QRHcooper

Member

- Posts

- 42

- Location

- Thringstone

Hi guys!

Sorry for being AWOL recently, work ect...

Anyway, I have carried a few minor maintenance tasks on the Disco since my last update and compiled them below for your pleasure

I also have a recurring issue which I have found to be caused by the connection (or lack there of) from the loom connection point on the front/right of the engine.

Ok, onto jobs I have succeeded with thus far,

I also have a sports exhaust winging itself through the post which should hopefully be fitted by the weekend to improve on the uninspiring exhaust note currently emitting from the standard pipe and while I'm under there I think Ill fit the side steps currently hiding in the shed since I attempted and failed to removed the heavily oxidised existing mud-flaps on the disco I will be liberal with the penetrating fluid a few days before in preparation

I will be liberal with the penetrating fluid a few days before in preparation

Downloaded the app on my phone and connect via blue tooth

Wanted the SST version originally but, got a set of these for a good price

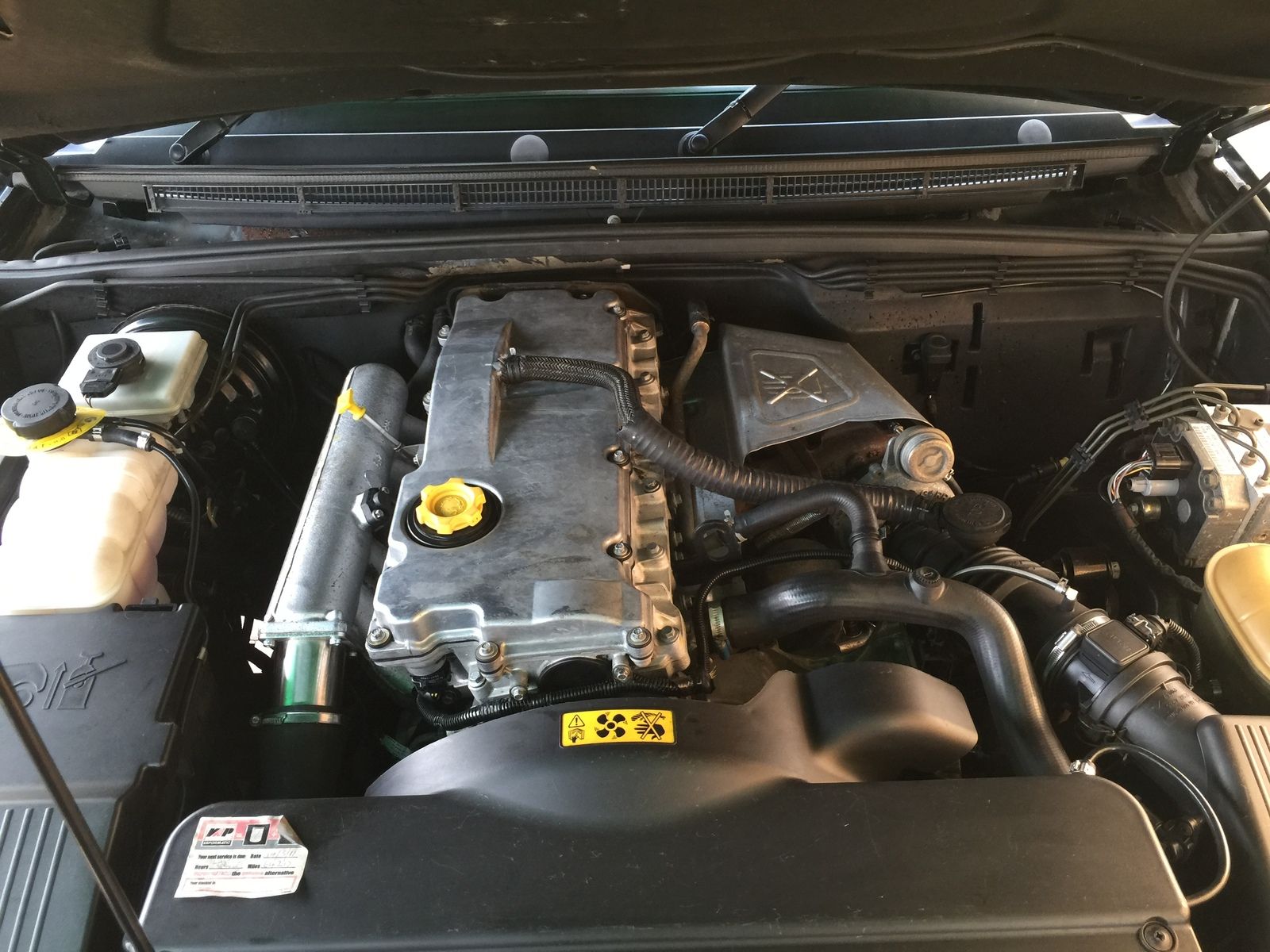

Nice clean engine bay after a thorough degrease! it was minging

Rocker cover seal was starting to disintegrate, replaced with a shiny new one

All seems to be in order in there, no spanners or squirrels to be seen

Took photos of the injector numbers/letters in order as I read that this could be useful if required for another job?

New harness going in.

Will post updated pictures of her in her new shoes and legs spread once all fitted

Cheers guys and thanks for looking

Sorry for being AWOL recently, work ect...

Anyway, I have carried a few minor maintenance tasks on the Disco since my last update and compiled them below for your pleasure

I also have a recurring issue which I have found to be caused by the connection (or lack there of) from the loom connection point on the front/right of the engine.

- Fault happens during normal driving

- Coolant Light comes on, shoots up to max temp, M+S, Engine Light. Engine stalls...

- Engine will turn over but not fire

- After much banging, pulling and prodding I found that if I "wiggle" the connection from the loom to the injector harness the coolant light extinguishes and the engine starts!

- Have cleaned out all connections including the ECU (very slight amount of oil there, nothing serious) with contact cleaner.

- Appears to me that the connector is "unwiggling" itself during normal use as there was a cable tie present from the previous owner..

Ok, onto jobs I have succeeded with thus far,

- Replaced the crank shaft circular seal (literally fell straight out..) Had been leaking oil slowly which the main fan had delighted in throwing all over the engine..

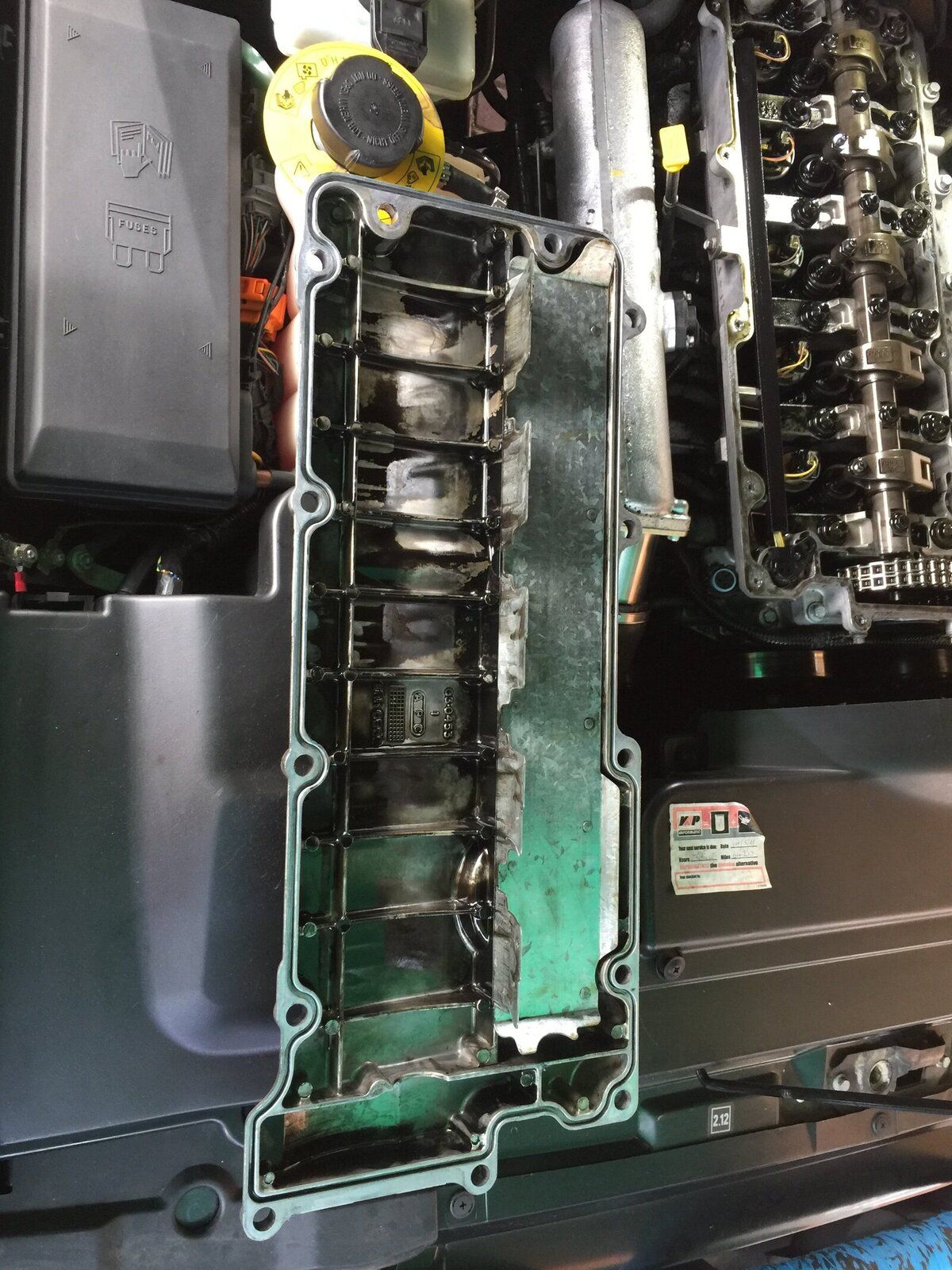

- Replaced the rocker seal. Had been slightly weeping from a number of points contributing to the oil thrown by the fan..

