UnitLandy

Well-Known Member

- Posts

- 155

- Location

- Whittonstall

Hi folks,

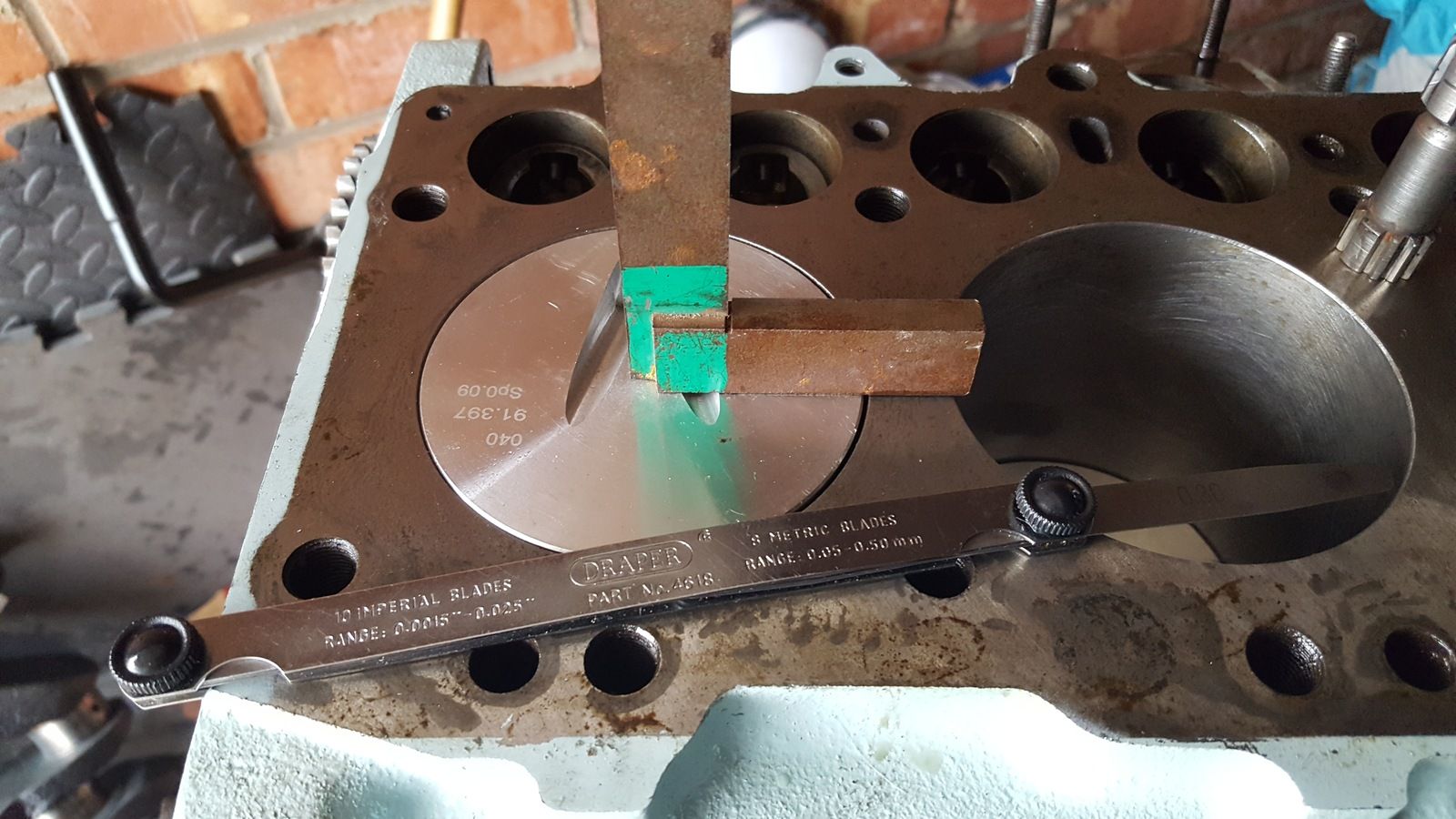

Hope this is in the appropriate place, but I hoped to ask your advice on my 2.25 diesel engine. No.1 piston head peeks over the surface of the engine block surface by 0.30mm on the rear edge of the piston but not the front edge. The gasket is thicker than this and there's no movement of the head block when the gasket is in place but I'm not sure how much the copper gasket will compress after the head blocks torqued up.

The pistons are Bearmach +40 and the engine has had a rebore of +40 (obviously haha) and I'm hoping the machine shop hasn't made any f**k ups when re-boring the engine. However, all other pistons do not pass the surface.

Could this be a dodgy piston/cylinder bore/piston ring?

Hope this is in the appropriate place, but I hoped to ask your advice on my 2.25 diesel engine. No.1 piston head peeks over the surface of the engine block surface by 0.30mm on the rear edge of the piston but not the front edge. The gasket is thicker than this and there's no movement of the head block when the gasket is in place but I'm not sure how much the copper gasket will compress after the head blocks torqued up.

The pistons are Bearmach +40 and the engine has had a rebore of +40 (obviously haha) and I'm hoping the machine shop hasn't made any f**k ups when re-boring the engine. However, all other pistons do not pass the surface.

Could this be a dodgy piston/cylinder bore/piston ring?