TonyOZ

Member

- Posts

- 45

- Location

- Adelaide Australia

Hi

I have just picked up a Freelander cheap because of a gearbox issue. I'm hoping that I can get away with swapping a shift solenoid or two and trade may way on towards a rust free early Series 2. Yes, there are still plenty of them in Australia!

The symptoms are a random change down from 4th or 5th to 2nd but only after running for about 20 minutes. ie when hot. I say 4th or 5th because I can’t tell as the gear indicators both on the dash and next to the shifter constantly read Neutral. I have also noticed a slightly more harsh shift than normal on occasions.

I have no error codes on the dash but have not plugged in a Land Rover specific diagnosis tool. I have not yet checked pin resistance but will do so over next couple of days. I’m inclined to expect the cold resistance to be no indication of the hot resistance though.

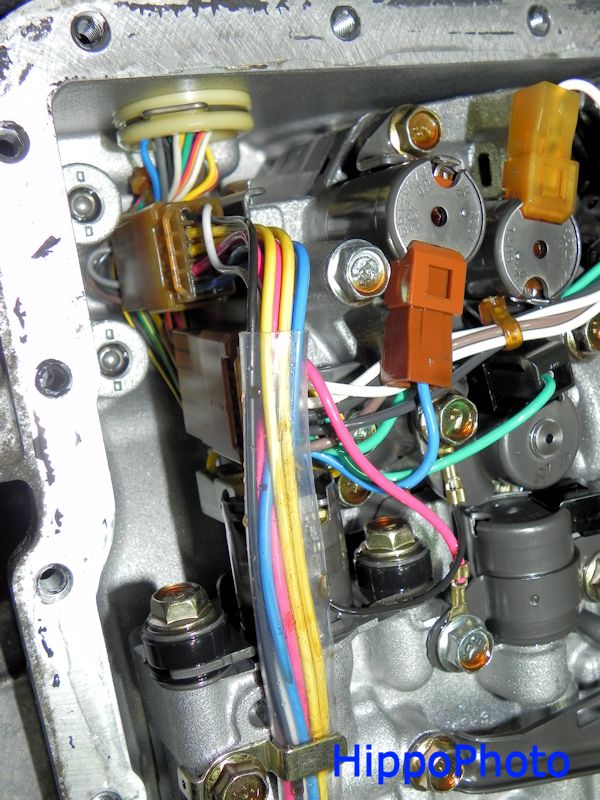

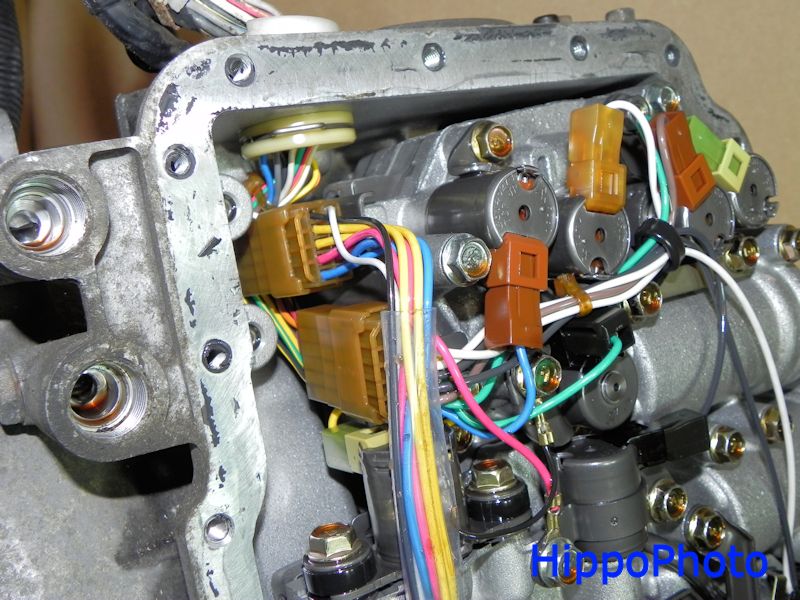

My gut feel is to replace the:

·2-4 duty brake solenoid

·Line pressure duty solenoid; and

·2-4 brake timing solenoid

and see how it goes.

Any advice would be much appreciated.

I have just picked up a Freelander cheap because of a gearbox issue. I'm hoping that I can get away with swapping a shift solenoid or two and trade may way on towards a rust free early Series 2. Yes, there are still plenty of them in Australia!

The symptoms are a random change down from 4th or 5th to 2nd but only after running for about 20 minutes. ie when hot. I say 4th or 5th because I can’t tell as the gear indicators both on the dash and next to the shifter constantly read Neutral. I have also noticed a slightly more harsh shift than normal on occasions.

I have no error codes on the dash but have not plugged in a Land Rover specific diagnosis tool. I have not yet checked pin resistance but will do so over next couple of days. I’m inclined to expect the cold resistance to be no indication of the hot resistance though.

My gut feel is to replace the:

·2-4 duty brake solenoid

·Line pressure duty solenoid; and

·2-4 brake timing solenoid

and see how it goes.

Any advice would be much appreciated.