My freelander is a 2002 v6 with 46000 miles under its belt. It is thumping up and down a couple of gears. Can anyone give me any info on gearbox fault code 0715 (Input /Turbine speed sensor circuit). I know the sensor is in the gearbox. Can the gearbox be removed without the engine being removed? Any other ideas about bad connections that might cause this fault code. Just some general advice would be good.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

jatco gearbox fault.

- Thread starter Mower1

- Start date

This site contains affiliate links for which LandyZone may be compensated if you make a purchase.

Nodge68

Well-Known Member

- Posts

- 32,504

- Location

- Near Newquay

It's worth checking the barrel connectors. Iirc the speed sensors have a resistance of 400-600 ohms. The box can be removed leaving the engine in place, a lot of dismantling is required to remove the box. It's a heavy lump too, apparently around 90 Kgs in weight. I think the input speed sensor is visible if the end cover is removed but can't quite remember. If it can be changed like that then the box might not need to be removed.

Hippo

Lord Hippo

- Posts

- 51,923

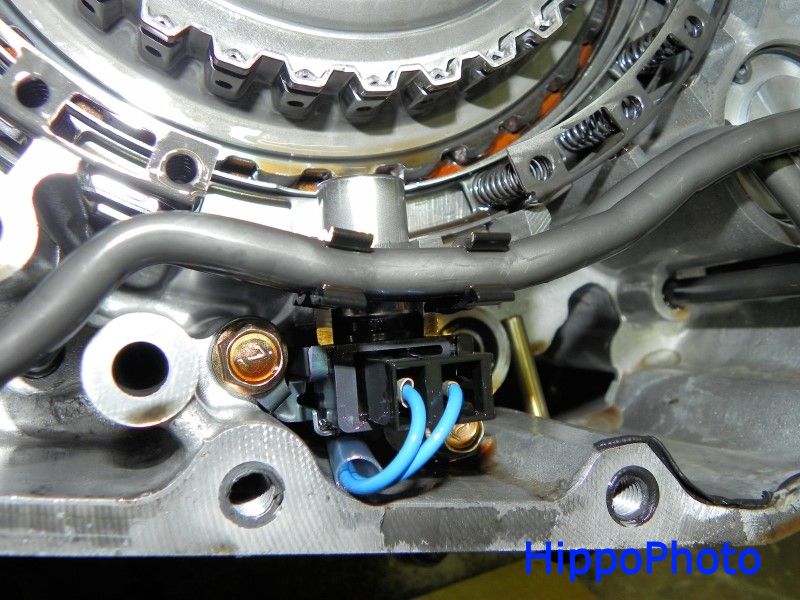

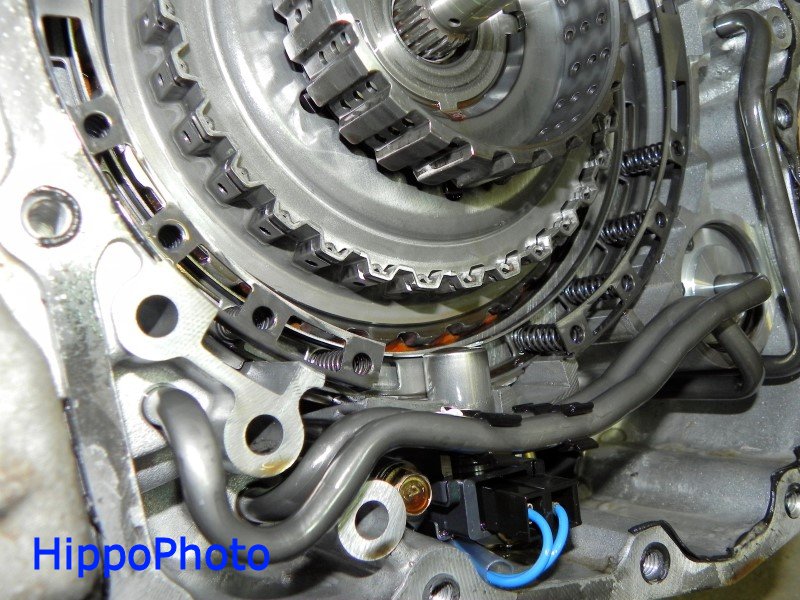

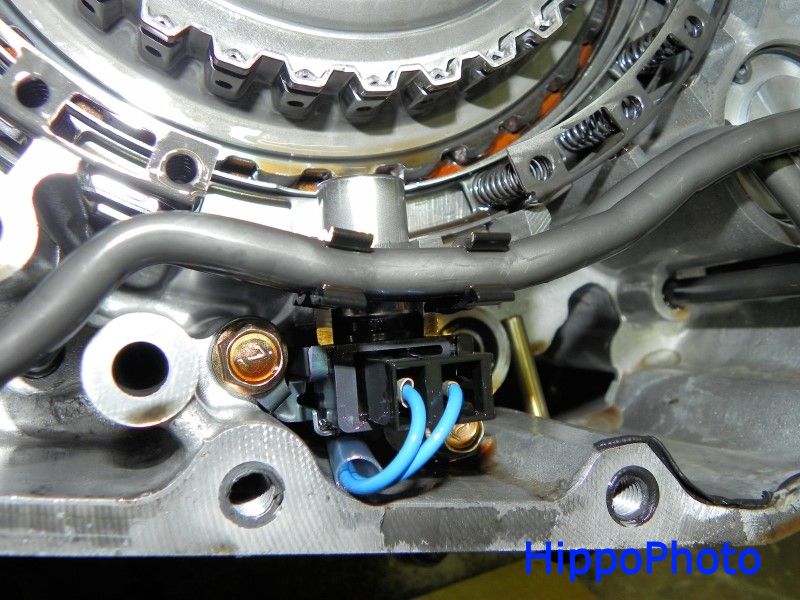

