Hi all from Kuala Lumpur, Malaysia,

My first post here and hoping someone can help.

P38 DSE engine is difficult to start and when it manage to start, it will run at anything above 1200 RPM. At this point, if I release my foot from the throttle even a bit, it just stalls and died.

History: My DSE overheated 2 yrs ago. It didn't cracked or warped the head, just surface rot (grey rust) to a point the pressure from one of the valves had leaked into the coolant waterways.

Work done: welded and skimmed the head, replaced all pistons rings, replaced in-tank pump, serviced the FIP and the solenoid checked, serviced all injectors (checked Injector #4 for electrical signals w/ multimeter, there is signal but don't know if correct or not), replaced all leak-off pipes.

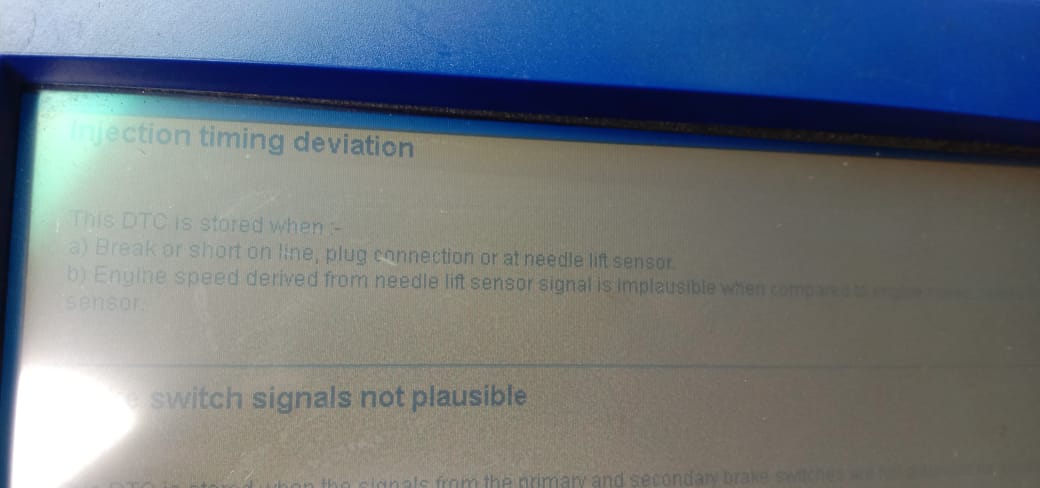

Autologic (see pic from workshop below): returned this message:

Injection timing deviaton.

This DTC is stored when:

a.) break or short on line, plug connection or needle lift sensor.

b.) engine speed derived from needle lift sensor signal is implausible when compared to ... (illegible) sensor.

Does this means Injector #4 is bad. I hope not as it is almost impossible to find one in Malaysia, I can eBay it of course, but am hoping for the wisdom of the many here to point to a solution before I eBay the costly injector #4, if that's where the fault lies.

I am really frustrated as the car was running fine, which means injector #4 was fine, prior to overheating and having do the head work done.

I thank everyone in advance for all advise.

Best wishes from me.

My first post here and hoping someone can help.

P38 DSE engine is difficult to start and when it manage to start, it will run at anything above 1200 RPM. At this point, if I release my foot from the throttle even a bit, it just stalls and died.

History: My DSE overheated 2 yrs ago. It didn't cracked or warped the head, just surface rot (grey rust) to a point the pressure from one of the valves had leaked into the coolant waterways.

Work done: welded and skimmed the head, replaced all pistons rings, replaced in-tank pump, serviced the FIP and the solenoid checked, serviced all injectors (checked Injector #4 for electrical signals w/ multimeter, there is signal but don't know if correct or not), replaced all leak-off pipes.

Autologic (see pic from workshop below): returned this message:

Injection timing deviaton.

This DTC is stored when:

a.) break or short on line, plug connection or needle lift sensor.

b.) engine speed derived from needle lift sensor signal is implausible when compared to ... (illegible) sensor.

Does this means Injector #4 is bad. I hope not as it is almost impossible to find one in Malaysia, I can eBay it of course, but am hoping for the wisdom of the many here to point to a solution before I eBay the costly injector #4, if that's where the fault lies.

I am really frustrated as the car was running fine, which means injector #4 was fine, prior to overheating and having do the head work done.

I thank everyone in advance for all advise.

Best wishes from me.