Also got the welder working with some trial and error and picked up some sheet. The penny really dropped. I was sat looking at the spool of wire and realised it was either stainless or no gas. The tip was also slightly damaged on closer inspection so it kept birdnesting. Went to screfix and ordered a roll if mild steel and a pack of tips to suit. Glad to know it' the monkey working it and not the welder that's broken lol

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Steep learning curve

- Thread starter resto_d1

- Start date

This site contains affiliate links for which LandyZone may be compensated if you make a purchase.

- Posts

- 9,105

- Location

- Roaming the UK on assignments

Like your thinking there.

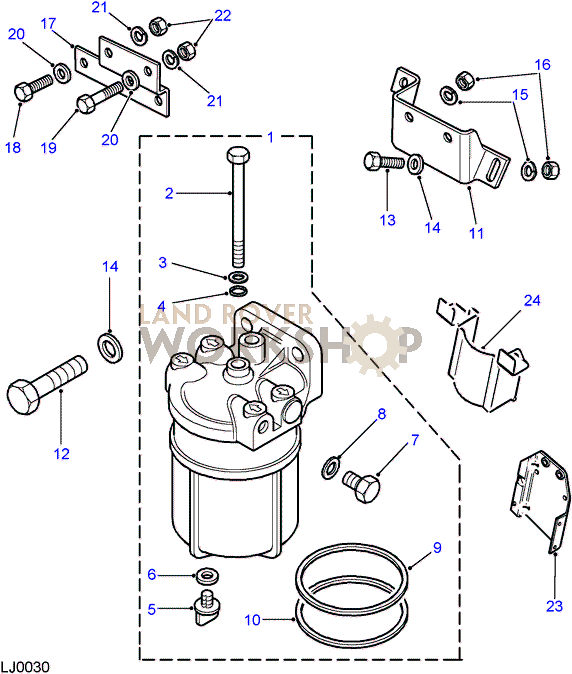

While its easy to get at you should drop your sedimenter bowl and clean it out, a whoooore of a job with that floor back in

While its easy to get at you should drop your sedimenter bowl and clean it out, a whoooore of a job with that floor back in

Like your thinking there.

While its easy to get at you should drop your sedimenter bowl and clean it out, a whoooore of a job with that floor back in

Brushed back and gave all visible bolts and nuts a spray of wd whilst floors out. Is that sedimentor a consumable I.e service item? Also, I'm thinking now is time to drop the tank. Depressurise by pulling fuel relays and cranking then remove lines from sender? I'll have to try and drain it Scouse style first though!

- Posts

- 9,105

- Location

- Roaming the UK on assignments

No relays to pull, 300Tdi only has a mechanical lift pump on the engine to draw fuel from the tank, sedimenter is just an open bowl that allows rubbish drawn to fall out of the fuel, drop the bowl off it via the 11mm through bolt and drain it out an wipe clean.

Easiest thing to do is pull the sender out the top of the tank an syphon it out with a length of hose.

Easiest thing to do is pull the sender out the top of the tank an syphon it out with a length of hose.

- Posts

- 9,105

- Location

- Roaming the UK on assignments

Only the long bolt through the middle of it.

Dirty jobs. Had to get changed half way through as was stinking of diesel. Tried to drain tank using two hoses but reverted to the old school and sipped a bit of diesel. Tow bar off, tank cradle off, tank dropped. Only had to look at the strap. Chassis prep a lot easier when you can put your body behind the drill. Second coat of deox gel on but that' first coat is some places. Wanted to get painting this weekend but no point rushing!

- Posts

- 9,105

- Location

- Roaming the UK on assignments

See, told you that sedimentor was a good start whilst the floor was out

Nice whiteboard, the list seems long but a lot of that goes quick, there are a number of 5 minute jobs on there that will whizz right off in a decent day of spannering.

Nice whiteboard, the list seems long but a lot of that goes quick, there are a number of 5 minute jobs on there that will whizz right off in a decent day of spannering.

- Posts

- 9,105

- Location

- Roaming the UK on assignments

You missed off the cam belt.

Cambelt is on my phone lol don't know why it' not on board. Am I right in saying I need an updated kit with a lipped pulley? Yeah a lot of it is just chilled out spannering which I enjoy. Despite the current filthy tasks I'm enjoying it. I like how everything is just bolted with no nonsense. Makes it easier to strip down. The b pillars are a worry and also the horizontal gusset coming off them to the boot. I' thinking it will be repair b first with rear quarters removed then work back towards boot. I also have a dead rigger and a chunk or chassis where the rear of the two main boot beams sit. You know the ones with the rectangle plates on top

- Posts

- 9,105

- Location

- Roaming the UK on assignments

Cambelt is on my phone lol don't know why it' not on board. Am I right in saying I need an updated kit with a lipped pulley? Yeah a lot of it is just chilled out spannering which I enjoy. Despite the current filthy tasks I'm enjoying it. I like how everything is just bolted with no nonsense. Makes it easier to strip down. The b pillars are a worry and also the horizontal gusset coming off them to the boot. I' thinking it will be repair b first with rear quarters removed then work back towards boot. I also have a dead rigger and a chunk or chassis where the rear of the two main boot beams sit. You know the ones with the rectangle plates on top

300Tdi, pop the cover off and see if you already have the updated kit, the last one rolled off the production line over 20 years ago, should have been done by now.

The welding is no stress, lots of 2mm plate and blaze away, removing the rear quarters is a good shout, I'm reluctant as mine is a 3 door and it's a lot of panel to remove but on a 5 door it's a doddle.

Oh and the sandwiched plate welded to the cross beam of the chassis where the tank guard bolts to needs chopping and welding. I will start putting in some practice tomorrow night with the new reel of wire. Tips I bought were m8 and I needed m6. I'l eBay some more!

300Tdi, pop the cover off and see if you already have the updated kit, the last one rolled off the production line over 20 years ago, should have been done by now.

The welding is no stress, lots of 2mm plate and blaze away, removing the rear quarters is a good shout, I'm reluctant as mine is a 3 door and it's a lot of panel to remove but on a 5 door it's a doddle.

Looks like it's a matter of undoing a set of bolts, drilling 3 spots out then Stanley blade down the mastik. The flat plate isn't such a worry it's tying these bits in that may take a bit of fettling

- Posts

- 9,105

- Location

- Roaming the UK on assignments

Looks like it's a matter of undoing a set of bolts, drilling 3 spots out then Stanley blade down the mastik. The flat plate isn't such a worry it's tying these bits in that may take a bit of fettling View attachment 149401 View attachment 149402

Easy peasy, 2mm plate over the arch and then cut and replace bottom of the pillar with 2mm plate sections seam welded up, quick tip, leave a hole in one corner for the excess waxing to escape when you blaze it through with Dinitrol cavity wax inside the pillar.

That roof section looks like an easy cut and shut with plating and a good dousing with cavity wax will see it good for another decade.

- Posts

- 83,310

- Location

- Embasinga stocæ

i like the confidence

Similar threads

- Replies

- 1

- Views

- 651

- Replies

- 5

- Views

- 522