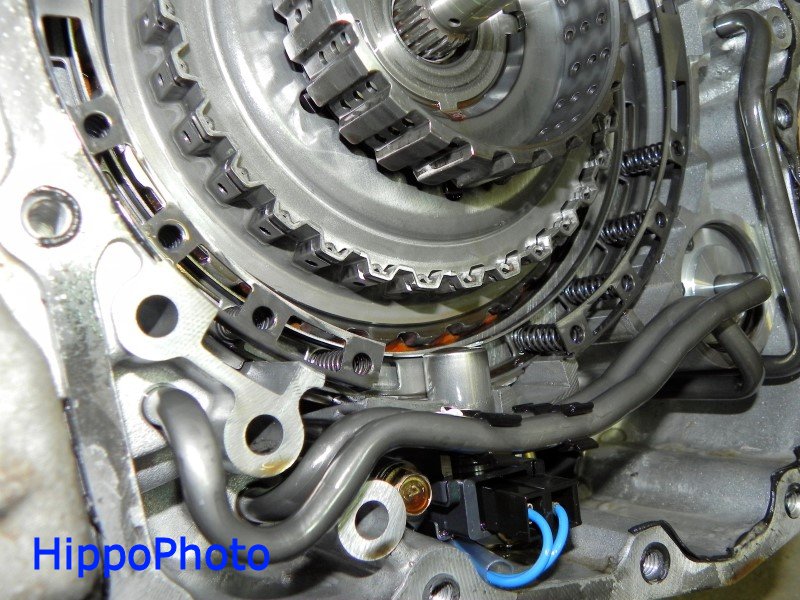

The turbine speed sensor is the easier sensor to get to. It sits just inside the side plate.

According to rave P0715 is for the turbine speed sensor = no signal. So this would make me think the sensor is broken, or the wiring to it is broken. As said above check the barrel connectors are joined ok. Also check for breaks in the wires/harness and measure the resistance of the sensor via the barrel connectors. Some attachments and help on this fred: http://www.landyzone.co.uk/lz/f9/jatco-auto-box-true-231171-2.html

I would also stop driving it if it were mine as thumping into gear will only cause damage to your auto.

Additional words for the web searchers: Jatco jf506e land rover landrover freelander

DSCN3005 qCW8CI3

DSCN3009 Ktlfqpv

According to rave P0715 is for the turbine speed sensor = no signal. So this would make me think the sensor is broken, or the wiring to it is broken. As said above check the barrel connectors are joined ok. Also check for breaks in the wires/harness and measure the resistance of the sensor via the barrel connectors. Some attachments and help on this fred: http://www.landyzone.co.uk/lz/f9/jatco-auto-box-true-231171-2.html

I would also stop driving it if it were mine as thumping into gear will only cause damage to your auto.

