Wagon Loon

Well-Known Member

- Posts

- 573

- Location

- Aberdeen

Hi GSF 109,

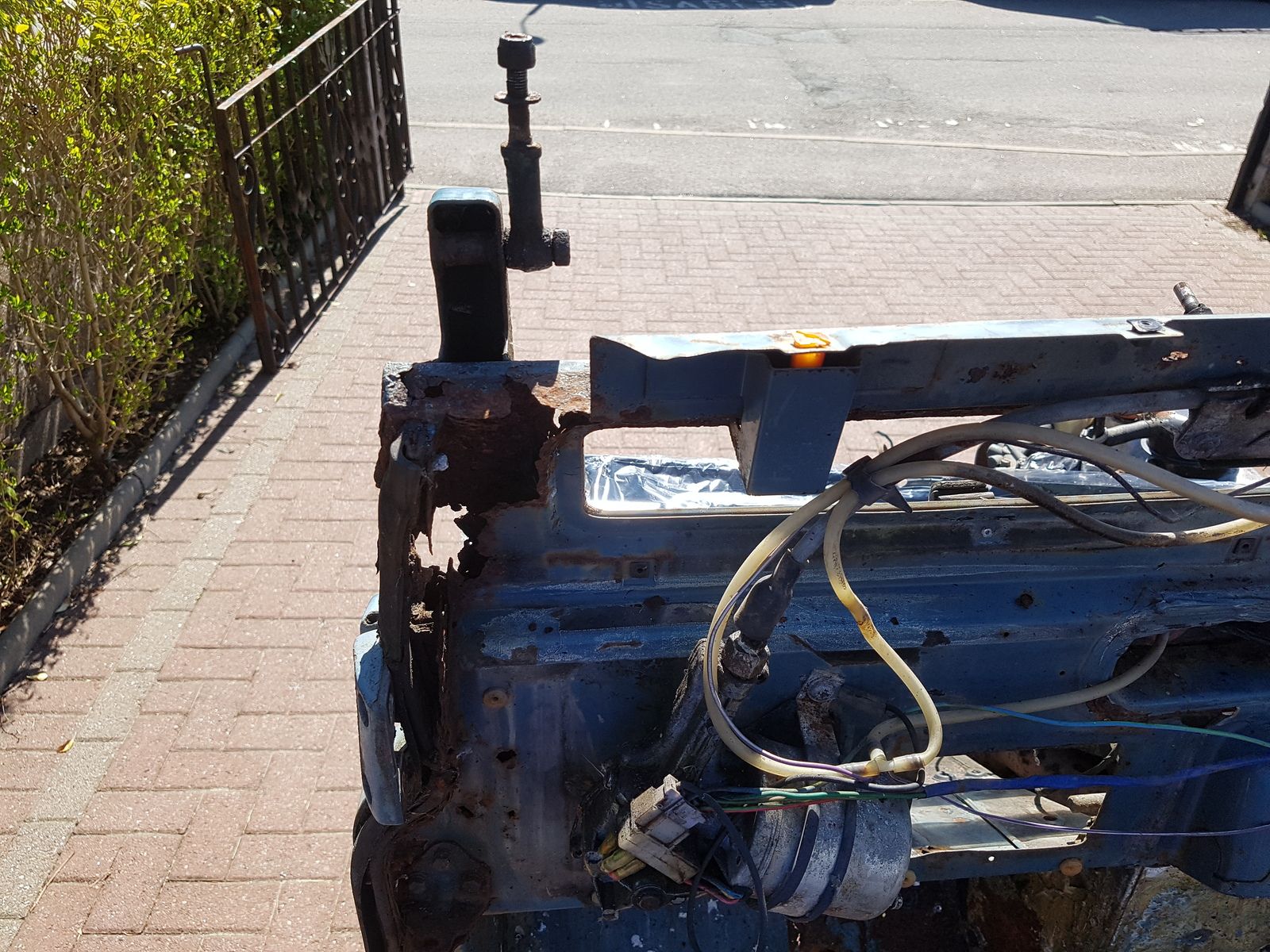

I too have taken on an 82 series 3 wagon and have started on my bulkhead, which is in poor condition, but slowly the years are being rolled back.

Yes your garage looks very big and useful.

I got the complete b and c pillar and sills as complete galvanised units from Ronnie Junior YRM. They were not cheap, but I figure they will save me days of trying to get all the parts in the exact right place and angle before welding; so should be worth it.

How did you do the stiffener in the top of your A pillar please. Mine completely disintegrated

lol

lol

So I have been making those repair panels I could not buy

I too have taken on an 82 series 3 wagon and have started on my bulkhead, which is in poor condition, but slowly the years are being rolled back.

Yes your garage looks very big and useful.

I got the complete b and c pillar and sills as complete galvanised units from Ronnie Junior YRM. They were not cheap, but I figure they will save me days of trying to get all the parts in the exact right place and angle before welding; so should be worth it.

How did you do the stiffener in the top of your A pillar please. Mine completely disintegrated

So I have been making those repair panels I could not buy