TheMegaMan

Well-Known Member

- Posts

- 516

- Location

- Cambridge

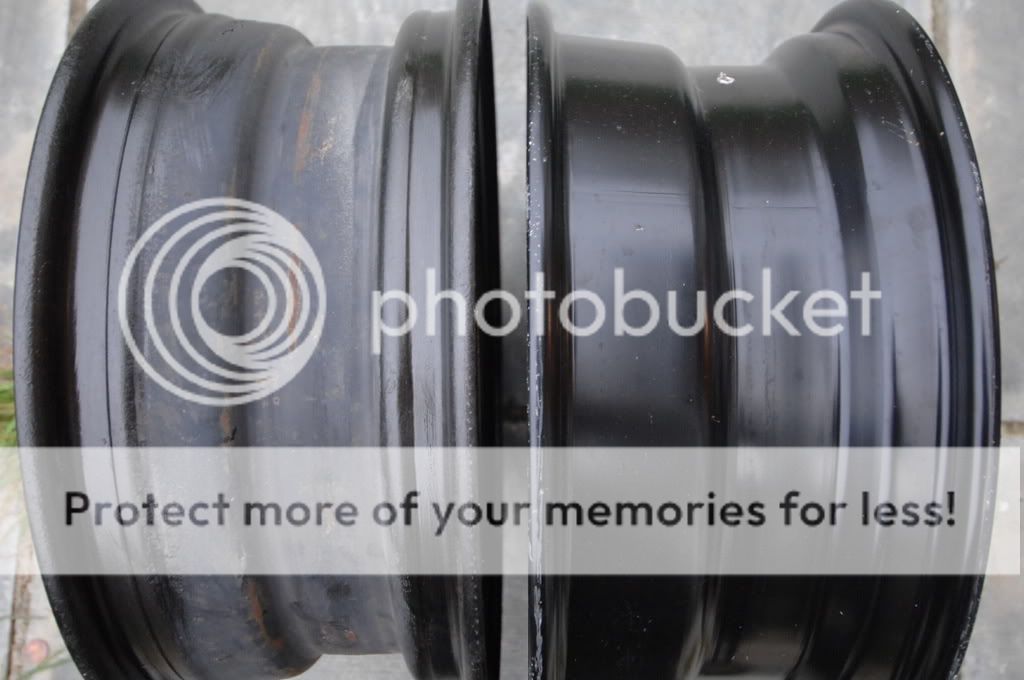

My S3 rebuild is still slowly progressing, but I need 4 new tyres. The tyres are here, and I'm going to fit tubes to them all (I don't think they are all tubed at the moment, but I'm pretty sure the rims aren't tubeless, so I'm going to play safe).

The issue I have is that the only vehicle I have that would allow me to take the tyres and wheels to the local tyre place for fitting, is the Landy...which won't be mobile until I've got the tyres mounted for it!

Someone on here (Col?) commented that being able to fit your own tyres was useful, so I thought I'd give that a go!

I've got some long tyre levers and ordered a bead breaker, so I should be able to get the old knackered tyres off, and hopefully fit the new ones, too. But balancing will still be a issue.

I could just drive to the tyre place and take the wheels off when I'm there, but I've found https://www.ebay.co.uk/itm/303498150121 on ebay, and wondering if I can actually do everything myself. Problem is (I think) that it'll only work on rims with a hole up to 4" diameter, and I think the Landy wheels are around 4.5"-5". And if the wheel isn't properly centred, balancing won't be accurtate.

Has anyone else done their own wheel balancing? Any tricks to make it easy? Can it be done easily with cost-effective equipment?

The issue I have is that the only vehicle I have that would allow me to take the tyres and wheels to the local tyre place for fitting, is the Landy...which won't be mobile until I've got the tyres mounted for it!

Someone on here (Col?) commented that being able to fit your own tyres was useful, so I thought I'd give that a go!

I've got some long tyre levers and ordered a bead breaker, so I should be able to get the old knackered tyres off, and hopefully fit the new ones, too. But balancing will still be a issue.

I could just drive to the tyre place and take the wheels off when I'm there, but I've found https://www.ebay.co.uk/itm/303498150121 on ebay, and wondering if I can actually do everything myself. Problem is (I think) that it'll only work on rims with a hole up to 4" diameter, and I think the Landy wheels are around 4.5"-5". And if the wheel isn't properly centred, balancing won't be accurtate.

Has anyone else done their own wheel balancing? Any tricks to make it easy? Can it be done easily with cost-effective equipment?