That's incredible finish you achieve with the conditions that you are spraying in, I'm jealous as hell. I on the other hand can produce lovely runs consistently which I'm learning to accept as giving it some character. Well done and love the colour.Well, 3 weeks again I think, it's crap having a car project like this and no cash. While im waiting for the buds to open on the money tree I thought I'd do some paintwork, work has picked up so I've not had much time this last couple of weeks, today was busy also with forests second-biggest game of the season on TV so the Mrs' whole family was round consuming all the tea bags. A bit of a walk afterwards and got home thinking 'what to do?' It was about 5.30 and the air was still so I thought I'd laquer this lot. Now I've prepped it slowly over the last few weeks, got the rest of the basecoat on about 7 o clock yesterday morning, (to free up the day). For anybody that's particularly interested, these panels were rubbed to about 90% bare metal (180 grit) (so that when its scratched later in life it doesn't show up green), etch primed - 2 coats, 2k primed, guide coat then wet flat (600 grit), base coat with lrc378, 2k laquer - 2 1/2 coats except for the driver floor plate which had about 6/7 coats to use up what was left, to resist my feet rubbing through it.

The spray booth. The floor was dampened by the fact my house roof drains into it and it never seems dry. (Other brands of bottled gas available)

View attachment 98320

Hopefully take some time to wear through this.

View attachment 98321

Gearbox tunnel

View attachment 98322

Er...... This.

View attachment 98323

Rear floor.

View attachment 98324

Pits in rear floor. Not bothered.

View attachment 98325

I won't be doing anything else with this other than fitting it. I've used 2k because the cellulose I'd used on the outside is impossible to get a good finish with, and this is also harder wearing to stray tools/kids/boots (football and walking)/bikes etc. I wish I'd done the whole thing in 2k.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My First rebuild - 110 station wagon

- Thread starter Discokids

- Start date

This site contains affiliate links for which LandyZone may be compensated if you make a purchase.

Discokids

Well-Known Member

- Posts

- 3,160

- Location

- Derbyshire

Lol, that's why I left the dents in the bodywork, leave a bit of its character . If only those dents could tell stories. You will get there it just takes practice.

. If only those dents could tell stories. You will get there it just takes practice.

That's incredible finish you achieve with the conditions that you are spraying in, I'm jealous as hell. I on the other hand can produce lovely runs consistently which I'm learning to accept as giving it some character. Well done and love the colour.

Oh yeah,

Discokids

Well-Known Member

- Posts

- 3,160

- Location

- Derbyshire

Well, 9 weeks have passed since my last update. It started with me going in holiday and when I got back I'd kind of temporarily given up on it. Lack of money and time, plus going out on my mountain bike at every opportunity soon saw this on the back-burner again. Another sensible thing is - don't count the cost. I've kept a list of every penny I've spent, and I mean down to every last washer And rivet I've bought and its staggering. And I havent even got a galv chassis!!! Anyway, I'll publish that at the end. With a few days off work again I did eventually get back into it, that and the fact I've just sold a motorbike project I realised was never going to get finished (or even started, actually) which has given me some free cash. I decided that the headlining needed doing. One picture below of a miserable, fly-infested, mouldy and drooping headlining. Now, I got lucky and instead of buying 4 metres of material for £70 off ebay, I found somebody selling a roll end of 14 metres for £40 + delivery so snapped that up, so Ive a bit of spare for future projects. 4 cans of high temp spray adhesive and 3 hours later and here's my first attempt at a headlining.

Ok so it isn't brilliant but it's a damn site better than it was, even the Mrs was impressed (she actually said so!), there are a few creases and I even stood on one bit. I now just need some clips to hold it up, and sorry for the awful photographs, my phone has a bit of dust inside the camera lens which is blurring them all. Will sort this soon. And for the eagle-eyed, yes, that is a discovery hiding in the background. More on that soon.

Ok so it isn't brilliant but it's a damn site better than it was, even the Mrs was impressed (she actually said so!), there are a few creases and I even stood on one bit. I now just need some clips to hold it up, and sorry for the awful photographs, my phone has a bit of dust inside the camera lens which is blurring them all. Will sort this soon. And for the eagle-eyed, yes, that is a discovery hiding in the background. More on that soon.

Discokids

Well-Known Member

- Posts

- 3,160

- Location

- Derbyshire

So, I'm back at work full time now so progress is going to slow down a bit but thanks to the lighter evenings I can work away outside longer. I've turned my attention to the doors, as its a part of the project that requires little expense. I decided to separate tbe doors, I tried this before on a push button rear door and destroyed it because of the adhesive between skin and frame. Thankfully these 'proper' doors adhesive gave up long ago. Skin removed and started drilling out the spot welds.

The end of the upper crossmember thingy, not much left of it.

Surprisingly clean outer frame. This as you can see, has had another piece of steel wrapped around it for 30 years with almost no protection at all and is still solid.

Front edge proved a very brutal process.

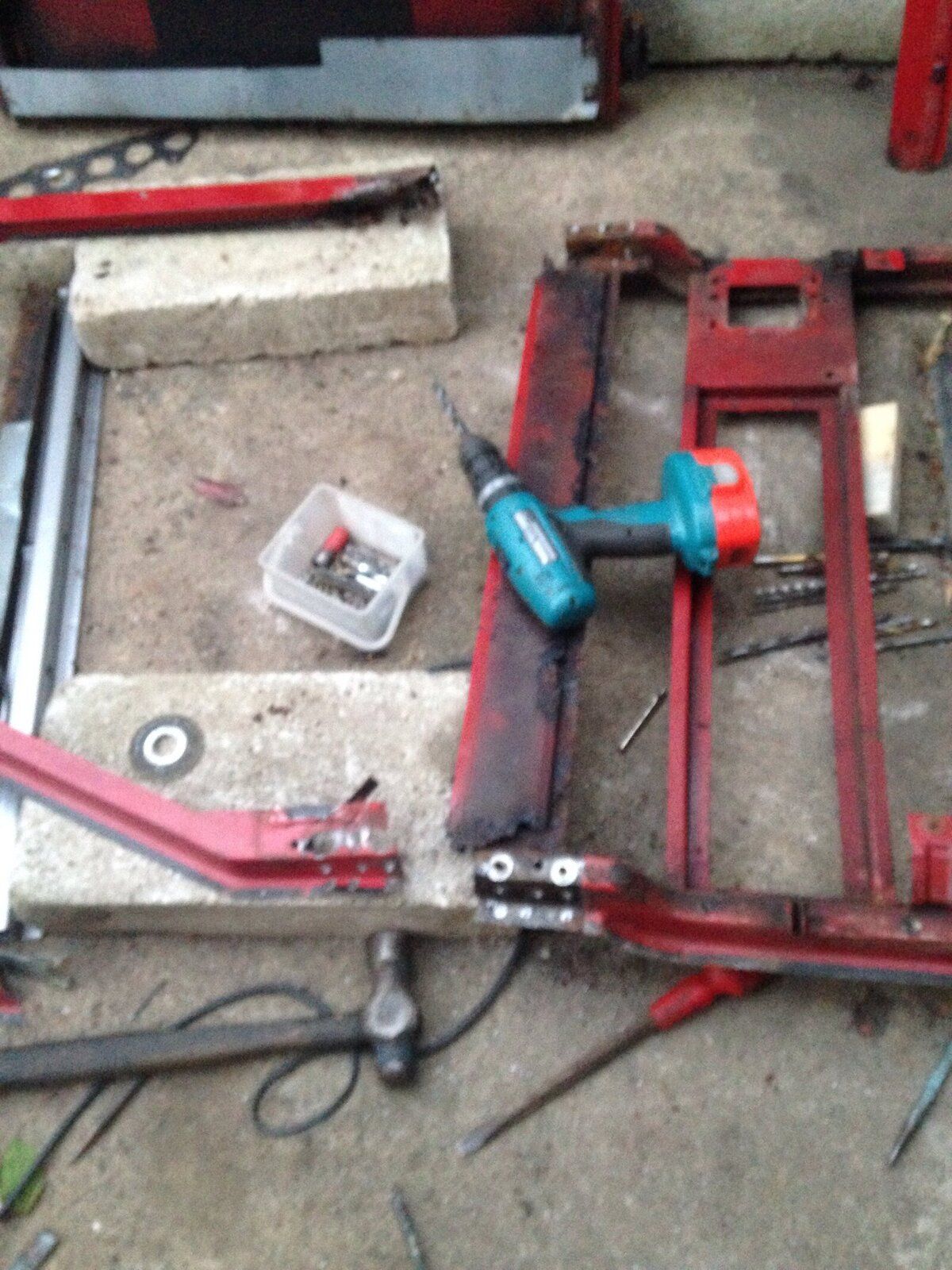

And the top separated from the bottom. Looking in before I was dreading trying to repair these. However, once it's apart and you can see and understand how it's fabricated it looks quite easy. I cannot find a supplier of that upper section though (the piece with the battery drill sat on it), I don't really want to repair this, and I have no facility to double bend the sheet steel as tight as this requires so that's going to take some thought.

The end of the upper crossmember thingy, not much left of it.

Surprisingly clean outer frame. This as you can see, has had another piece of steel wrapped around it for 30 years with almost no protection at all and is still solid.

Front edge proved a very brutal process.

And the top separated from the bottom. Looking in before I was dreading trying to repair these. However, once it's apart and you can see and understand how it's fabricated it looks quite easy. I cannot find a supplier of that upper section though (the piece with the battery drill sat on it), I don't really want to repair this, and I have no facility to double bend the sheet steel as tight as this requires so that's going to take some thought.

Alibro

Well-Known Member

- Posts

- 7,028

- Location

- Northern Ireland

You should have a look at this project for ideas.

These guys do some amazing fabrication.

These guys do some amazing fabrication.

I think I saw that part on yrm, item 236. I will be watching how you get on as my doors are a mess.looking forward to see how you get on.So, I'm back at work full time now so progress is going to slow down a bit but thanks to the lighter evenings I can work away outside longer. I've turned my attention to the doors, as its a part of the project that requires little expense. I decided to separate tbe doors, I tried this before on a push button rear door and destroyed it because of the adhesive between skin and frame. Thankfully these 'proper' doors adhesive gave up long ago. Skin removed and started drilling out the spot welds.

View attachment 101959

The end of the upper crossmember thingy, not much left of it.

View attachment 101960

Surprisingly clean outer frame. This as you can see, has had another piece of steel wrapped around it for 30 years with almost no protection at all and is still solid.

View attachment 101961

Front edge proved a very brutal process.

View attachment 101962

And the top separated from the bottom. Looking in before I was dreading trying to repair these. However, once it's apart and you can see and understand how it's fabricated it looks quite easy. I cannot find a supplier of that upper section though (the piece with the battery drill sat on it), I don't really want to repair this, and I have no facility to double bend the sheet steel as tight as this requires so that's going to take some thought.

View attachment 101963

Last edited:

Discokids

Well-Known Member

- Posts

- 3,160

- Location

- Derbyshire

Ouch, £29 x4 + VAT. I, like many, can vouch for the absolute top-notch quality of YRM stuff but that's a lot of beer tokens. I didn't realise they even sold it tbh.

Alibro

Well-Known Member

- Posts

- 7,028

- Location

- Northern Ireland

Doesn't look like it includes the end bits either. You can make those yourself can't you?Ouch, £29 x4 + VAT. I, like many, can vouch for the absolute top-notch quality of YRM stuff but that's a lot of beer tokens. I didn't realise they even sold it tbh.

Discokids

Well-Known Member

- Posts

- 3,160

- Location

- Derbyshire

I've already done it, there isn't really an end as such, looking at the very small amount of metal that's left it looks as though it's welded straight to the inner of the frame. It's just that on all 7 doors I have here, they've all rotten out so its a common rot area and hard for me to know exactly. Will post pics of progress tomorrow.

Alibro

Well-Known Member

- Posts

- 7,028

- Location

- Northern Ireland

Great, keep em coming, loving this thread.

Discokids

Well-Known Member

- Posts

- 3,160

- Location

- Derbyshire

You should have a look at this project for ideas.

These guys do some amazing fabrication.

That's brilliant. I love the jig, and the scarecrow, good stuff. Makes my welding look like my 5 yo daughter has done it.

Alibro

Well-Known Member

- Posts

- 7,028

- Location

- Northern Ireland

That was over two years ago, you've a lot more episodes to watch, it gets better.

It makes my welding look like I did it blindfolded with both hands tied behind my back.

It makes my welding look like I did it blindfolded with both hands tied behind my back.

Discokids

Well-Known Member

- Posts

- 3,160

- Location

- Derbyshire

Where can I find more of those videos? It is certainly inspirational. As well as doing this ive got a disco awaiting either a light restoration or scrapping, with plenty of welding needed, but im actually considering that and this 110 just mere practice for the day I rebuild a Range Rover classic.

Alibro

Well-Known Member

- Posts

- 7,028

- Location

- Northern Ireland

That was episode one, If you can't see other episodes do a search in youtube for "project binky episode 2/3/4" etc.

Discokids

Well-Known Member

- Posts

- 3,160

- Location

- Derbyshire

Never thought of that. Technology eh?

- Posts

- 11,020

- Location

- North of the Wall

They're well worth watching.

Discokids

Well-Known Member

- Posts

- 3,160

- Location

- Derbyshire

Well me poor 110 has now been neglected for the majority of the year since I went away at Easter. I've tried to do little bits and bobs but with lack of time, money and enthusiasm it does get difficult. Lack of time caused by having a job, kids, holidays etc, lack of money caused by having kids and holidays, lack of enthusiasm caused by, well, the paint. As both of you that read this thread know, I've done it in cellulose. I've been painting stuff for over 15 years and actually did this as an apprentice and always used 2k but thought it would be wrong for this vehicle so used cellulose instead. Every time I look at it it scratches. Or fades. Bird droppings eat through it. It's driven me to the point of seriously considering giving up. But then I had a better idea, spend a few days sanding off all the celly and starting again. Quite extreme but the only way forward it seemed. So far, the windscreen frame, rear tub, bulkhead and b pillars have all had it, only a few bits remain to be painted then it's onto the doors which weren't done yet anyway. Pics will be posted tomorrow but this has rekindled the passion and I'm back on track. Being flat out at work all summer has taken care of the cash flow side of things too so my priority is to get it sealed up before winter sets in so I can focus on the bit im most looking forward to - wiring it up!

And I seriously hope I never see another tin of cellulose paint ever again.

And I seriously hope I never see another tin of cellulose paint ever again.

Discokids

Well-Known Member

- Posts

- 3,160

- Location

- Derbyshire

Pics as promised.

Right hand rear rubbed down and fresh primer, just wet-flatted (600) note the b pillar also.

Painted and lacquered, then wet-flatted (1500) and buffed with G3.

Gun fresh laquer on the bulkhead. Think I'll leave as is.

Left rear quarter rubbed down (180 dry then 320 wet) ready for new primer.

Right hand rear rubbed down and fresh primer, just wet-flatted (600) note the b pillar also.

Painted and lacquered, then wet-flatted (1500) and buffed with G3.

Gun fresh laquer on the bulkhead. Think I'll leave as is.

Left rear quarter rubbed down (180 dry then 320 wet) ready for new primer.

Similar threads

- Replies

- 1

- Views

- 511

- Replies

- 15

- Views

- 1K