steve2286w

Well-Known Member

- Posts

- 5,074

- Location

- monkeyangerland

I got this engine off eBey nearly five years ago, the lad I got it off removed it from a 95 discovery EST 115k miles , no knocks or smoke

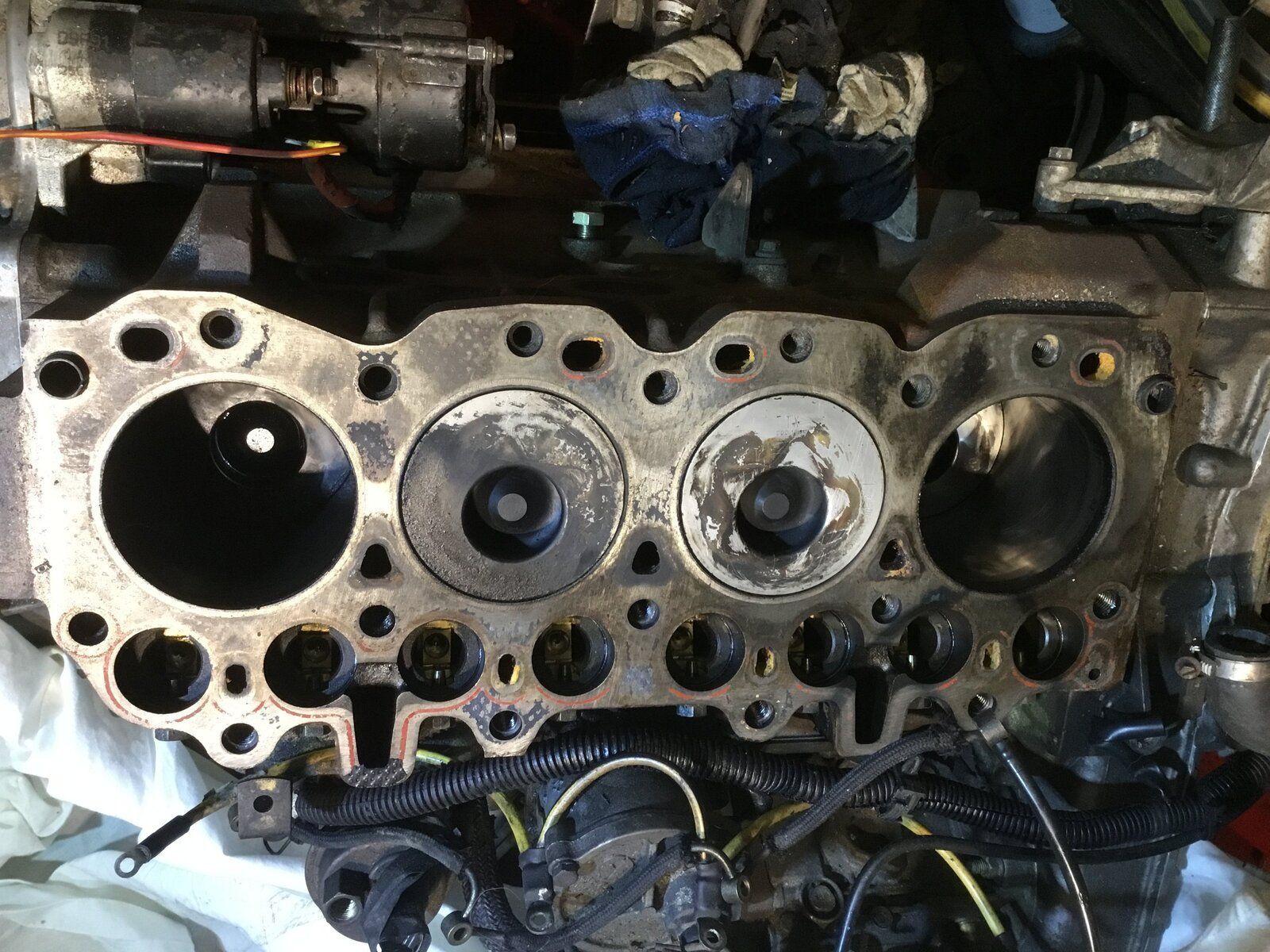

I took the head off at the weekend to remove a snapped heater plug, there is no wear ridge at top of any cylinder , however there is a vertical scratch on no 4 , I can feel with fingernail.

I have not measured bores yet. You can see some honing marks on bores

The markings on pistons indicate std pistons TX ERR 1387 STD

I’m unsure if the engine has been refurbed before by previous owners

So questions

If you have stripped one before Do the fitted pistons with those markings look original Land Rover

Would you feel reasonably ok running it with scratch like that

Would the honing marks still be visible from 1995

Would scratch hone out if diameter allows, otherwise rebore one pot?

What should I look for that would help prove it has not been refurbed previously

I’m feeling I need to strip it down a bit to check bores and clean and reassemble at the minimum

With clean and regrind valves

I have prepped the bellhousing for series 3 and did a timing belt change. A year ago

Cheers

Steve

I took the head off at the weekend to remove a snapped heater plug, there is no wear ridge at top of any cylinder , however there is a vertical scratch on no 4 , I can feel with fingernail.

I have not measured bores yet. You can see some honing marks on bores

The markings on pistons indicate std pistons TX ERR 1387 STD

I’m unsure if the engine has been refurbed before by previous owners

So questions

If you have stripped one before Do the fitted pistons with those markings look original Land Rover

Would you feel reasonably ok running it with scratch like that

Would the honing marks still be visible from 1995

Would scratch hone out if diameter allows, otherwise rebore one pot?

What should I look for that would help prove it has not been refurbed previously

I’m feeling I need to strip it down a bit to check bores and clean and reassemble at the minimum

With clean and regrind valves

I have prepped the bellhousing for series 3 and did a timing belt change. A year ago

Cheers

Steve