Additional words for the web searchers: Jatco jf506e land rover landrover freelander

DSCN3005 qCW8CI3

DSCN3009 Ktlfqpv

Last edited:

Some attachments and help on this fred: http://www.landyzone.co.uk/lz/f9/jatco-auto-box-true-231171-2.html

That fred looks familiar

Hippo

Lord Hippo

- Posts

- 51,923

Lucky find on goo gle.That fred looks familiar

Cheers, got more information than soft Mick now, thanks to all three of you. Given me a new reason to live. It only thumps in to gear every now and again so hopefully not done too much damage. Going down the workshop now to fix the problem in under 5 mins. Well maybe not. Will let you know how I get on.

Hi all, here again. After much discussion with the previous owner of my freelander. He owned it from new in 2002, and is as much wiser man than me, I now have in my hand two solenoids from my gearbox. 2-4 duty solenoid and 2-4 timing solenoid. Although both gave good readings when checked (18 ohms for the timing sol and 3 ohms for the duty sol ) and it only took 45 mins to remove them we have decided to renew them wondering if one or both could be sticking.

We understand that it could still be an intermittent fault on the speed sensor but dare not use the car to test this theory in case of further damage. Any comments on our decision would be gratefully received. We were quoted £240 for a full set of solenoids and it is very tempting to renew all, but what if it is the speed/turbine sensor, Oh what a quandry. Any advice welcome.

Where is the best place to get these parts? Would landrover charge an arm and a leg?

Got to admit, it was a pleasant surprise to find things easy to get to and remove. Feel as though I might be able to get rid of the hosepipe I bought to attach to the exhaust when I replaced the thermostat housing. Looking forward to reading your replies.

Ray

We understand that it could still be an intermittent fault on the speed sensor but dare not use the car to test this theory in case of further damage. Any comments on our decision would be gratefully received. We were quoted £240 for a full set of solenoids and it is very tempting to renew all, but what if it is the speed/turbine sensor, Oh what a quandry. Any advice welcome.

Where is the best place to get these parts? Would landrover charge an arm and a leg?

Got to admit, it was a pleasant surprise to find things easy to get to and remove. Feel as though I might be able to get rid of the hosepipe I bought to attach to the exhaust when I replaced the thermostat housing. Looking forward to reading your replies.

Ray

Hippo

Lord Hippo

- Posts

- 51,923

When I said earlier I would stop driving it if it were mine, I was thinking of normal daily driving. Driving it to test it is a risk, but one you have to take I guess. It won't necessarily cause damage, but it may do. Over time this could make things worse. I guess this is something we can only summarise. You need to start somewhere. What was the thinking behind removing the solenoids if your turbine speed sensor is reported to read incorrectly as per the computers P code? Did you remove the code, drive it, and the code didn't come back?Hi all, here again. After much discussion with the previous owner of my freelander. He owned it from new in 2002, and is as much wiser man than me, I now have in my hand two solenoids from my gearbox. 2-4 duty solenoid and 2-4 timing solenoid. Although both gave good readings when checked (18 ohms for the timing sol and 3 ohms for the duty sol ) and it only took 45 mins to remove them we have decided to renew them wondering if one or both could be sticking.

We understand that it could still be an intermittent fault on the speed sensor but dare not use the car to test this theory in case of further damage. Any comments on our decision would be gratefully received. We were quoted £240 for a full set of solenoids and it is very tempting to renew all, but what if it is the speed/turbine sensor, Oh what a quandry. Any advice welcome.

Where is the best place to get these parts? Would landrover charge an arm and a leg?

Got to admit, it was a pleasant surprise to find things easy to get to and remove. Feel as though I might be able to get rid of the hosepipe I bought to attach to the exhaust when I replaced the thermostat housing. Looking forward to reading your replies.

Ray

Part codes below:

The reason for not wanting to use the car till we had done some investigation was I thought I was very lucky not to have damaged the gearbox beyond repair when it locked up. Like you I enjoy my car and dont want to hurt it.

Nearly forgot, the oil was ok, no bits stuck to the plug.

Ray

Hippo

Lord Hippo

- Posts

- 51,923

When my auto was leaking the oil level dropped and it's gear change was as if someone drove into the back at a few mph while you were stationary. Too much of that and something's going to give. For me it meant a recon auto was fitted after the torque convertor feked up due to low oil. Leak got worse too and in more places.

Can the previous owner advise on the history of the car and the fault? Did this happen before you bought it?

Sensors giving incorrect readings will make the auto do strange things. Implausible speeds v gearing etc I guess. The auto is probably the most complex part of a car. Electronics, hydraulics and mechanical all working together. I'm no eggspert on auto's but as said above suffered with them. If the turbine sensor is considered faulty then that would need looked at.

Does the fault occur when the auto is cold or hot etc?

Can the previous owner advise on the history of the car and the fault? Did this happen before you bought it?

Sensors giving incorrect readings will make the auto do strange things. Implausible speeds v gearing etc I guess. The auto is probably the most complex part of a car. Electronics, hydraulics and mechanical all working together. I'm no eggspert on auto's but as said above suffered with them. If the turbine sensor is considered faulty then that would need looked at.

Does the fault occur when the auto is cold or hot etc?

Yes something similar did happen a year or so before I got the car but that was when changing up. It was ok for about a year then it happened again but on a down shift. It was then ok for a few months and started again on the down shift but more regularly.It occurs when its hot or cold.

We have been at it again this evening and managed to get a zero reading on the speed sensor. Our plan is now to change speed sensor and put that right try again. Is it a simple job of removing the end plate while the engine is in situ or do we have to drop the engine and gearbox slightly. I read on one of the forums that most of the grearbox can be removed from the end but the engine has to be dropped slightly.As we are only removing the end plate I was kind of hoping it would be easy. Gunna start tomorrow evening, will let you know how we get on.

Ray

We have been at it again this evening and managed to get a zero reading on the speed sensor. Our plan is now to change speed sensor and put that right try again. Is it a simple job of removing the end plate while the engine is in situ or do we have to drop the engine and gearbox slightly. I read on one of the forums that most of the grearbox can be removed from the end but the engine has to be dropped slightly.As we are only removing the end plate I was kind of hoping it would be easy. Gunna start tomorrow evening, will let you know how we get on.

Ray

Nodge68

Well-Known Member

- Posts

- 32,504

- Location

- Near Newquay

The box end plate is easy to remove. You will need to unbolt the box mount and lower the box below the inner wing level.

Last edited:

Hippo

Lord Hippo

- Posts

- 51,923

The bolts are 17mm but it's a bit loose. 16mm is not big enough. I had problems with these bolts. The ideal socket has had the slopped end bit cut off so you get more socket grip on the nut.

From what I remember the whole end plate is spring loaded. See pic below. you can take it oft, just pull it away horizontal. Probably not enough room unless you lower the gearbox a lot. The best way to put it back is to push it on and straight and put the bolts in and start turning them. Evenly turn the bolts to push the plate against the gearbox. The spring will compress I think. The plate is a funny shape inside. If you take anything out from inside, make sure it goes back properly. Ere's a video of inside the plate.

Freelander 2001 v6 Jatco JF506E Automatic Gearbox - YouTube

From what I remember the whole end plate is spring loaded. See pic below. you can take it oft, just pull it away horizontal. Probably not enough room unless you lower the gearbox a lot. The best way to put it back is to push it on and straight and put the bolts in and start turning them. Evenly turn the bolts to push the plate against the gearbox. The spring will compress I think. The plate is a funny shape inside. If you take anything out from inside, make sure it goes back properly. Ere's a video of inside the plate.

Freelander 2001 v6 Jatco JF506E Automatic Gearbox - YouTube

Last edited:

Cheers hippo, don't think anything fell out but an arm full of oil. It looked like your way of sticking it back on was the only way but just thought I would make sure. On me olidays abroad in west Wales now till a week on Monday, won't be doing anything else till then. By the way, took the solenoids off and found 2 sticking and one maybe sticking. Will be able to compare when new solenoids arrive. Don't suppose the hawkeye can blow through the sols like we can. If they are electrically sound then the hawkeye will give them a clean bill of health. The car is now 11 years old, every thing original but the thermostat housing and water pump. I suppose we have to expect some wear and tear. Thanks for your help will come back next week with an update.

Ray.

Ray.

Hippo

Lord Hippo

- Posts

- 51,923

Hawkeye can't do anything like that.Cheers hippo, don't think anything fell out but an arm full of oil. It looked like your way of sticking it back on was the only way but just thought I would make sure. On me olidays abroad in west Wales now till a week on Monday, won't be doing anything else till then. By the way, took the solenoids off and found 2 sticking and one maybe sticking. Will be able to compare when new solenoids arrive. Don't suppose the hawkeye can blow through the sols like we can. If they are electrically sound then the hawkeye will give them a clean bill of health. The car is now 11 years old, every thing original but the thermostat housing and water pump. I suppose we have to expect some wear and tear. Thanks for your help will come back next week with an update.

Ray.

How do you know the solenoids were sticking? Once removed can you push them in/out to feel for smoothness of operation?

Similar threads

- Replies

- 24

- Views

- 874