Hi really need some advice ..... recon vcu failed and put some strain on pinion..... pinion got a bit hot and rear oil seal failed (VCU now fixed) - this is not the 'o' ring but appears to be the seal that is located behind the flange of the propshaft mounting. IRD seems fine just the seal is poor and it aint going to get any better!

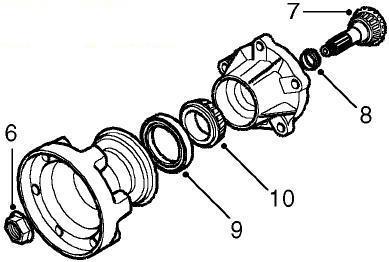

Question:- when the prop is disconnected - you see a big single nut holding the prop flange mount on - located at it's centre. Is it safe to attempt to unscrew this???? I think it may be possible to unscrew the nut and slide the prop flange off.....exposing the rear oil seal .... which hopefully can be 'poped out' ......... Has anybody done this, what worries me is the big nut holding the flange on could be set at a preload with a collapsable spacer .... as in most diffs.......... My diff is leaking quite badly ... hope there is a straightforward solution.

Question:- when the prop is disconnected - you see a big single nut holding the prop flange mount on - located at it's centre. Is it safe to attempt to unscrew this???? I think it may be possible to unscrew the nut and slide the prop flange off.....exposing the rear oil seal .... which hopefully can be 'poped out' ......... Has anybody done this, what worries me is the big nut holding the flange on could be set at a preload with a collapsable spacer .... as in most diffs.......... My diff is leaking quite badly ... hope there is a straightforward solution.