Hello folks. My interior mirror had fallen off ages ago. Had a horrible suction one. Looked on here and saw the mgf interior mirror mod. Mines a 3 door. Does anyone know if the interior light wiring comes down the front offside pillar? I could take it off and look I suppose. But just asking first

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

MGF interior mirror mod

- Thread starter Rosewood

- Start date

This site contains affiliate links for which LandyZone may be compensated if you make a purchase.

Jayridium

Well-Known Member

- Posts

- 1,418

- Location

- Pedronapper (Peterhead)

Hiya, I did this mod about a year ago, have a look at the thread I wrote up about it:Hello folks. My interior mirror had fallen off ages ago. Had a horrible suction one. Looked on here and saw the mgf interior mirror mod. Mines a 3 door. Does anyone know if the interior light wiring comes down the front offside pillar? I could take it off and look I suppose. But just asking first

https://www.landyzone.co.uk/land-ro...tesy-light-and-mgf-mirror-into-3-door.358668/

That looks amazing. My mod will be less spectacular but I think the MGF mirror Is a nice compromise. I was hoping not to have to remove the headlining which is why I was hoping I could run the wires to the right hand pillar and so only have to remove that piece of trim

Had a brief look under the trim on the right hand pillar. The aerial appears to run down ther with two wires are wrapped around it. I think these might be the wires I need

The interior lights uses 3 wires, one earth which is black (that could be obtained locally to the light), one purple which is permanently live and one switched to groud by the CCU, unfortunately I can't remember the colour though.

Ill take the interior light down and trace the wires I think. Thanks for that. I think its purple with a white stripe

Purple/white sounds familiar. I can't remember if the CCU earth's that to put the light on when the door is open, or supplies battery voltage when the door is open, but the former would be conventional.

Jayridium

Well-Known Member

- Posts

- 1,418

- Location

- Pedronapper (Peterhead)

The wires do run down the pillar, purple + purple with white tracer. The thread I linked to shows which is which and explains the way they are wired as there is some smoke and mirrors involved with the body control unit PWM'ing one of the lines effectively giving you two live wires until the BCU drops one wires voltage level to create a potential difference. If you aren't keen on dropping the headlining, you could probably squeeze the wiring in from the front right by removing the driver's sun visor, partially removing the driver's door seal, and springing the front right side of the headlining from its trim clips in that corner. That should give you enough flex to get headlining down just enough to snake your three wires between the roof and the headlining.

You'll need to splice onto the purple and purple/white wires behind the A-Pillar trim, and you'll also need an earth. You will easily manage to put an earth in behind the A-Pillar trim by simply drilling a small hole into the A-Pillar and screwing a self tapper into that hole, and using that self tapper to secure / connect an earth wire with an eyelet terminal crimped on it. If you don't have any crimp on terminals you can make a ghetto eyelet by baring an inch and a bit of wire, splitting the strands in to two bundles, twisting them into two neat branches, then doing two twists of the two branches around each other, putting a suitably sized screw / pin / screwdriver etc between the branches, and then twisting the remaining length of wires together. The wires in the A-Pillar don't have a lot of give / slack in them, so it's not going to be possible to do a traditional cut, bare, twist, and solder splice on them. What you're going to have to do is remove a section of the insulation sheathing from the middle of the wire. I often do this with a cigarette lighter, simply burn about an inch of insulation, then scrape off the charred remnants by running the wire between my thumb nail and index fingertip, using the thumbnail as a scraper. Once you've burned & scraped enough insulation you will then wrap your new splice wire around the original metal cores, solder the joint and tape it up. That's a lot of words, I'll make a diagram.

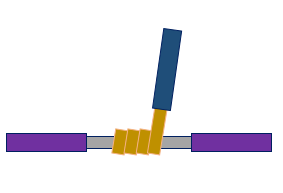

IIRC the wire strands in these wires are silvery aluminium looking rather than goldy coppery coloured, but even if they are copper, it's helpful for this diagram to have the original wires in silver, and you might benefit from "tinning" the original wires before soldering on the new splice which you'll wrap around the bare wire strands:

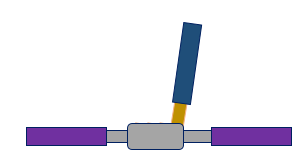

After wrapping it around, solder the joint:

I'm going to suggest wiring this up with 3 core 1.0mm or 1.5mm cable, it will give you a very OE look to the wiring poking down from the headlining to the mirror and be easier to manipulate when you poke the wire through the gap between the headlining and the roof.

So, with the above info on splicing the wiring, what to do to get enough give in the headlining without having to fully remove it, and a bit more information on the wiring colours etc in my thread I linked to earlier, I think you should be all set to wire in the MGF mirror. Best of luck and post some photos once its installed

You'll need to splice onto the purple and purple/white wires behind the A-Pillar trim, and you'll also need an earth. You will easily manage to put an earth in behind the A-Pillar trim by simply drilling a small hole into the A-Pillar and screwing a self tapper into that hole, and using that self tapper to secure / connect an earth wire with an eyelet terminal crimped on it. If you don't have any crimp on terminals you can make a ghetto eyelet by baring an inch and a bit of wire, splitting the strands in to two bundles, twisting them into two neat branches, then doing two twists of the two branches around each other, putting a suitably sized screw / pin / screwdriver etc between the branches, and then twisting the remaining length of wires together. The wires in the A-Pillar don't have a lot of give / slack in them, so it's not going to be possible to do a traditional cut, bare, twist, and solder splice on them. What you're going to have to do is remove a section of the insulation sheathing from the middle of the wire. I often do this with a cigarette lighter, simply burn about an inch of insulation, then scrape off the charred remnants by running the wire between my thumb nail and index fingertip, using the thumbnail as a scraper. Once you've burned & scraped enough insulation you will then wrap your new splice wire around the original metal cores, solder the joint and tape it up. That's a lot of words, I'll make a diagram.

IIRC the wire strands in these wires are silvery aluminium looking rather than goldy coppery coloured, but even if they are copper, it's helpful for this diagram to have the original wires in silver, and you might benefit from "tinning" the original wires before soldering on the new splice which you'll wrap around the bare wire strands:

After wrapping it around, solder the joint:

I'm going to suggest wiring this up with 3 core 1.0mm or 1.5mm cable, it will give you a very OE look to the wiring poking down from the headlining to the mirror and be easier to manipulate when you poke the wire through the gap between the headlining and the roof.

So, with the above info on splicing the wiring, what to do to get enough give in the headlining without having to fully remove it, and a bit more information on the wiring colours etc in my thread I linked to earlier, I think you should be all set to wire in the MGF mirror. Best of luck and post some photos once its installed

Jayridium

Well-Known Member

- Posts

- 1,418

- Location

- Pedronapper (Peterhead)

Excellent - well done mate!

Similar threads

- Replies

- 2

- Views

- 602

- Replies

- 1

- Views

- 592

- Replies

- 35

- Views

- 3K

- Replies

- 9

- Views

- 5K