Hi all,

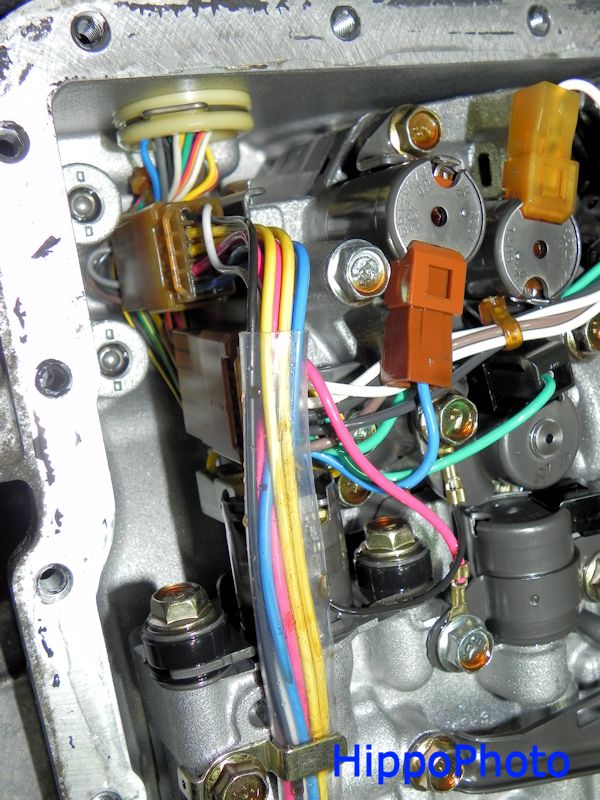

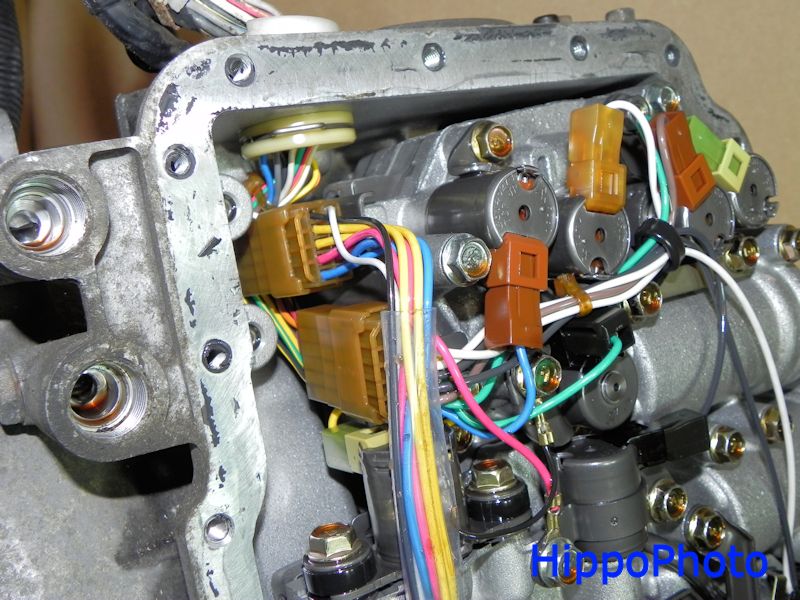

sorry wasn't on here till now didnt get a chance. Something else i forget to add is that when the Freelander starts up, the fans come on full blast, that is the twin fans at the front. Is it supposed to do this? Doesn't it do this if the system coolant temp sensor is faulty? Also, there's one cable emerging from the gear selector housing area underneath the centre (some ppl call it rear)console. It's a skinny black cable which emerges from thatarea and runs to the passenger footwell and just sits there on the floor like that cold so to speak, not connected to anything. The cable connector is small and round, i actually confused it for a radio aerial connecter. The connector itself is brown while the rest of the cable is black. I took a series of photos today but wont have the card reader till tomorrow to download them sorry guys, then will upload it.. But it cant be the aerial as i found the aerial which is another skinny black cable with a single pin only plus it's in the radio area whereas this one emerges from the gear selector housing area.

Portchy - mated the gearbox housing successfully to the engine block. It was pretty simple as i mated them outside of the car, i had one up on one hoist, the other on another, when they came together, i didnt force anything but turned the flywheel just a little till they engaged successfully. Then i did all the bolts to the RAVE torque specification.

Hippo - the multimeter i got is cheap and nasty, a no name brand unfortunately, it says made by SCA which stands fo Super Cheap Auto and Made in PRC, speaks for itself.. maybe that explains the values jumping?

As for a code scanner, i dont have Hawkeye or testbook so tomorrow i'll bring my laptop and try this one software i have see if works, if not then i'll ring a mobile guy to come around and scan it, as you said, the self diagnostic system will tell me where a fault lies.

Speaking of cables and connectors not connected to anything, mine doesn't have a radio as it was nicked prior to me buying it a few months ago, so there's a hole there, i'll get a radio in due time. There's a large square black multiplug in there i can see which has 2 further short cables running from it, one of those cables has a yellow connector the other a grey one. These 2 connectors are dangling and arent connected to anything. The buttons on the front console have 3 spare one where nothing's connected so i initially thought these 2 must belong to such, but i dont think so when i found a further 2 connecotrs, blue and black, not connected to anything, that look more like the type that connect to the back of the buttons, the blue has 6 holes in it the black has 5.

Have taken photos will upload tomorrow.