@Ross Tait Thanks for the like ! Any idea why there should have been a delay on all coming good after fitting new O2 ?? Thanks

Given when you put the new o2 sensor in that as you described problem 1 was gone and the fuel trims looked fine to me I would suspect reason number 2 above.

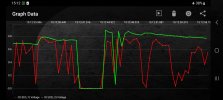

The only thing I noticed slightly different between your new o2 sensor reading vs your old known good was the switching rate. There was a lot more up down happening but I guess that could just be accounted for by the fact that this is a new o2 sensor and your known good may have been not brand new? Maybe that’s the only reason for the difference I saw.