GSF 109

Well-Known Member

- Posts

- 813

- Location

- Scotlandshire

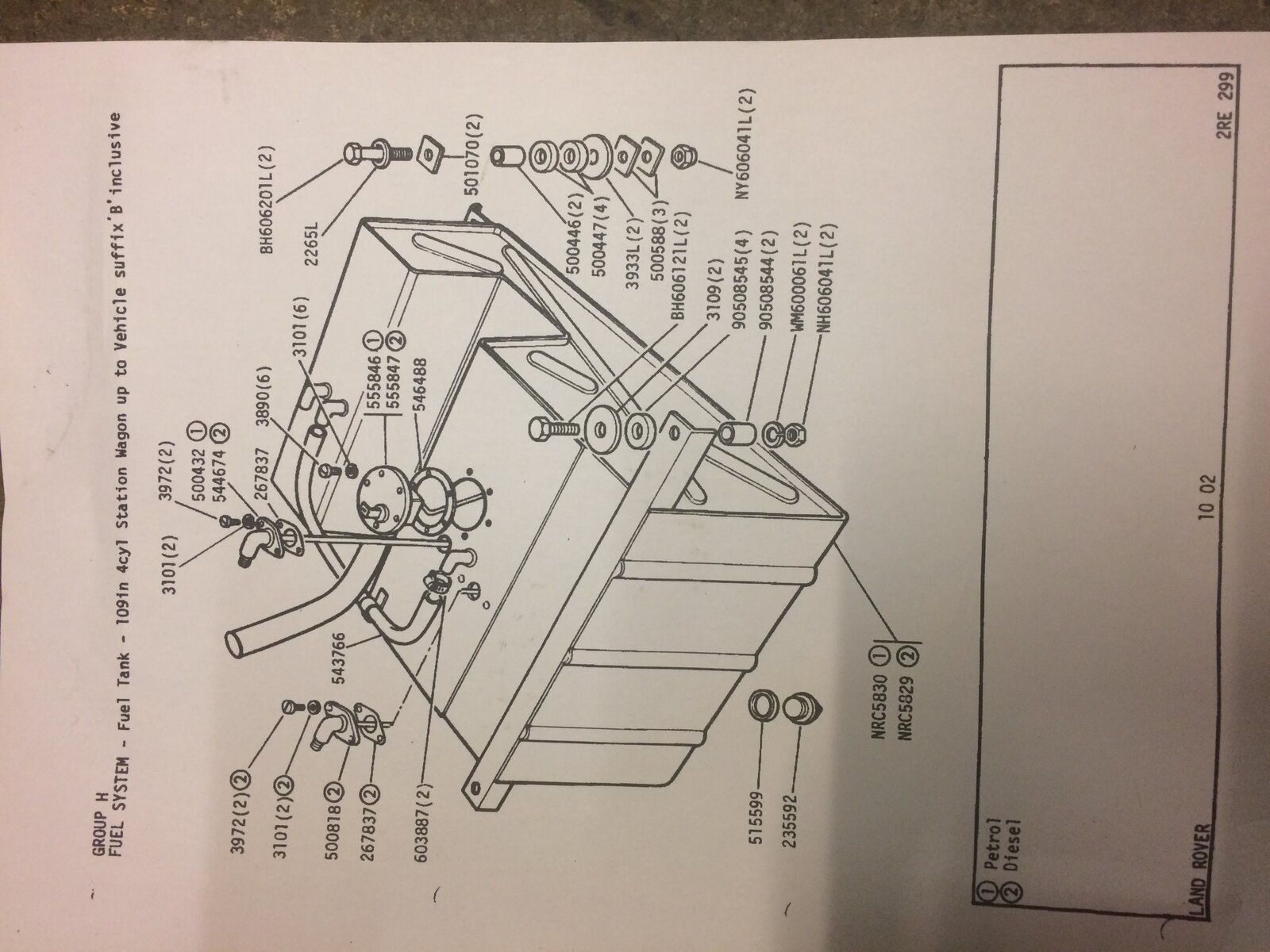

Ok, so I used the parts drawing for the fuel tank to see what it should look like as mine were cobbled together with threaded rod and non original bushes. It thought it would be a simple assembly job...... no chance!!!

The drawing was completely wrong. It showed spring washers when they should be flaunt and plain nuts when they should be nyloc ... Anyway, I managed to get the front ones to fit but the rear holes in the crossmember were completely in the wrong place! So, I drilled the holes again, reprotected them and assembled using plenty of copper grease.

... Anyway, I managed to get the front ones to fit but the rear holes in the crossmember were completely in the wrong place! So, I drilled the holes again, reprotected them and assembled using plenty of copper grease.

The drawing was completely wrong. It showed spring washers when they should be flaunt and plain nuts when they should be nyloc

Last edited: