyres but because it was a K series I got it for under £1500. I thought I had done well getting such a fresh car for such small money.

Well that ain't nothin. Get a load of this, the newcomer is on the right.

Gertrude is a 2002 K series with 120k on the clock but with a replacement engine at 60k (some issue caused by the garage during a service), she comes with 2 newish tyres, two fairly worn tyres 3 dodgy windows a new clutch and possible head gasket failure (yet drove home 20 miles no probs) but the body is rust free. She has sat around untaxed or MOT'd for three years so covered in algae and moss but clean paintwork under it all.

Guess what I paid for her?

No go on guess

Ah go on

Go on, go on, go on, go on.

Ah your no fun atall.

£280! Yip thats right, £280 and she drove home (allegedly ocifer) no bother. In fact I would say she drives smoother than my 04 car.

I haven't decided what to do with it yet but will get her MOT'd and take it from there. I would love to put a 1.8T engine in like Disco_mikey did and take her off roading. I think the extra torque from a turbo would make a massive difference to the driveability in sticky conditions.

In the meantime I am going through her sorting all the issues and my goal is to have her running serviced and MOT'd for under £600.

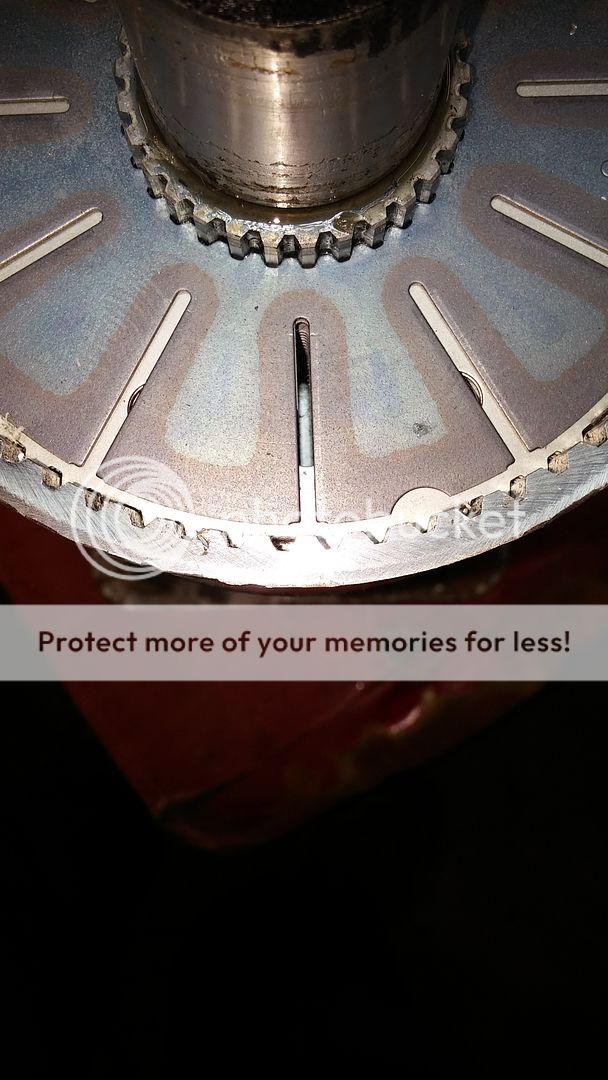

First job when I got her home was the One Wheel Up Test. Which she of course failed miserably with a time close to 2 minutes, but at least it moved. My other car was pretty well seized solid when I got her. Anyway the propshaft will be off soon so I can have a go at refurbing the VCU. The last one I did is still working fine.

Next job was checking the coolant which appeared to have no antifreeze, turns out it was full of K seal (or such crap) instead, So gave it a quick flush with the hose and I refilled with antifreeze. I should say at this point the car was advertised with possible HGF as it had "lots of steam coming out the exhaust". I'm hoping the guy had panicked and threw in K seal when he saw the steam but it is just condensation. Time will tell but I hope it was just because it had been lying for so long.

She needs the windows sorting, disks and pads but otherwise I can't find much wrong that a good clean wouldn't fix. I is a happy bunny.

Just bought me another Freelander for a project car. Lots of pics of VCU refurb, fuel tank cradle repair etc.

Early 2015 I bought a 2004 K series Freelander from a dealer, it had full MOT, new window regulators, new diff bushes and decent tyres but because it was a K series I got it for under £1500. I thought I had done well getting such a fresh car for such small money.

Well that ain't nothin. Get a load of this, the newcomer is on the right.

Gertrude is a 2002 K series with 120k on the clock but with a replacement engine at 60k (some issue caused by the garage during a service), she comes with 2 newish tyres, two fairly worn tyres 3 dodgy windows a new clutch and possible head gasket failure (yet drove home 20 miles no probs) but the body is rust free. She has sat around untaxed or MOT'd for three years so covered in algae and moss but clean paintwork under it all.

Guess what I paid for her?

No go on guess

Ah go on

Go on, go on, go on, go on.

Ah your no fun atall.

£280! Yip thats right, £280 and she drove home (allegedly ocifer) no bother. In fact I would say she drives smoother than my 04 car.

I haven't decided what to do with it yet but will get her MOT'd and take it from there. I would love to put a 1.8T engine in like Disco_mikey did and take her off roading. I think the extra torque from a turbo would make a massive difference to the driveability in sticky conditions.

In the meantime I am going through her sorting all the issues and my goal is to have her running serviced and MOT'd for under £600.

First job when I got her home was the One Wheel Up Test. Which she of course failed miserably with a time close to 2 minutes, but at least it moved. My other car was pretty well seized solid when I got her. Anyway the propshaft will be off soon so I can have a go at refurbing the VCU. The last one I did is still working fine.

Next job was checking the coolant which appeared to have no antifreeze, turns out it was full of K seal (or such crap) instead, So gave it a quick flush with the hose and I refilled with antifreeze. I should say at this point the car was advertised with possible HGF as it had "lots of steam coming out the exhaust". I'm hoping the guy had panicked and threw in K seal when he saw the steam but it is just condensation. Time will tell but I hope it was just because it had been lying for so long.

She needs the windows sorting, disks and pads but otherwise I can't find much wrong that a good clean wouldn't fix. I is a happy bunny.

Last edited: