Despite chasing my tail for a suspected boost or fuelling issue for weeks, I've managed to make the most significant improvement so far. All with a few strips of old bicycle innertube. We'll get to that, though. Best get the last couple of week's jobs logged and out of the way.

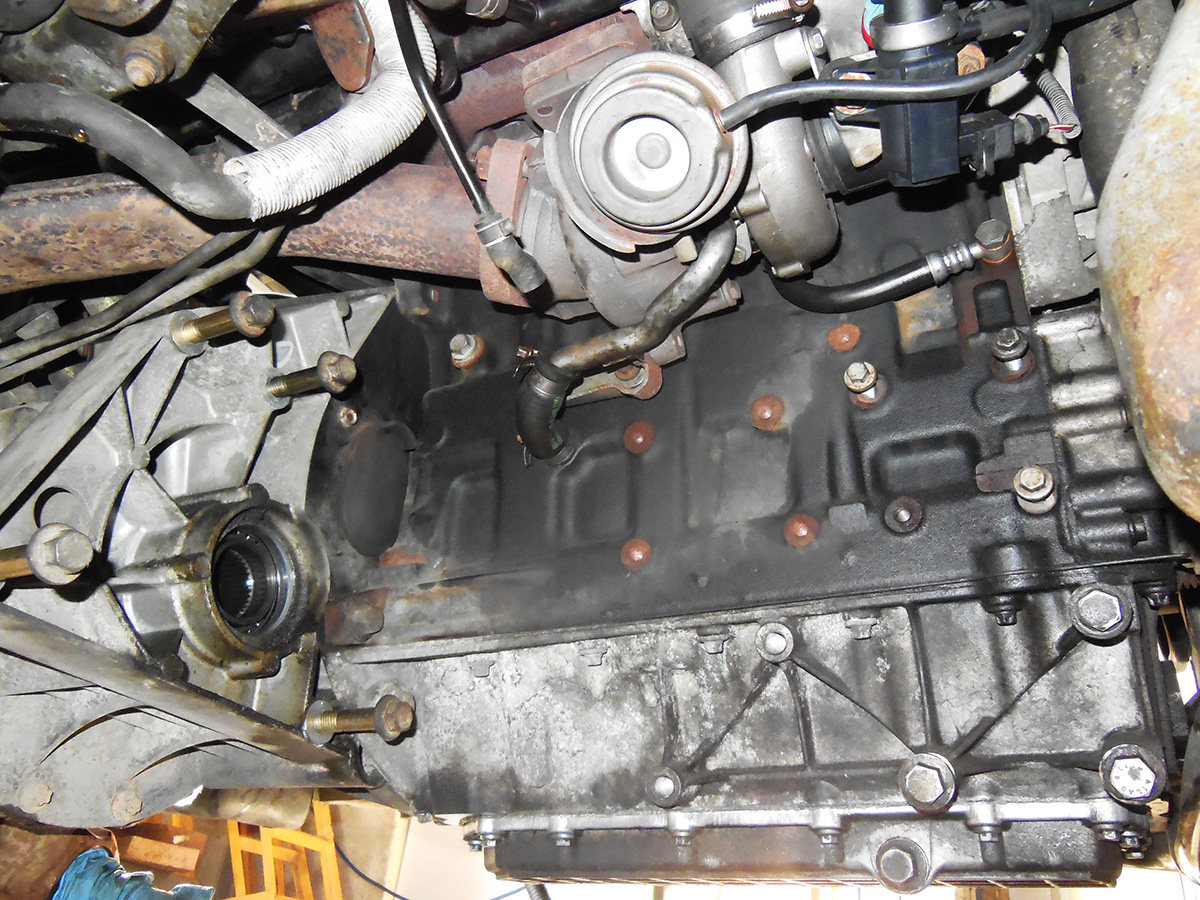

Eagle eyes may have spotted an alternator in the background of some of the earlier IRD photos. An intermittent battery light that I'd chalked up to 'atmospheric conditions' (see post 14) finally reared its head permenantly. I was able to temporarily recover it by hitting it with a hammer but that's not a long term solution

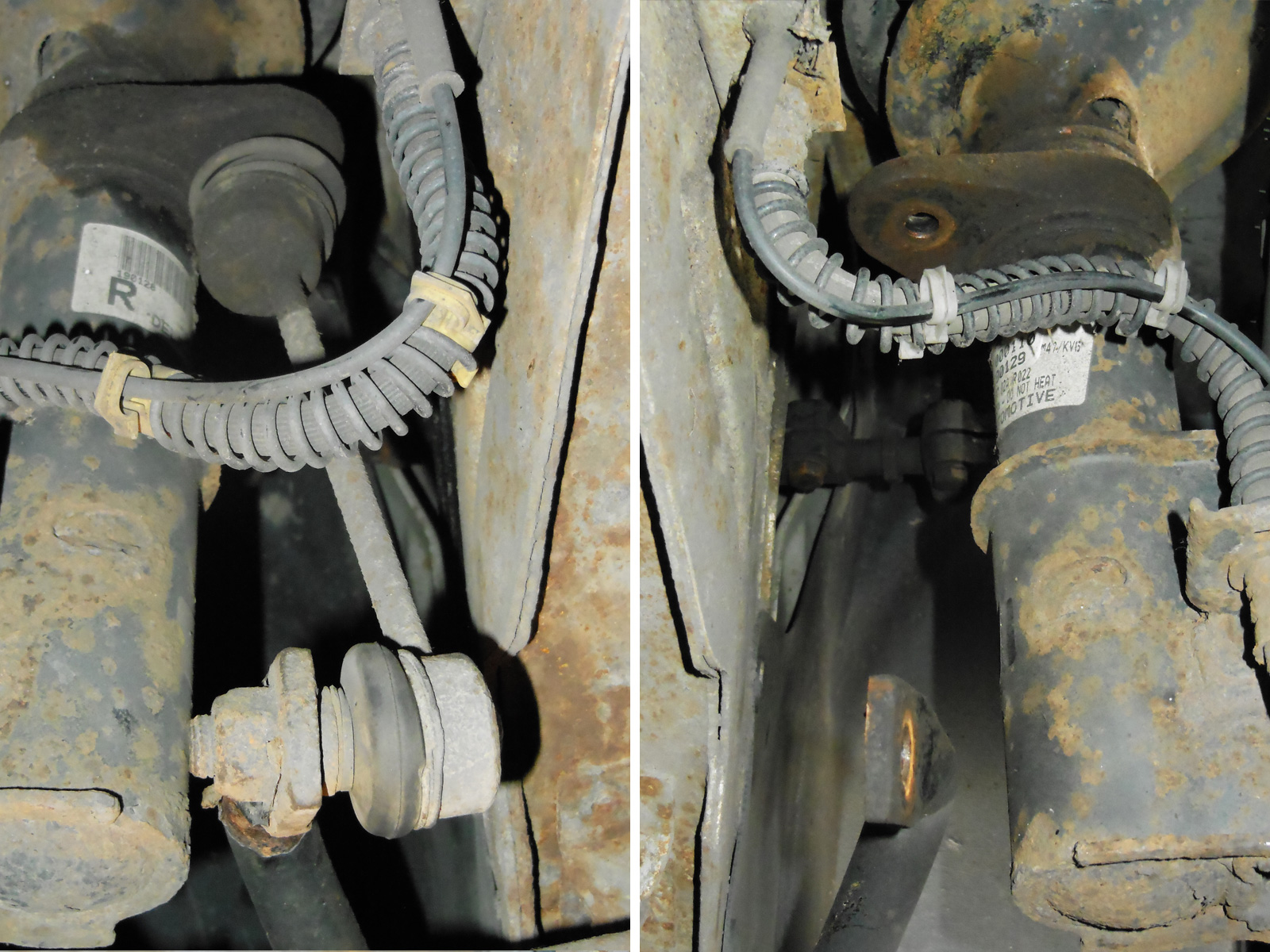

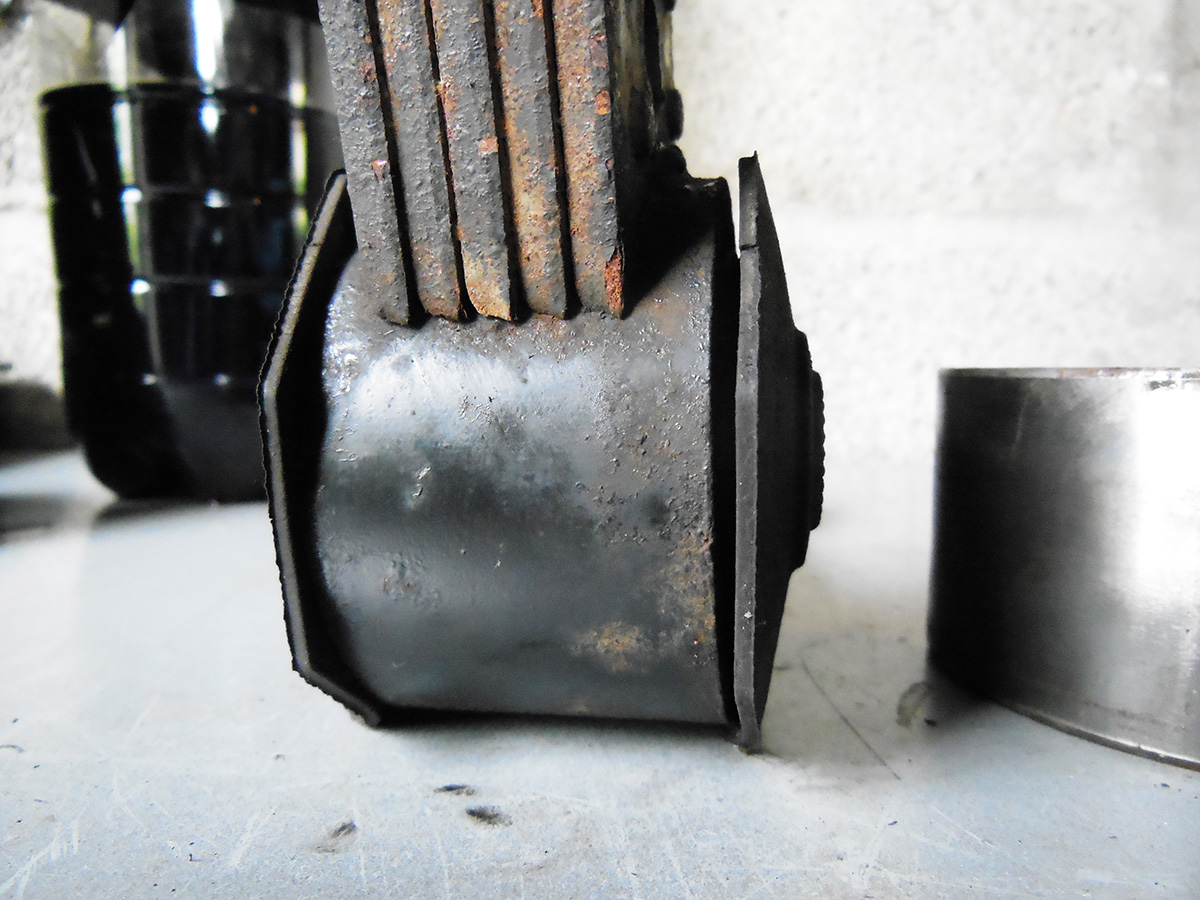

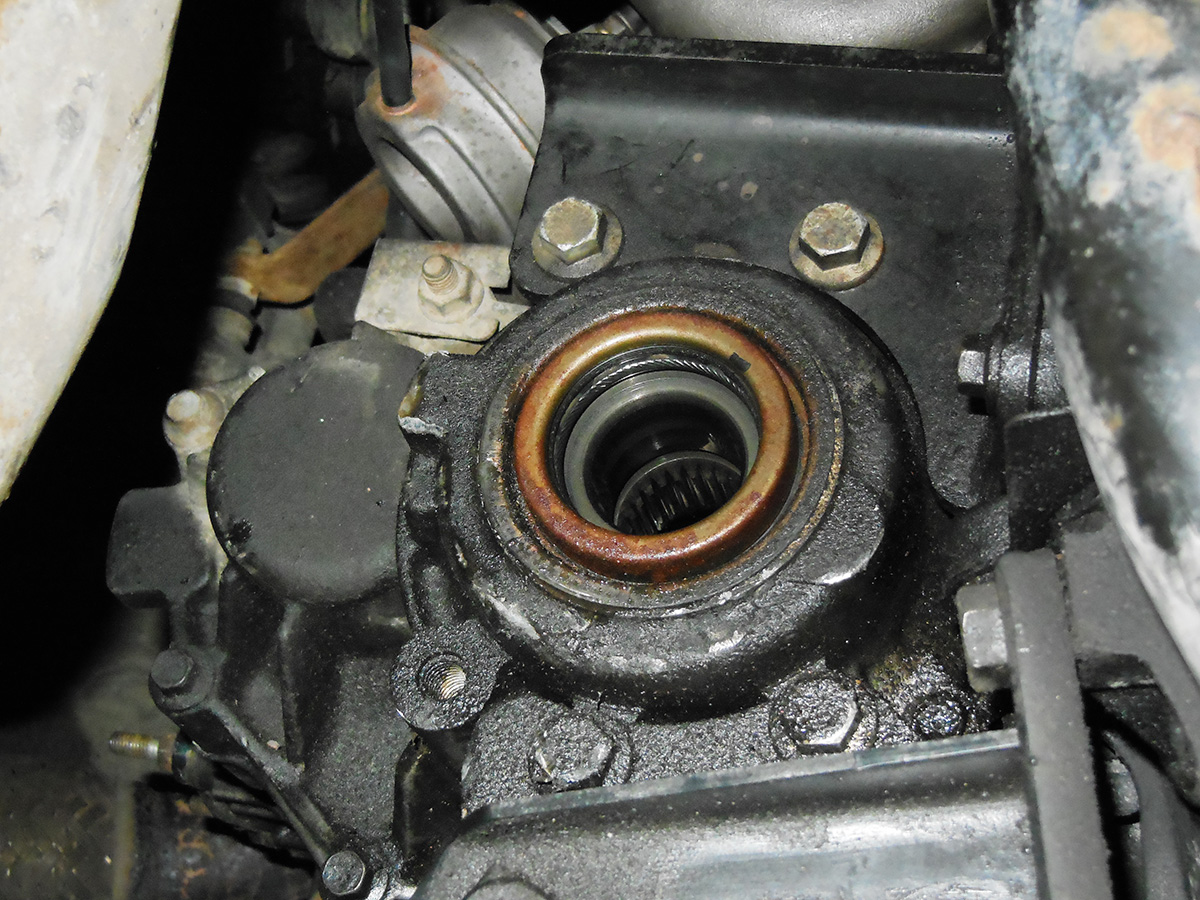

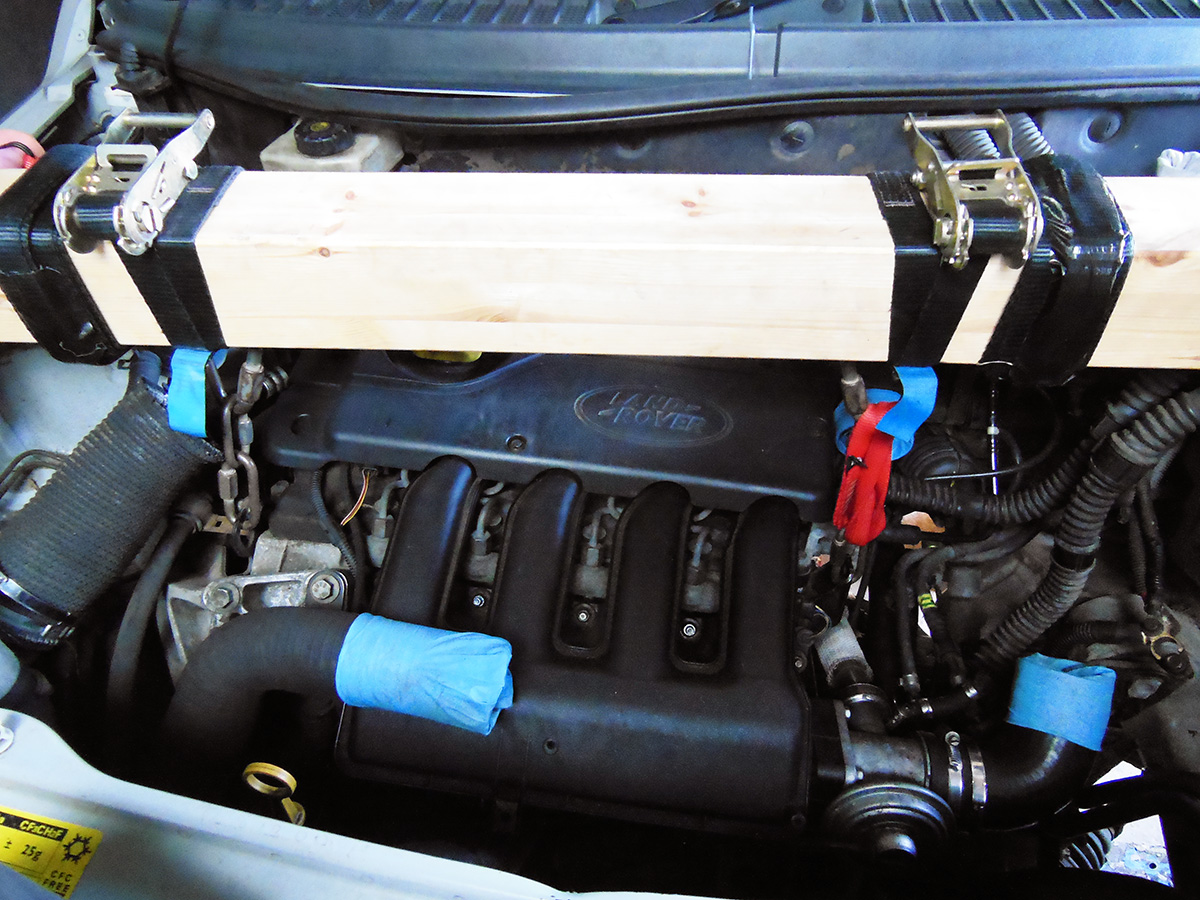

