Alibro

Well-Known Member

- Posts

- 7,448

- Location

- Northern Ireland

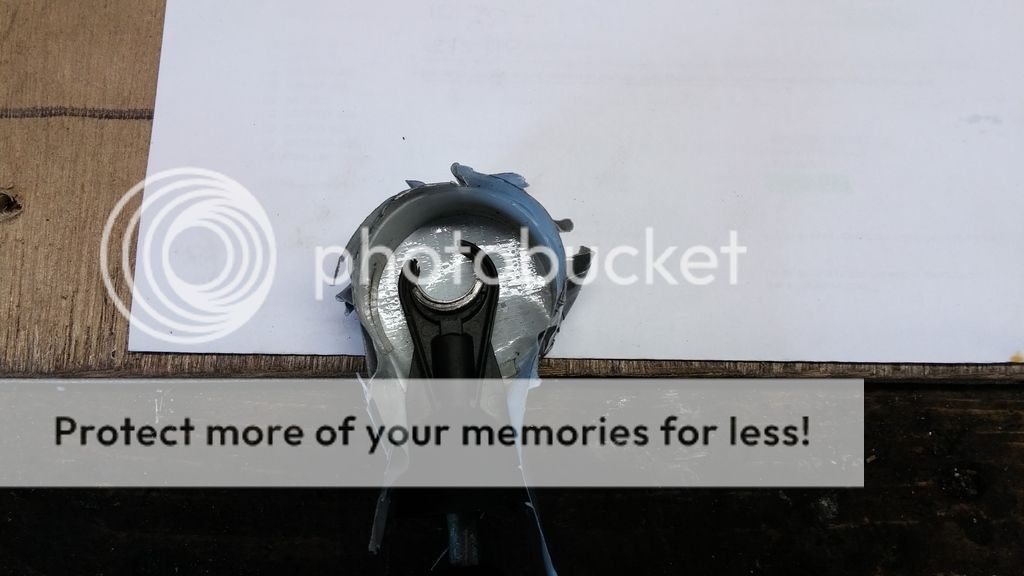

This is the thrust bearing as promised. The mating surface has something very sticky on it. There is a fair amount of copper grease has been used else where and I'm wondering if this had been smeared on the mating surface would it go sticky like this. I'm concerned this might be the issue as my mate who was preping the thrust bearing (and is much more experienced than me) smeared grease in the same way on the new one

You can see bottom right I cleaned it off. Any thoughts as to whether this might have been the cause of the shudder and should I be worried?

You can see bottom right I cleaned it off. Any thoughts as to whether this might have been the cause of the shudder and should I be worried?

Last edited: