K4n3

Member

- Posts

- 30

Hi guys,

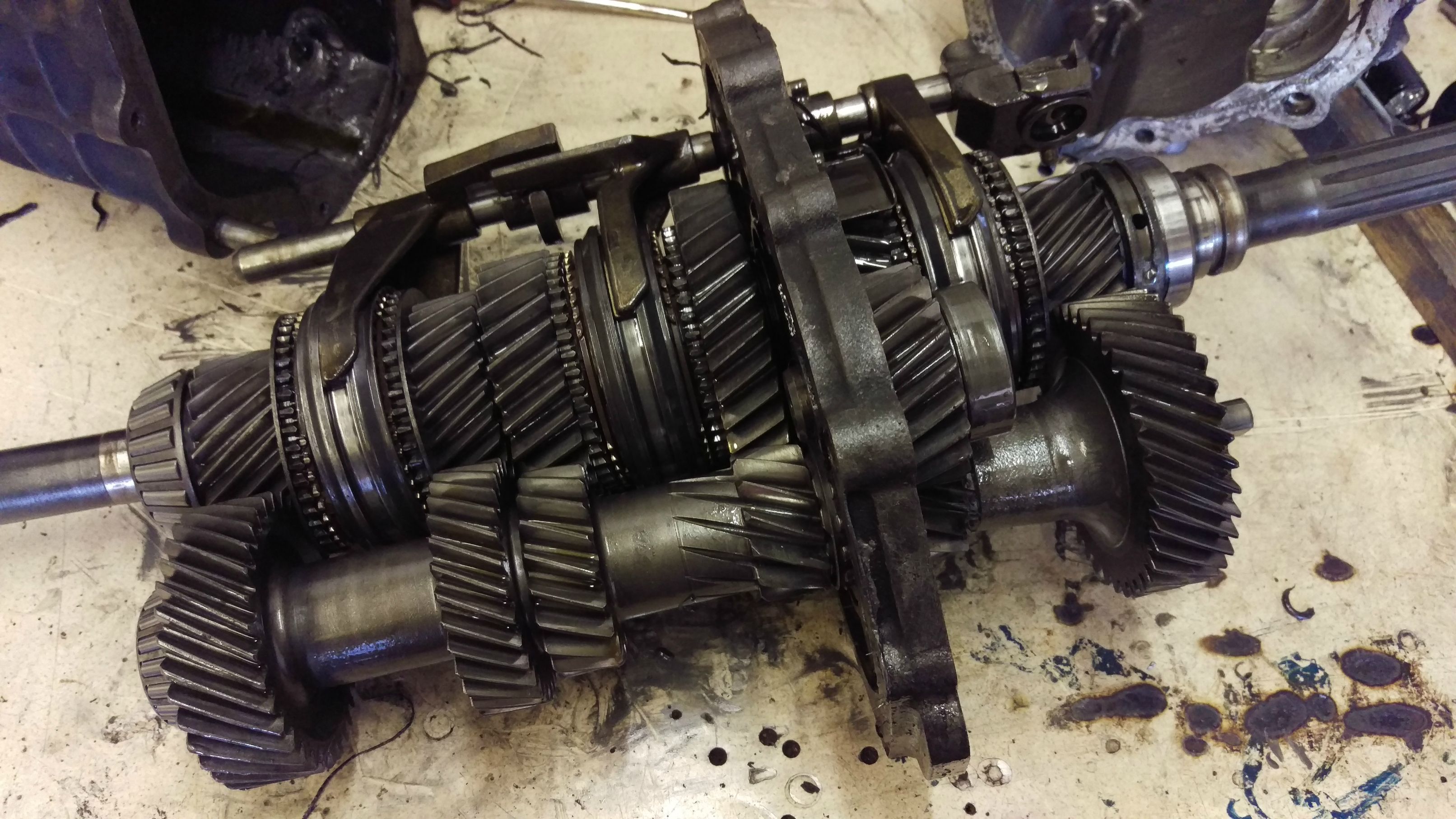

So I posted in another thread about noises from the gearbox, well I've finally got round to dismantling it.

I managed to get the main casing off, and found some nice little treats waiting in the bottom.

Am I right in thinking these form part of the synchromesh?

The problem started when I was having issues selecting second gear, but after a couple of months that seemed to disappear and it changed into a large 'notch' going into 4th gear.

Is this where the pieces should be? as from a quick glance, the other gears synchros seem to have something there.

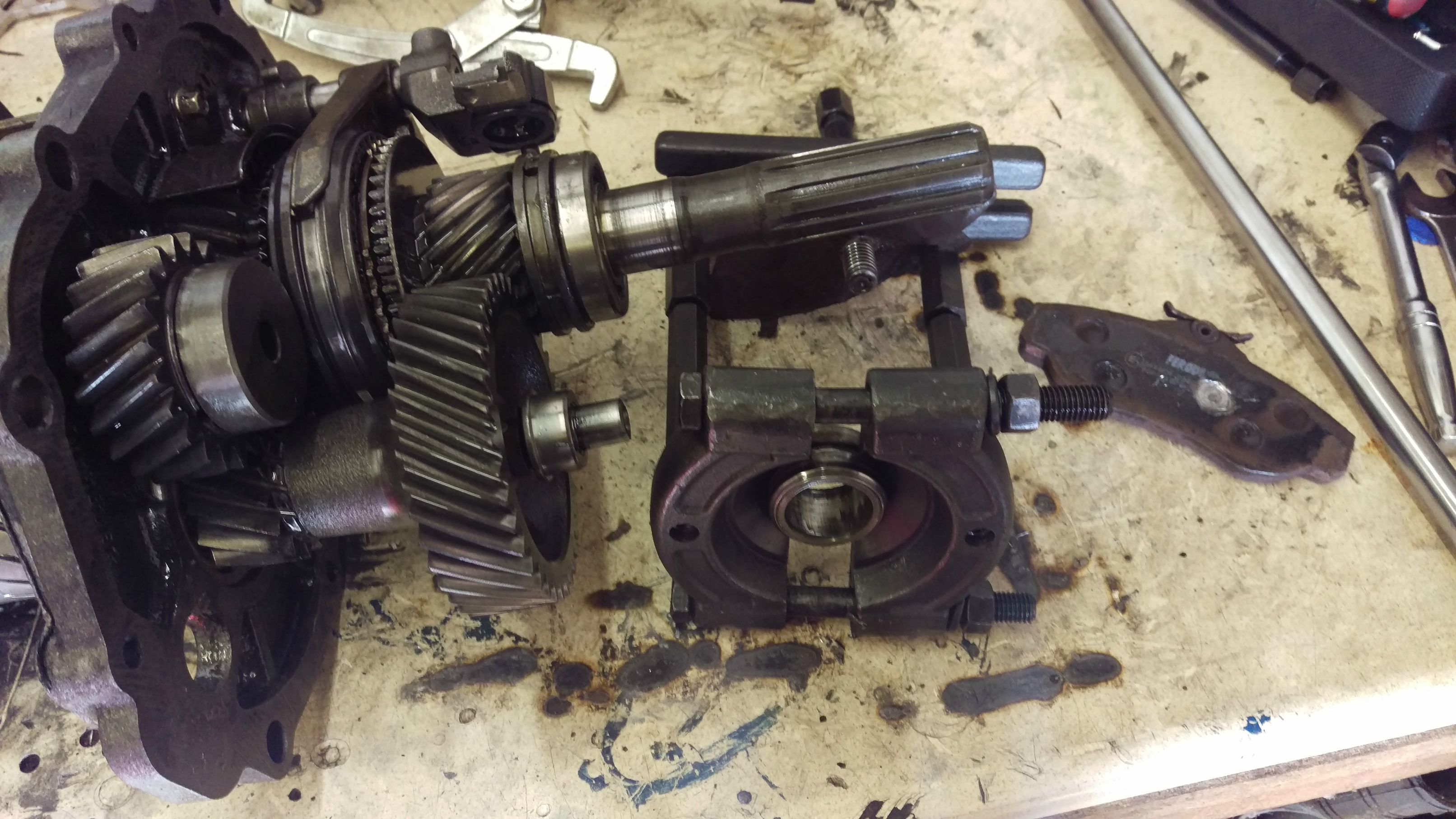

I'm also having problems trying to undo the set screw securing the yoke, it just will not budge.

Any tips? Do i have to remove the yoke to be able to remove the extension housing? Or should it just split away from the center plate regardless?

Cheers,

Kane

So I posted in another thread about noises from the gearbox, well I've finally got round to dismantling it.

I managed to get the main casing off, and found some nice little treats waiting in the bottom.

Am I right in thinking these form part of the synchromesh?

The problem started when I was having issues selecting second gear, but after a couple of months that seemed to disappear and it changed into a large 'notch' going into 4th gear.

Is this where the pieces should be? as from a quick glance, the other gears synchros seem to have something there.

I'm also having problems trying to undo the set screw securing the yoke, it just will not budge.

Any tips? Do i have to remove the yoke to be able to remove the extension housing? Or should it just split away from the center plate regardless?

Cheers,

Kane