Latest installment .. 300 Tdi engine into the 90 instead of the poorly 19J.

So the Disco drowned but we recovered it and kept it all, including the engine, but it's been stood for a year without being turned over, and making a slight mistake, means I drained it and didn't re-fill it with oil! So we've been stripping it down in TC's workshop .. Coffee, warm fire, dry .. cosy cosy ..

Incidentally the roofrack on TC's Defender 90, in the pic is for sale .. If anyone wants it make him an offer, drive to his place and we'll fit it, properly bolted to the roof gutters, not clamped, for the price!

So, the 300 engine lifted out of my trailer and hanging behind TC's other Defender, currently being cleaned up and fettled to sell it on ..

So we built an engine stand to allow us to hold steady but also to rotate the engine relatively easy and work on it ...

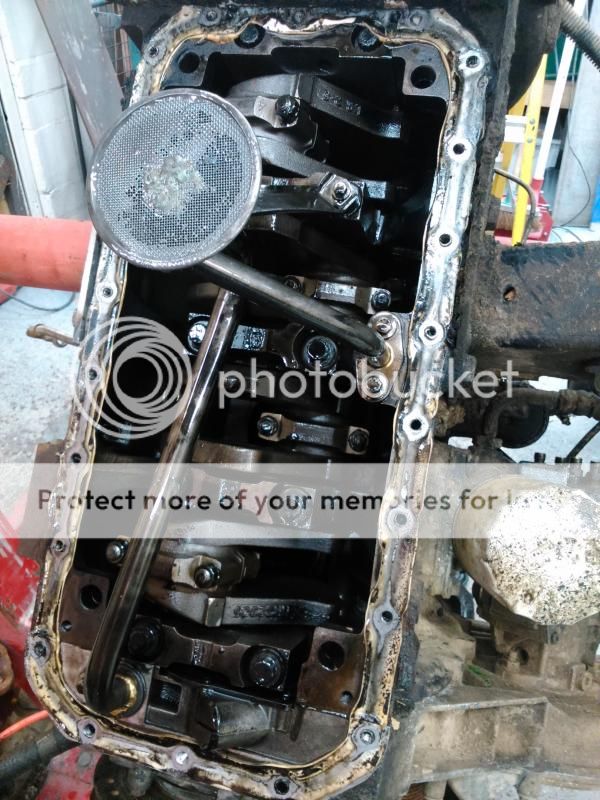

Bottom end looks OK, main bearings are clean, still have oil on them and undid and redid easily ..

The sump oil filter/pickup has a load of gasket goo on it so that'll be cleaned up, but that's the only issue down below really.

The head, however, has issues. Pistons are stuck, probably the valves are and there's mould growing .. but no rust!! The mould and 'crap' has just wiped off, see the tops of the pistons which were identical to the vales/combustion chamber .. and that's just with paper wipes so it's looking like it's a relatively minor clean-up needed after all! Head gaskets ace, no issues, but we'll use a new one anyway .. don't want to skimp!!

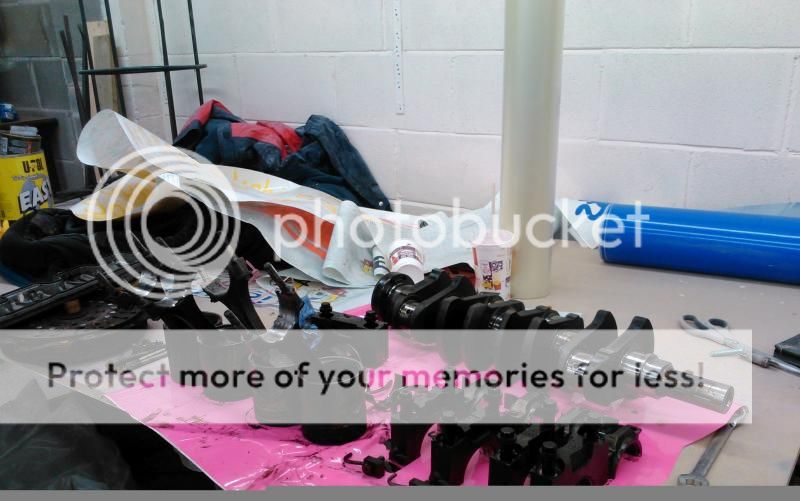

So it's looking like all it needs is the crank removing, pistons knocking out, bores honing and pistons cleaning, valves ditto and re-lapping then putting back together!

Plan today is take the timing gear off, crank out, and at least remove the pistons. Hopefully they'll clean up OK .. we'll see but I have very limited money available so hopefully most will be cleaned up rather than replaced, hopefully. Then strip the head so we can make sure the valves work OK and re-build it all.

The engines done 135,000 ish miles but looks sweet! (Other than above, obviously) See the head gasket, no issues at all, the actual piston bores are fine, no scratches or pitting or lips and same with piston and valve tops. So long as the injector pump is Ok there's no reason it won't run once it's turning over!

We'll run it on a simplified wiring loom, indeed it has no wiring loom now, we'll make one up to bastardise it between the 300 and 19j necessities .. might need a 200 fuel solenoid, but TC's an electrical wizard, so that's in his hands!!

Happy ..