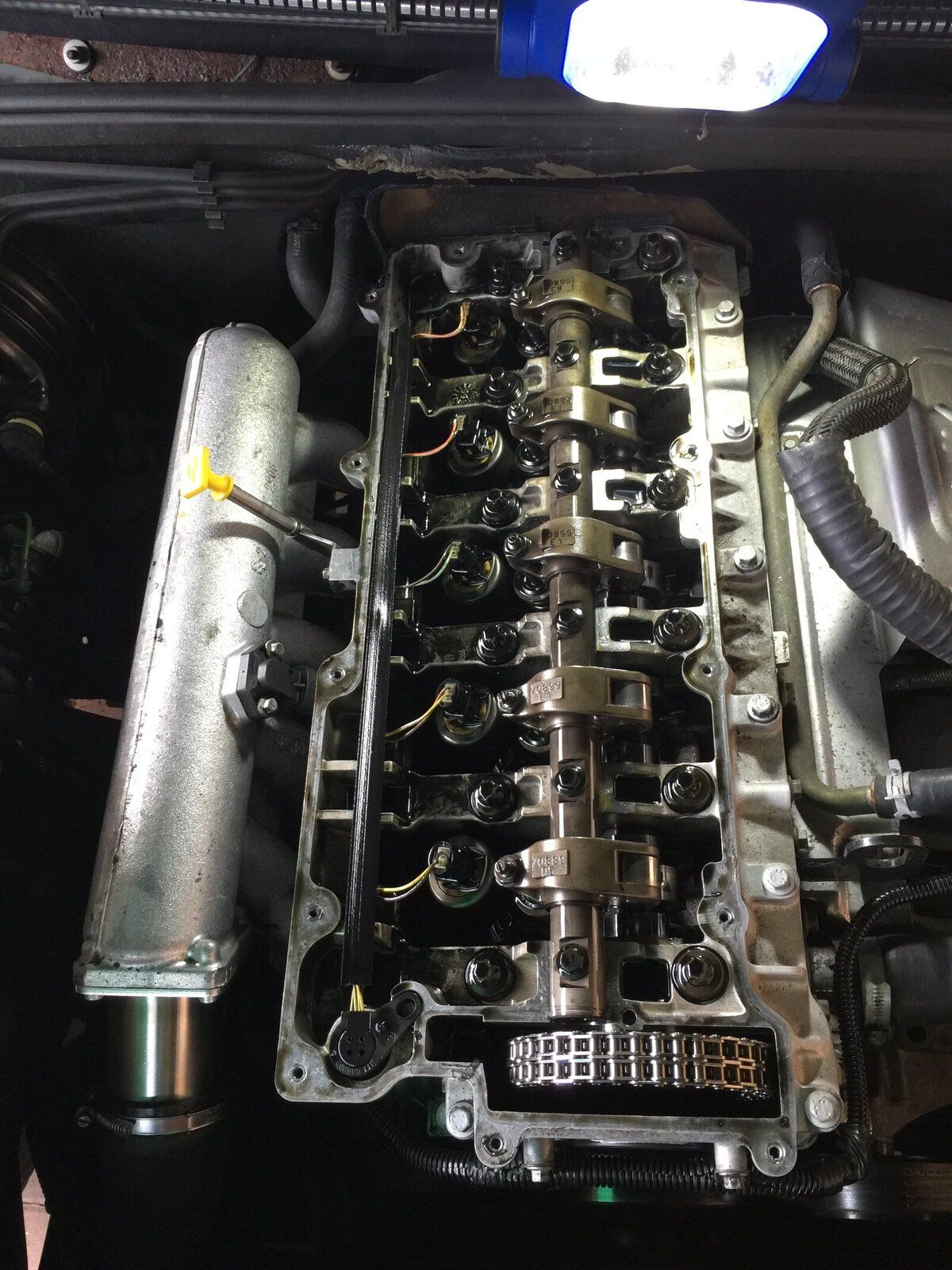

- While I was under the rocker cover I also replaced the injector loom as it seemed logical to do so whilst it was apart.

- Applied a good few sqirts of grease to the drive shaft grease nipples! Been having nightmares about them exploding ever since reading about them failing on here

- All new drilled/grooved discs and pads. R/R/H/S caliper had seized on one side but, a liberal application of penetrating fluid sorted it right out!

- Had the ECU flashed by Dynachip which coupled with the EGR blanking has transformed her from the sluggish beast she was to a not so sluggish beast

- Used my new Lynx Evo diagnostic tool for the first time! Checked all faults readings and found nothing scary (already done recently for the remap) Brilliant piece of kit and I love all the different functions you have available!

I also have a sports exhaust winging itself through the post which should hopefully be fitted by the weekend to improve on the uninspiring exhaust note currently emitting from the standard pipe and while I'm under there I think Ill fit the side steps currently hiding in the shed since I attempted and failed to removed the heavily oxidised existing mud-flaps on the disco

Downloaded the app on my phone and connect via blue tooth

Wanted the SST version originally but, got a set of these for a good price

Nice clean engine bay after a thorough degrease! it was minging

Rocker cover seal was starting to disintegrate, replaced with a shiny new one

All seems to be in order in there, no spanners or squirrels to be seen

Took photos of the injector numbers/letters in order as I read that this could be useful if required for another job?

New harness going in.

Will post updated pictures of her in her new shoes and legs spread once all fitted

Cheers guys and thanks for looking

Last edited: