Sorry, Im a bit pushed for time at the moment so Ill just provide a bit more information for now with a fuller reply to follow later.

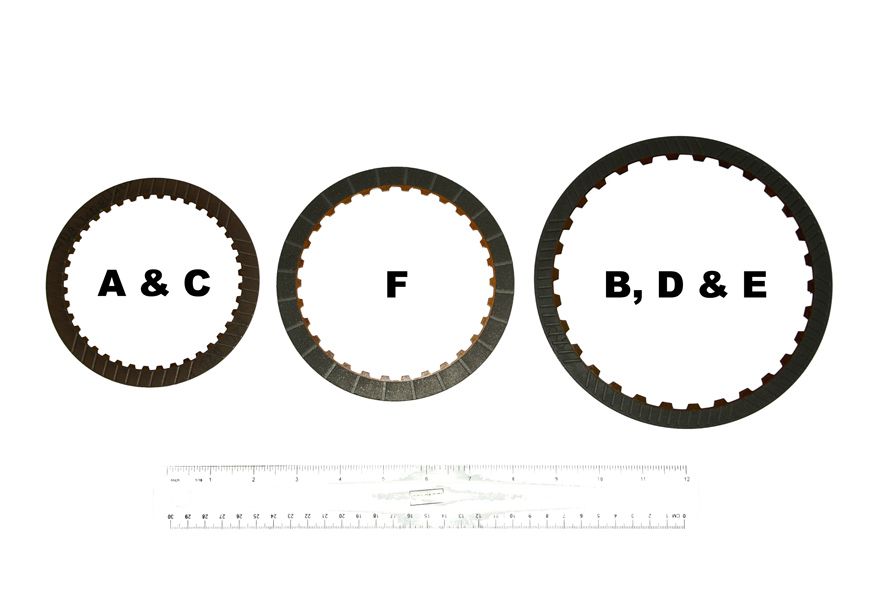

The A & C clutch friction & steel plates are identical (A = 6 plates, C = 4 plates)

The B, D & E clutch friction and steel plates are identical (B = 6 plates, D = 4 plates, E = 5 plates)

The F plates are unique to the F-Brake (6 plates)

Its common to have to drill out the F drum countersunk screws because they seize on the taper but its important to remove just the countersunk top (they go with a pop as the tension is released). If you drill down into the screw itself theres a chance that youll go all the way through and into the piston.

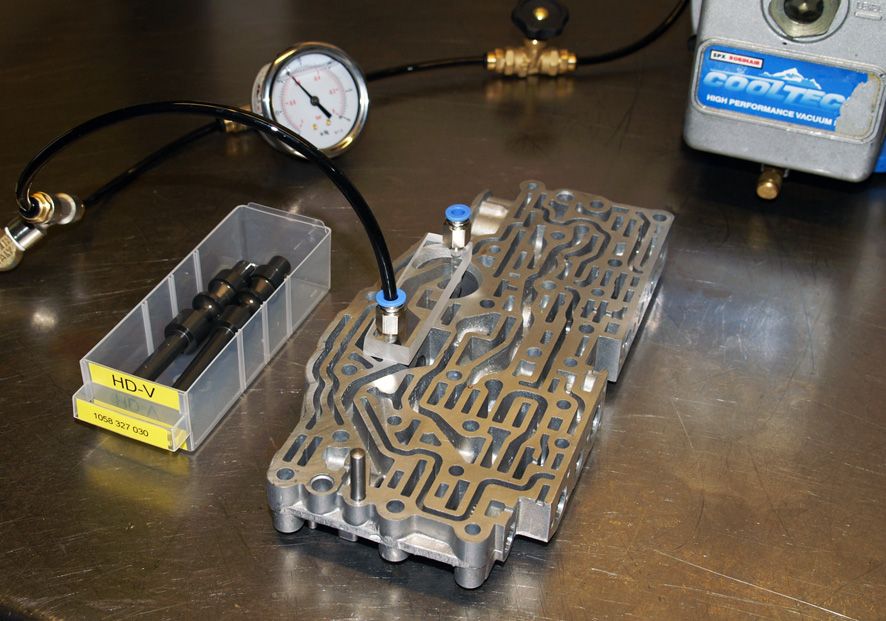

The calculations shown in the repair manual to determine the clutch pack clearance (which is adjusted using different thickness snap rings to retain the end plates) are complicated by the wavy plate (between the piston and the first steel plate) being compressible. The procedure is therefore to preload the clutch pack with 200N of force before the height measurements are made. I use a 20kg weight for this purpose.

However, the control system in the 5HP24 is so sensitive to clutch slip (by immediately dropping into failsafe mode if it senses any) its unusual for the clutch plates to wear. If the friction plates are dark brown in colour (rather than black) and theres no heat spots on the steel plates then theyre probably okay. As a rough guide the individual plate thicknesses should be :

A & C friction = 1.55mm

A & C steel = 2.07mm

B, D & E friction = 1.61mm

B, D & E steel = 2.95mm

F friction = 1.60mm

F steel = 1.78mm