- Posts

- 4,659

- Location

- Near Heathrow.

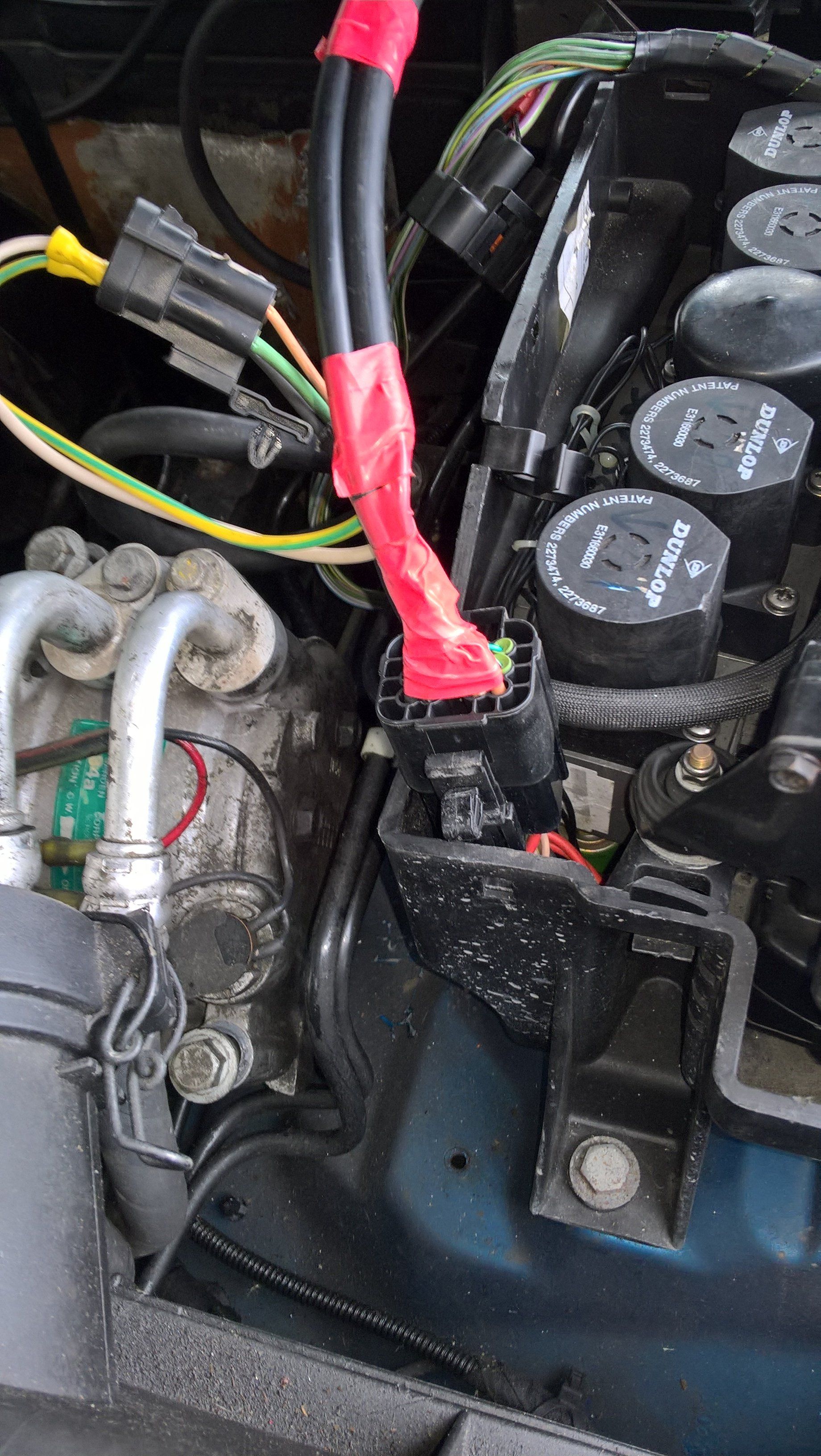

Made this to make EAS garage activities easier. Connects direct to Driver Pack & Compressor, with croc-clips to connect to battery. Doesn't need ignition on, or ECU working.

White cable is battery power in. Thick black cable is pump & driver pack power. Thin black cable for driver pack trigger signals.

Found the correct female EAS multi-pin connector on eBay complete with new sockets, etc.

12V air solenoid in place of pump.

- Big button switches power to compressor, plus there's a relay inside linked to the pressure switch to shut off the compressor when the tank is full.

- Four buttons for corners, plus Inlet & Exhaust.

- 12V air-solenoid to use in place of EAS Pump, enables running system from garage compressor.

White cable is battery power in. Thick black cable is pump & driver pack power. Thin black cable for driver pack trigger signals.

Found the correct female EAS multi-pin connector on eBay complete with new sockets, etc.

12V air solenoid in place of pump.