fenby1976

New Member

- Posts

- 1,036

- Location

- West Wales

Cheers fenners,

that doesnt look so hard, I dont have any 1 bi 2, but I've loads of flat bar, a chunk of 6mm bi 50 should take care of that.

I nearly bashed the crap out of mi front panel, but looking at yours its not necessary.

I did have to cut away a load more of the battery tray, as the oil cooler pipes would not go in, looks like you have too, did you have some more pipes made up or re they the originals, I think I might just be able to get them to reach original lengths.

I wanted a bit of reassurnace with all the work I've put in so I lashed mine up today and had her running, sounds cool, nearly as good as a common rail, cant wait to go for a razz, wont be doing any off roading straight away, theres no clearance under mi exhaust for now.

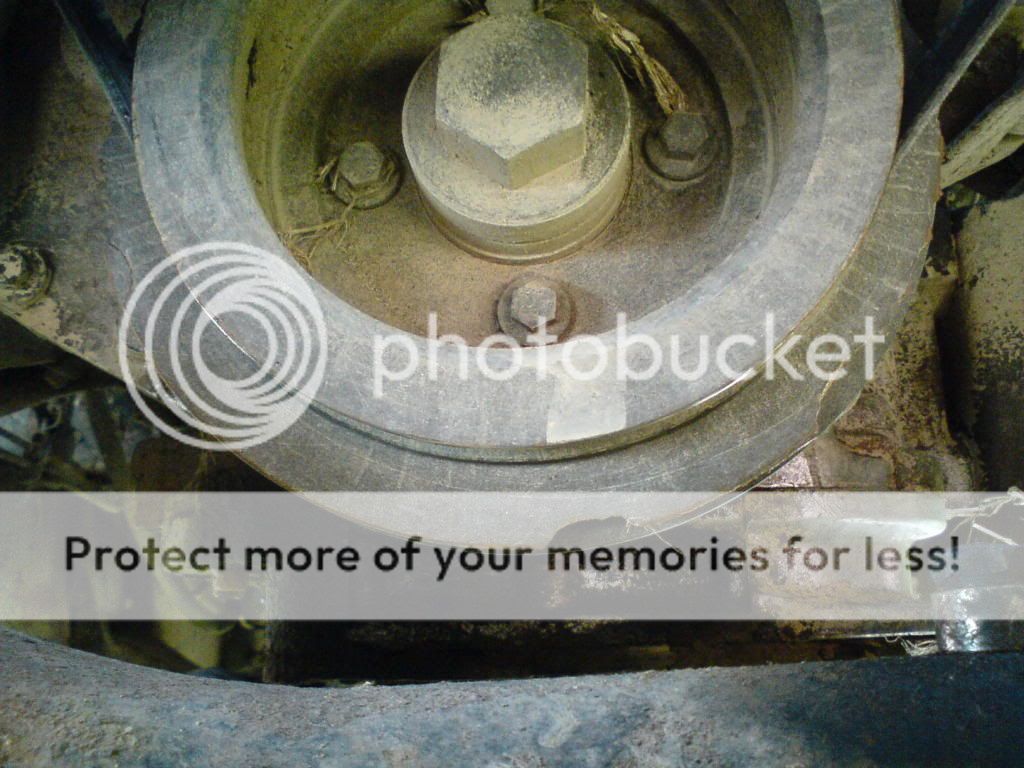

The battery tray had to go, but the original Disco oil cooler pipework just about fits - I'll need to fabricate some supports for it though. I wouldn't have thought you'd have enough room to put the intercooler where mine has gone because all those ancilliaries on the nearside of your engine are taking up a lot of space. I think that putting a 300tdi intercooler infront of the main radiator would be a better bet for you. I think you might be able to mount it by drilling a couple of holes in the top of the front X-member and another couple in the slam plate of the front pannel, for the locating pegs on the intercooler.

Better than common rail I'd say - no ECU to go wrong when wading.