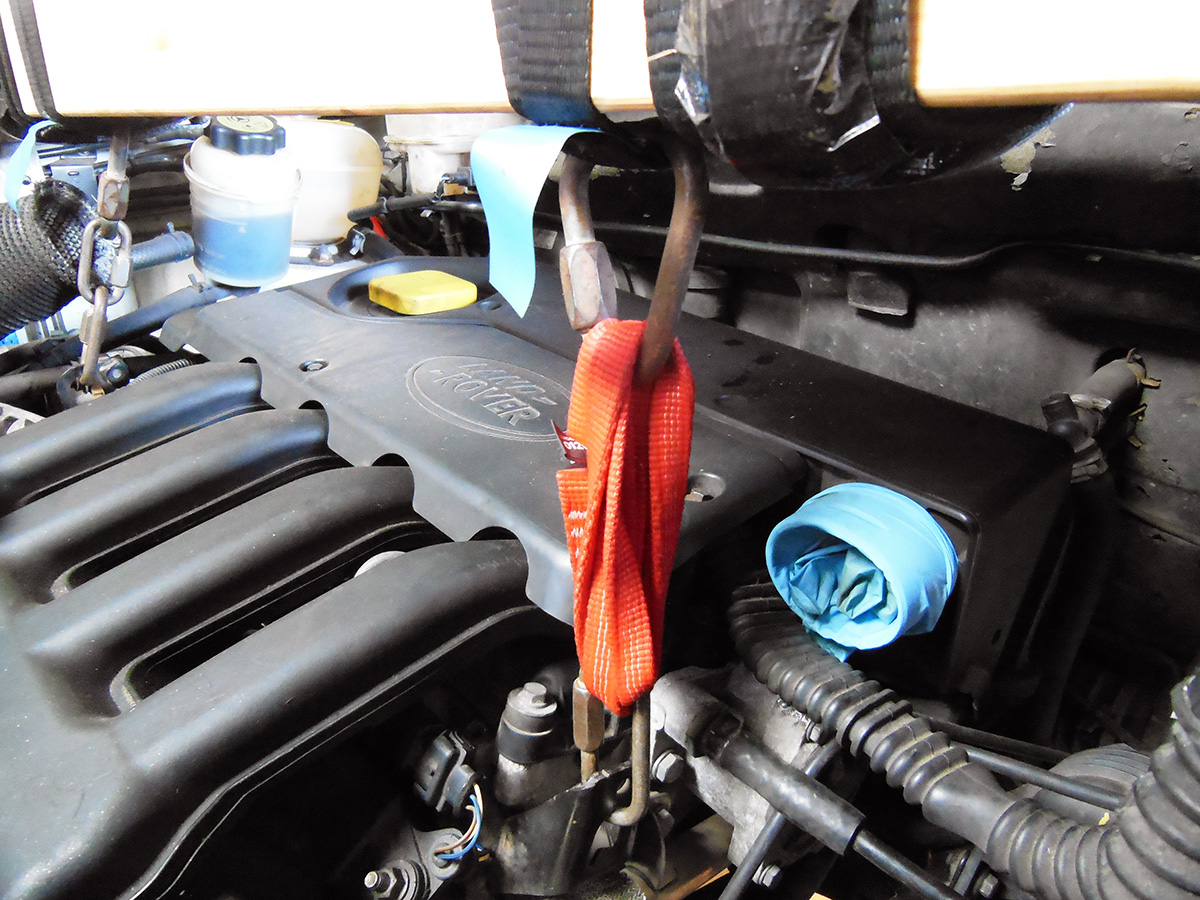

