Wot e sed .. ^

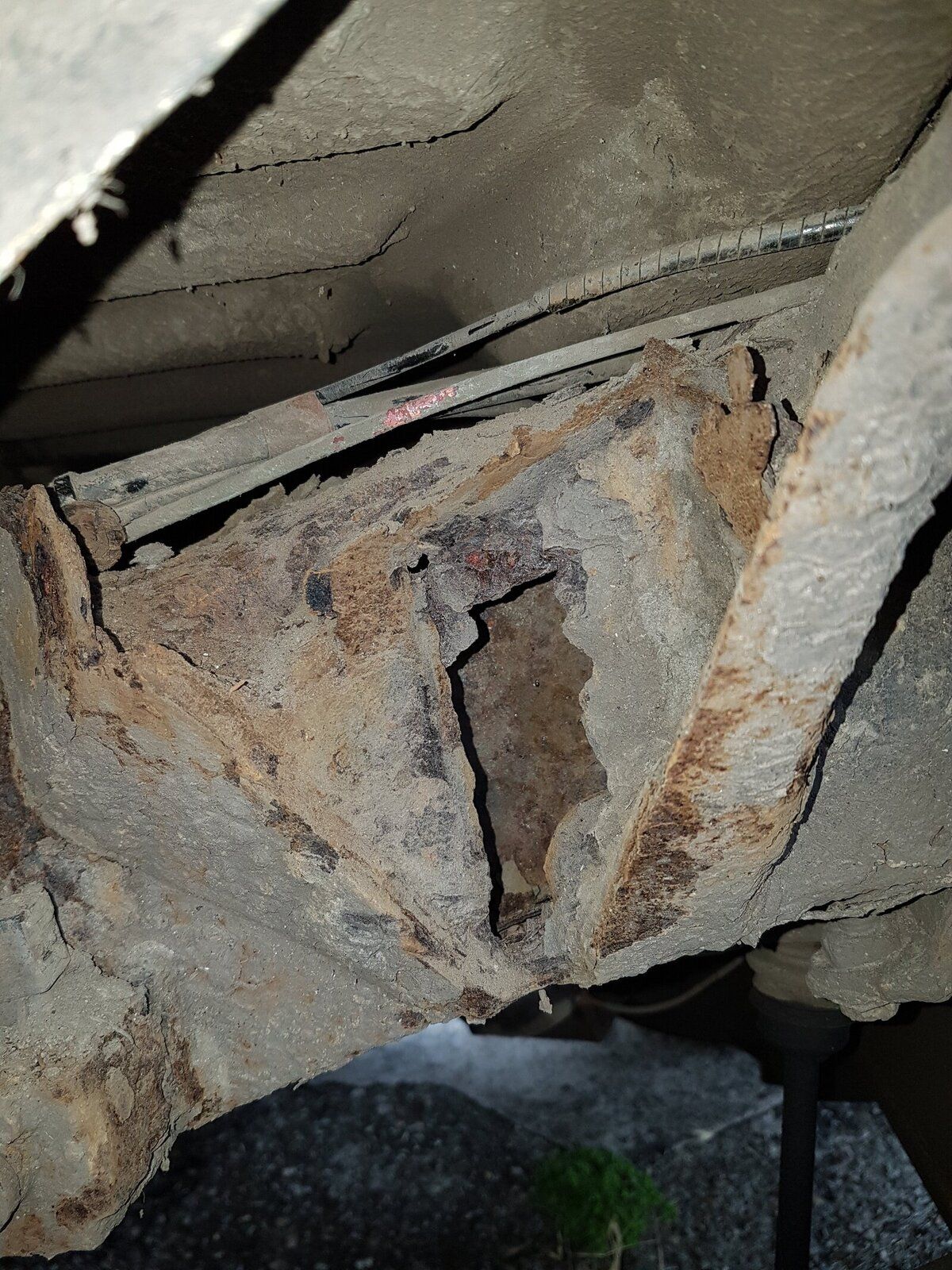

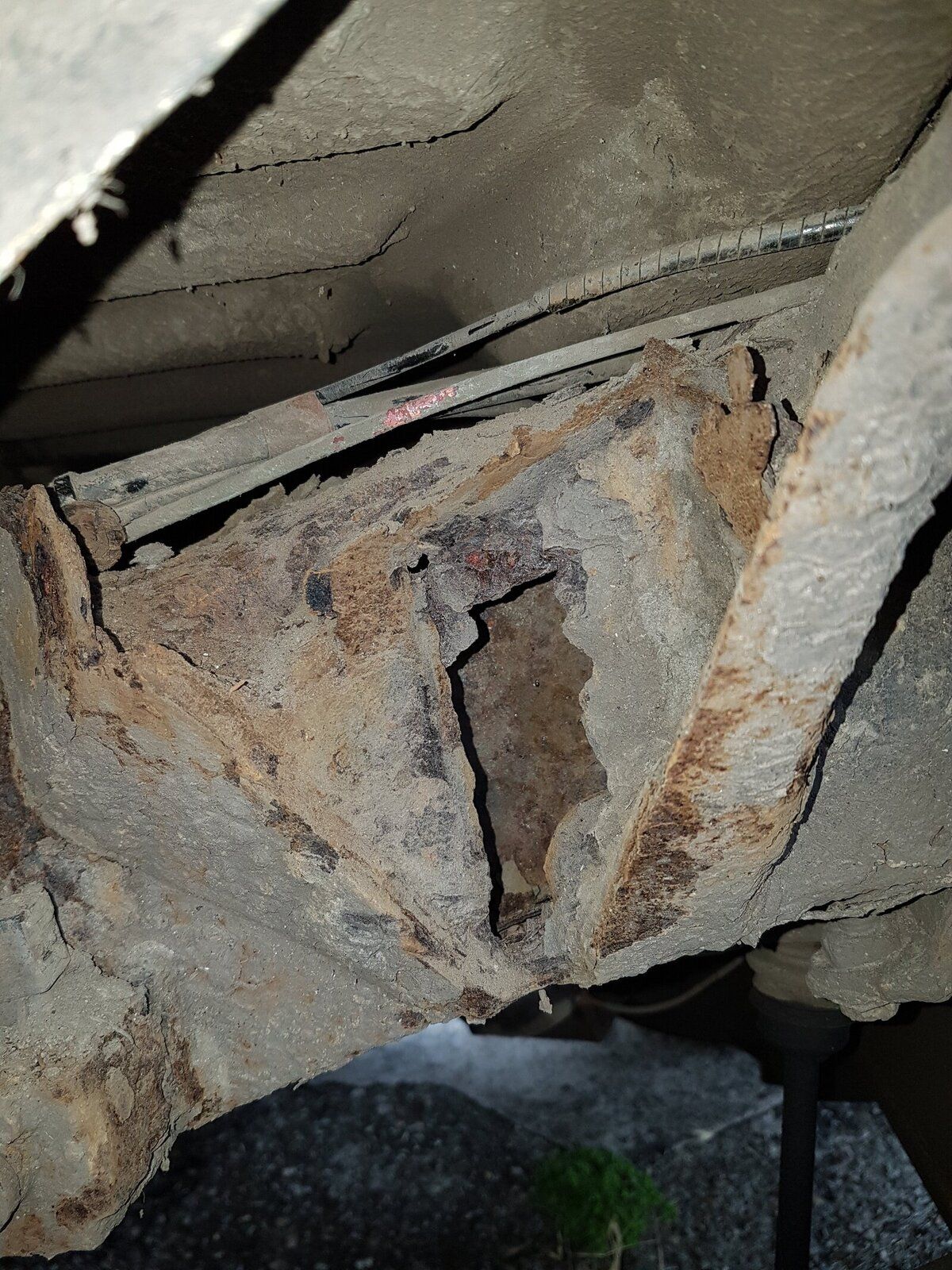

Quite a bit of work needed there, the rot all needs cutting out until you have proper, shiny metal, not rust. I'm surprised you could even get it to weld onto the rust in the first place! Hit it with a hammer to knock the holes wider till they stop expanding, then cut it all out, grind back to solid. Then you need make repair panels fabricated from sheet steel and welded in place, then you can look at the suspension mount.

However .. Once you start hitting it to find where it 'rings' (good steel) bear in mind that D2's rot their chassis for breakfast, so you might have to cut away a lot more than is apparent at first sight.

I'd give serious thought to properly checking the other side too ... and the spring mounts, A-frame mounts etc, indeed the whole chassis! Start with a steam clean or a good, powerful, pressure wash ..