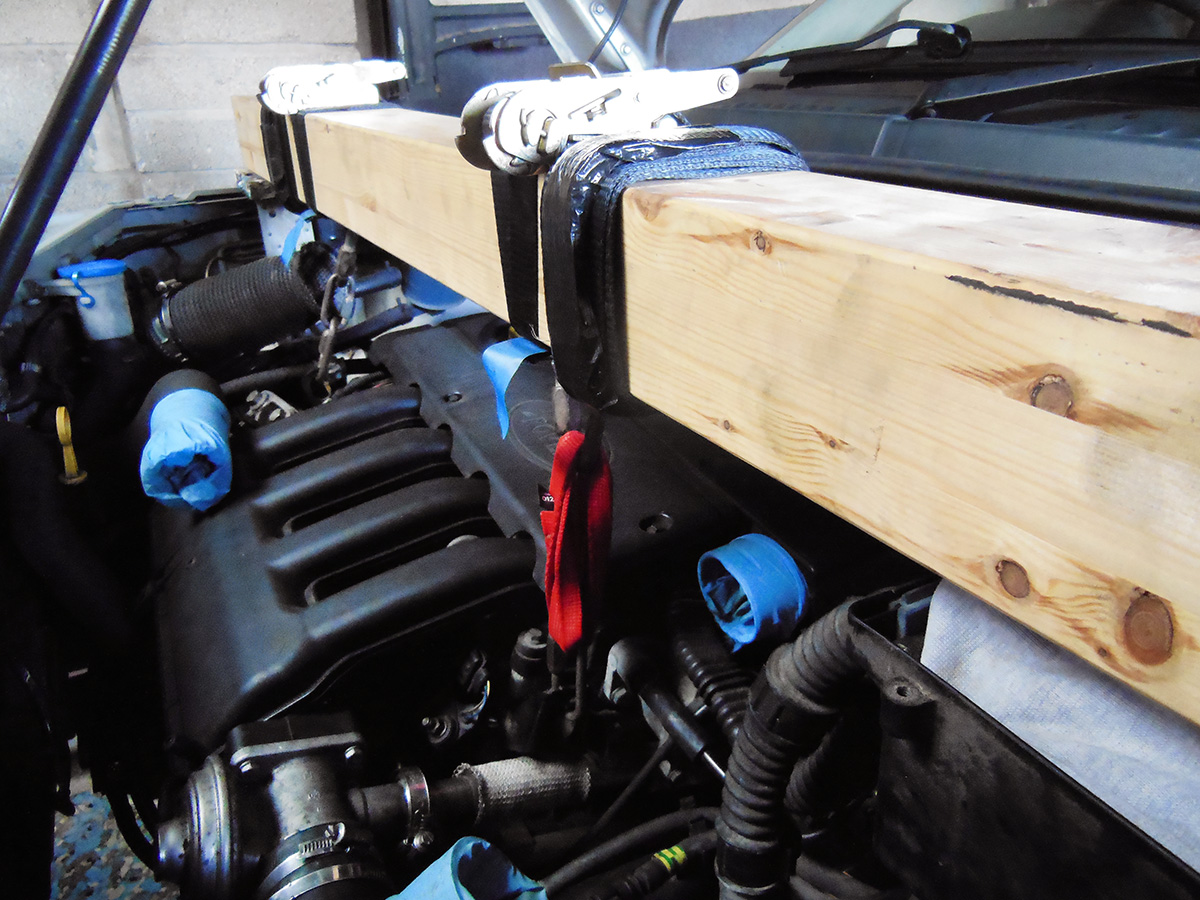

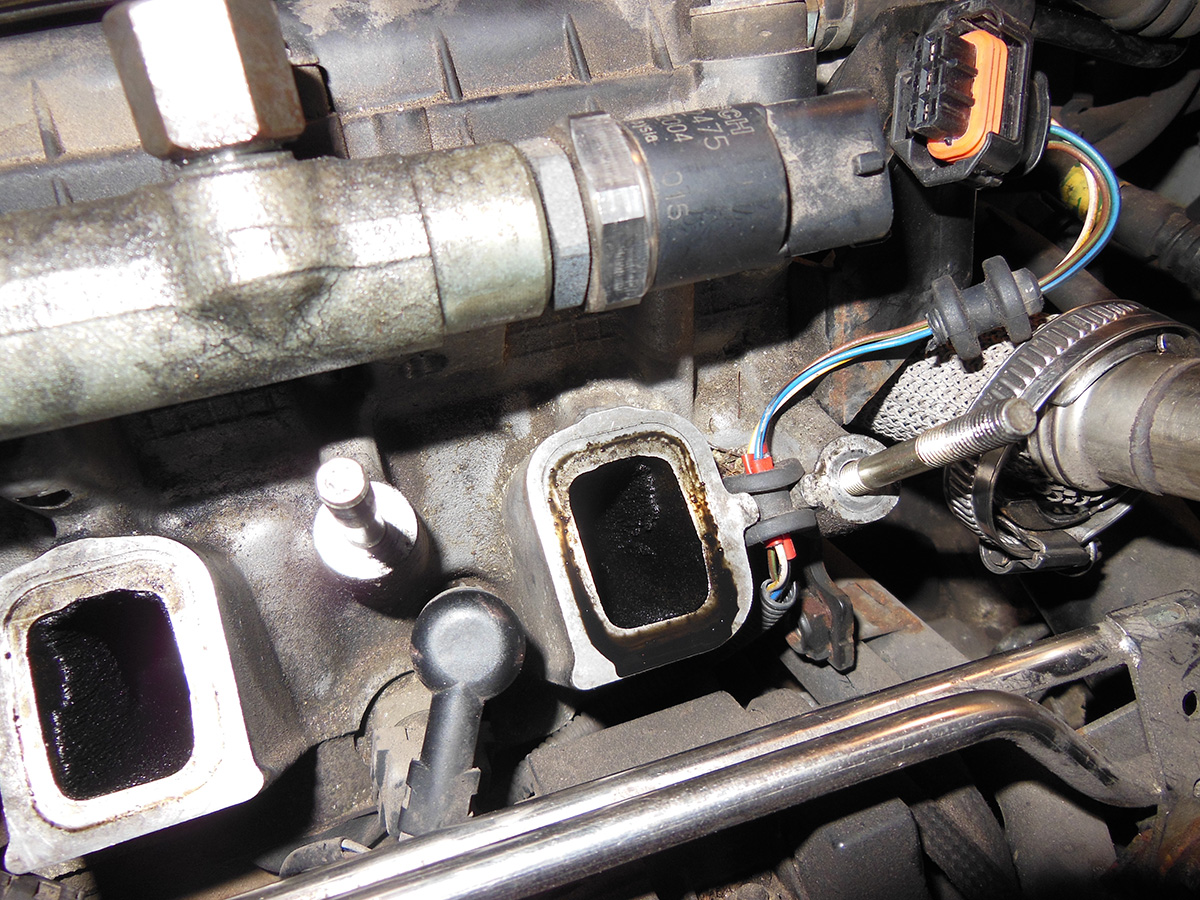

Decided to pull the alternator off and check the brushes. This is what I found...

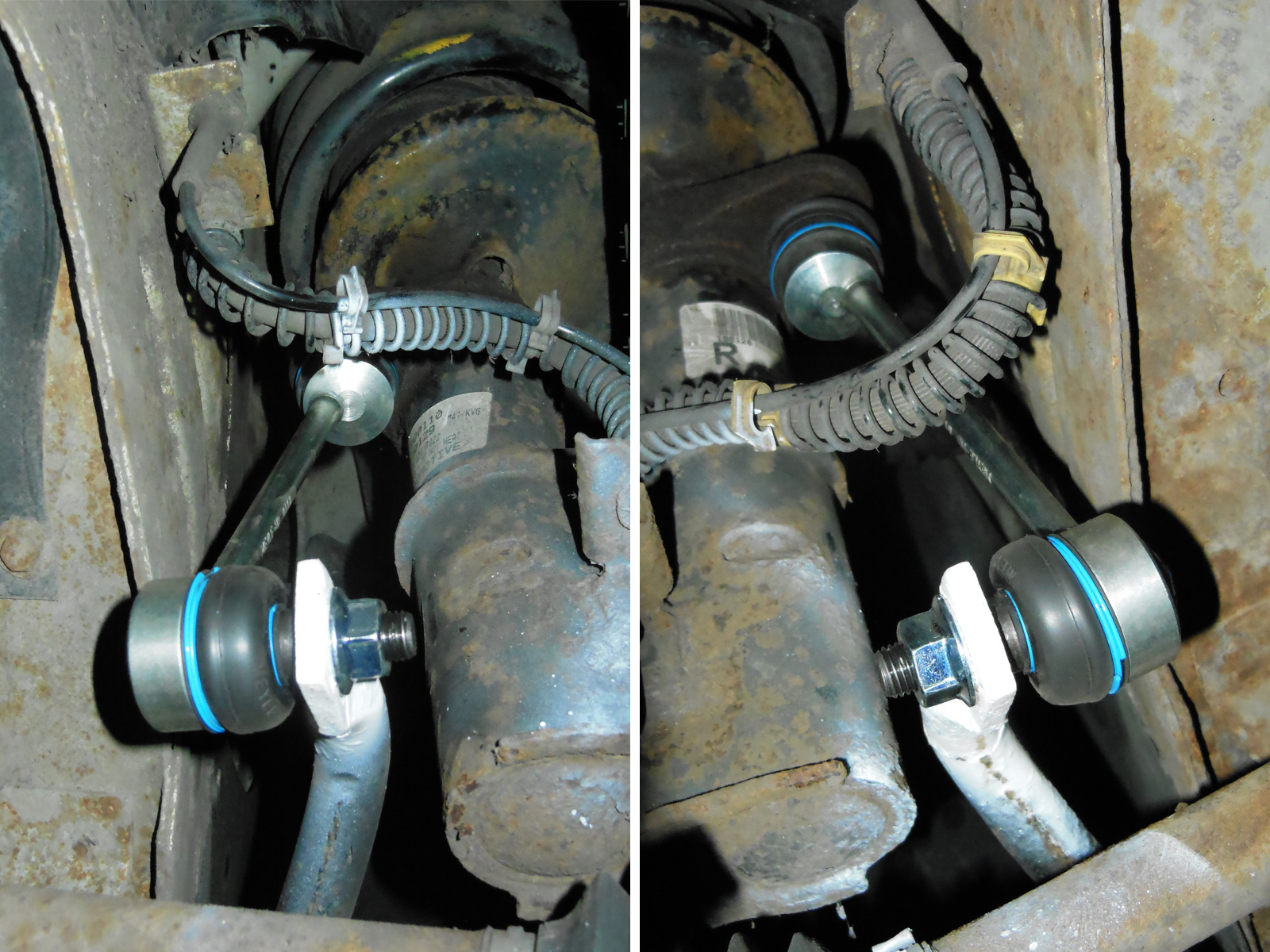

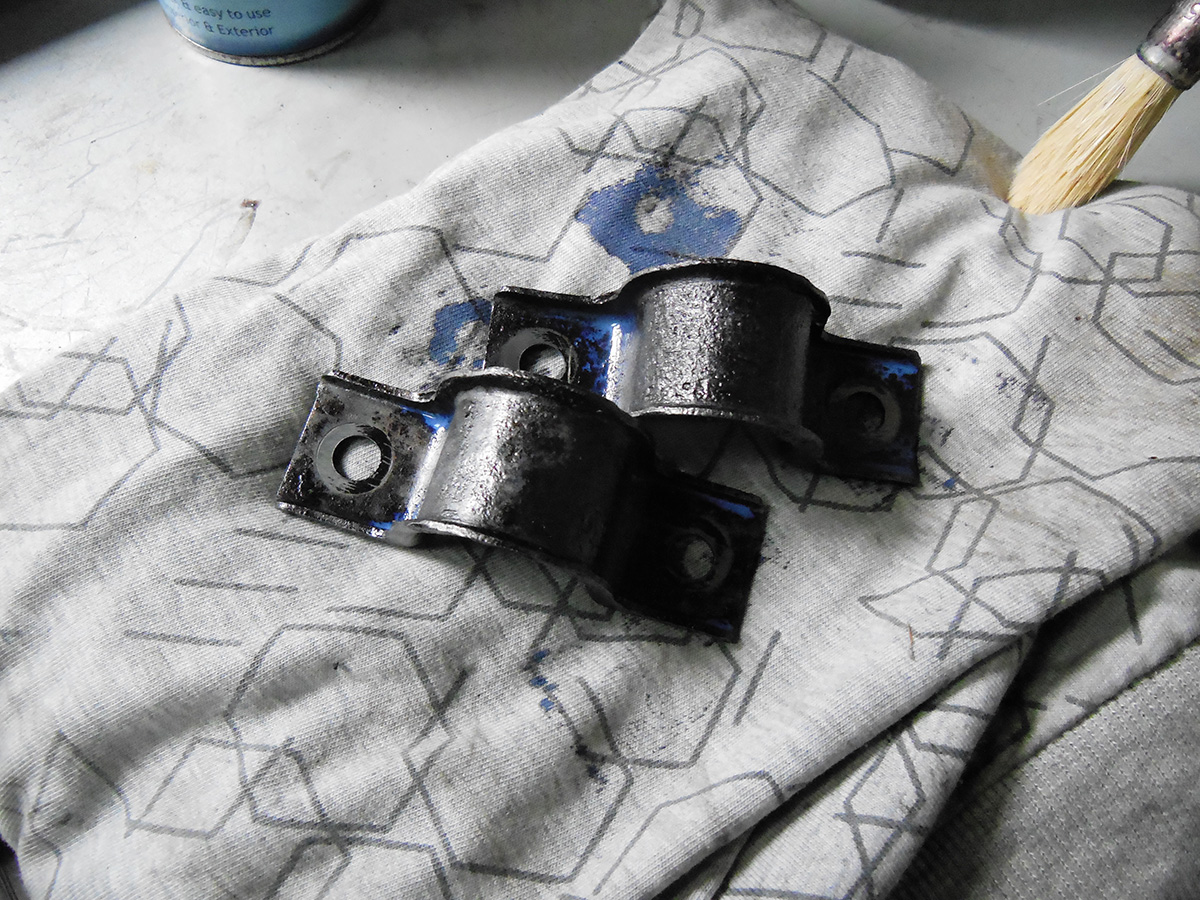

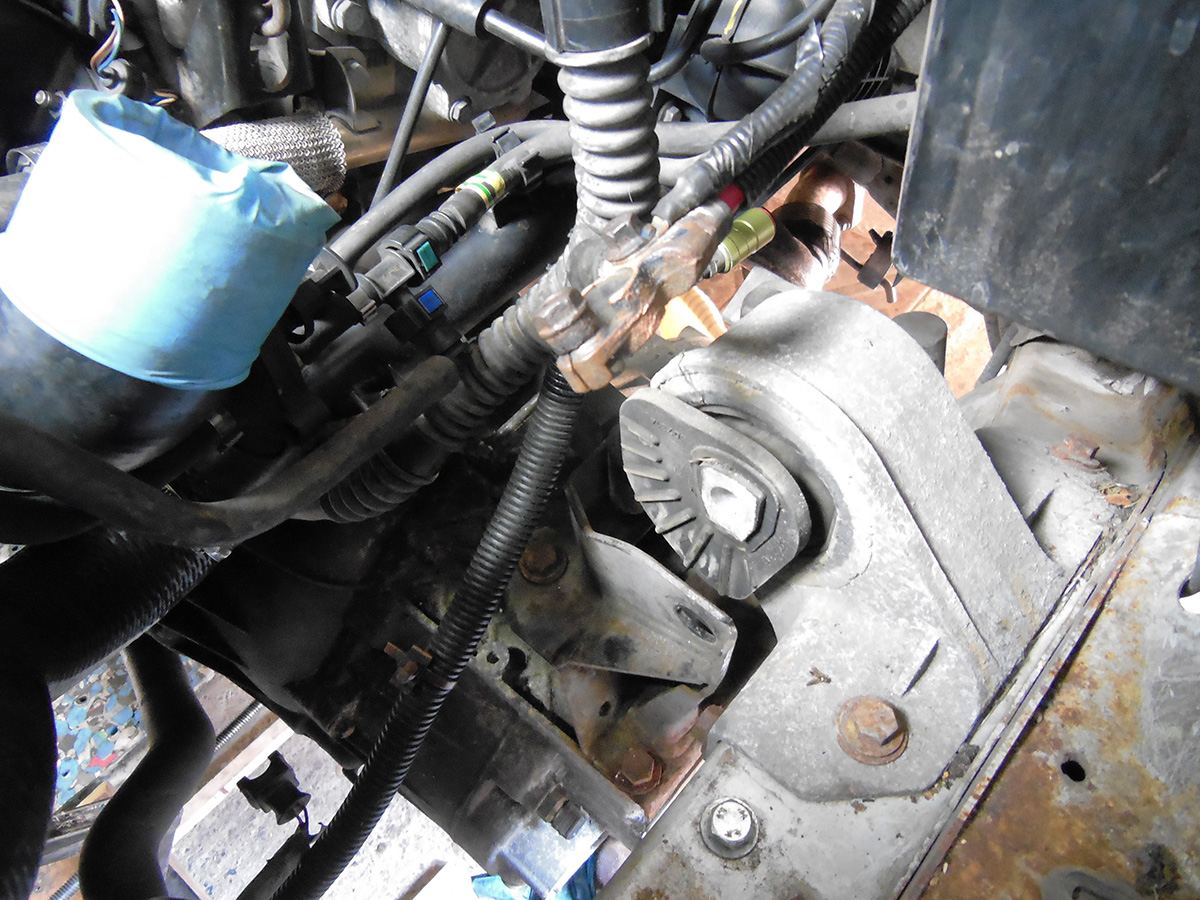

So it's out with the old...

...and in with the new.

Battery light now goes out and stays out

Eagle eyes may have spotted an alternator in the background of some of the earlier IRD photos. An intermittent battery light that I'd chalked up to 'atmospheric conditions' (see post 14) finally reared its head permenantly. I was able to temporarily recover it by hitting it with a hammer but that's not a long term solution

Decided to pull the alternator off and check the brushes. This is what I found...

So it's out with the old...

...and in with the new.

Battery light now goes out and stays out

Last edited: