You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

how to change turbo on a TD4

- Thread starter gb8man

- Start date

This site contains affiliate links for which LandyZone may be compensated if you make a purchase.

Hi all help required i brought a 2004 freelander diesel 2 litre that would only start with easy start. Well thinking it may be air in the system as the lady i brought it from had a new fuel pump fitted then when she got home it failed to start. Anyway i brought it after starting it with easy start and drove it home 12 miles know problem at all the next day i decided to start on it and started it no problem it thought it had air in the system and cleared itself so having the bonnet up i noticed bubbles rising in the expansion tank. so i drove it 300 meters to my local garage he thought it could be head gasket going no smoke from the back and no over heating. i said should i put an additive in the coolant that may seal any leek so i did he said now take it for a run for at 20 miles to let it circulate. This i did running good no over heating well 3 miles from home suddenly a loud woosh noise followed by a ton of white smoke coming from the exhaust loss of power but no over heating manage to limp home engine covered in oil so what happened i know the turbo is now blown but dont know about if it was due to the headgasket help

That's a classic symptom of the high pressure fuel regulator O rings being split or not sealing correctly .that would only start with easy start

The low pressure fuel rail is self bleeding, so shouldn't be an issue, unless the pressure is too low .thinking it may be air in the system as the lady i brought it from had a new fuel pump fitted then when she got home it failed to start.

Are you sure it wasn't just the coolant returning from the bleed pipe, making it look like bubbles are rising?so having the bonnet up i noticed bubbles rising in the expansion tank.

Very unlikely to be the head gasket on a TD4.so i drove it 300 meters to my local garage he thought it could be head gasket going no smoke from the back and no over heating.

Never put those cooling system blockers in an engine, unless it's just too get a vehicle to the scrap yard. They're death to an engine.i said should i put an additive in the coolant that may seal any leek so i did he said now take it for a run for at 20 miles to let it circulate.

This i did running good no over heating well 3 miles from home suddenly a loud woosh noise followed by a ton of white smoke coming from the exhaust loss of power but no over heating manage to limp home engine covered in oil so what happened i know the turbo is now blown but dont know about if it was due to the headgasket help

It's unlikely to be the head gasket. How do you know the turbo has gone? The oil could just be from the dip stick, caused be a blocked crankcase filter.

I'd take to a garage that knows what the **** they're doing. No mechanic worth his salt will suggest using cooling system sealant.

Farmer hill

Member

- Posts

- 16

- Location

- Exmoor

That's a classic symptom of the high pressure fuel regulator O rings being split or not sealing correctly .

The low pressure fuel rail is self bleeding, so shouldn't be an issue, unless the pressure is too low .

Are you sure it wasn't just the coolant returning from the bleed pipe, making it look like bubbles are rising?

Very unlikely to be the head gasket on a TD4.

Never put those cooling system blockers in an engine, unless it's just too get a vehicle to the scrap yard. They're death to an engine.

It's unlikely to be the head gasket. How do you know the turbo has gone? The oil could just be from the dip stick, caused be a blocked crankcase filter.

I'd take to a garage that knows what the **** they're doing. No mechanic worth his salt will suggest using cooling system sealant.

Farmer hill

Member

- Posts

- 16

- Location

- Exmoor

Hello, I've followed ever step and managed to remove the turbo, but ...how on earth do you put a fresh 1 back on?? Been underneath it fir ages and I can't get to fix the pipe off the back of the engine to turbo back on? Any ideas, if not it's going to a proper mechanic

I can't get to fix the pipe off the back of the engine to turbo back on?

Any particular pipe?

Farmer hill

Member

- Posts

- 16

- Location

- Exmoor

It's a little oil pipe, I imagine goes into the sump? It goes back to the engine block, I can't get in to slide it over the steel joining peice

There are 2 oil pipes to the turbo. One is small and short that has a banjo bolt to secure it to the engine block, this feeds the oil to the bearings. The other is a larger rubber pipe, which takes the oil back to the sump. Which one can't you do?

Farmer hill

Member

- Posts

- 16

- Location

- Exmoor

Must be the retern pipe, can't fisicly get it back on

Hi everyone, managed to replace mine over weekend. Which was fine...

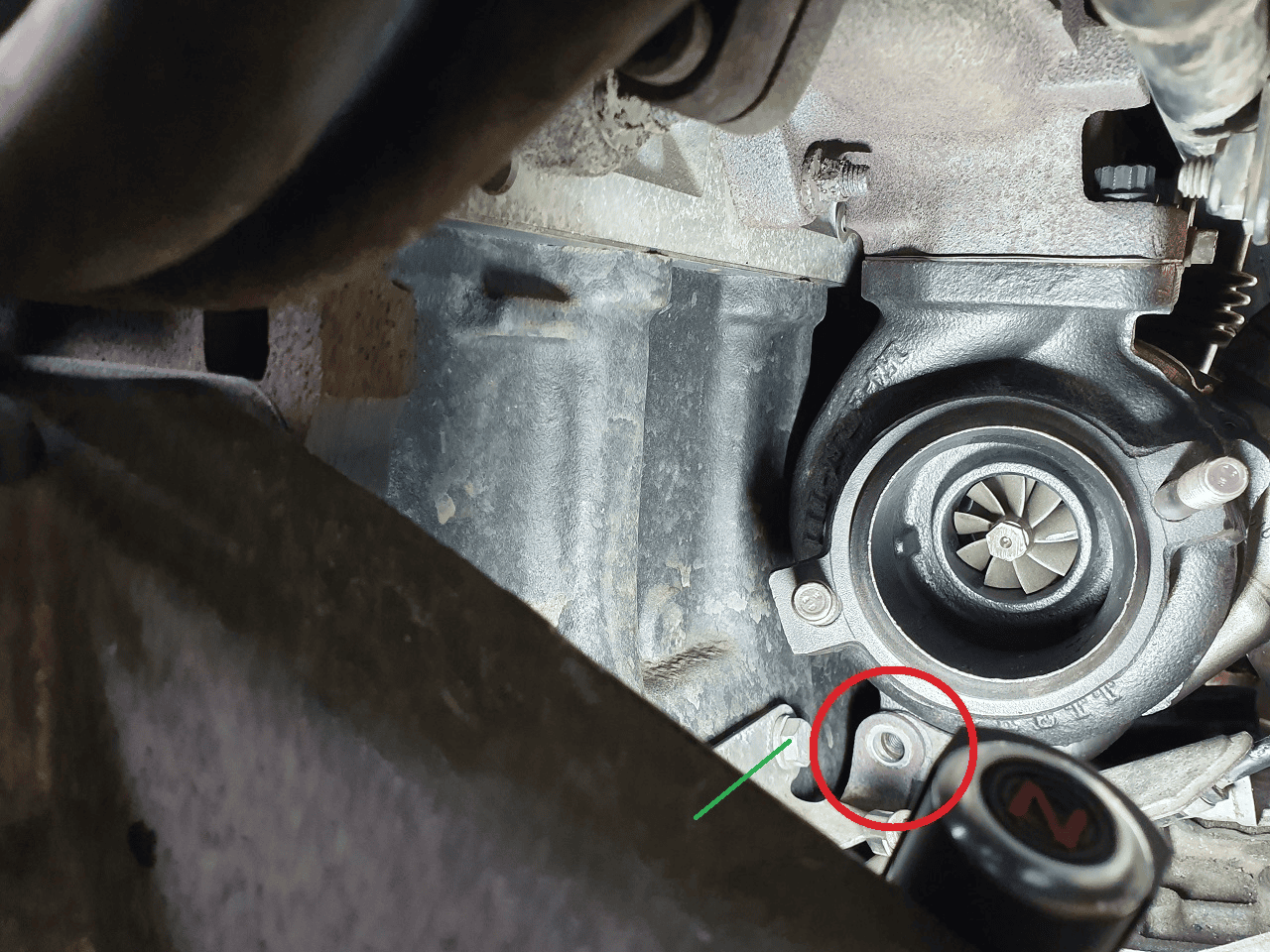

However since more persons had the same issue that I had, turbo moving but not getting out, the screw responsible for that is in the picture. In this case, is only the whole as it seems impossible to put it back for me at least.

I believe the guide should be updated, as it seems far better to refit if the other two screws are removed (green bar)

I also found it easier to remove the exhaust side screws without so many extensions, leaning over on the left side of the battery, plenty of room there for manoeuvre, perhaps only direct from wheel arch.

However since more persons had the same issue that I had, turbo moving but not getting out, the screw responsible for that is in the picture. In this case, is only the whole as it seems impossible to put it back for me at least.

I believe the guide should be updated, as it seems far better to refit if the other two screws are removed (green bar)

I also found it easier to remove the exhaust side screws without so many extensions, leaning over on the left side of the battery, plenty of room there for manoeuvre, perhaps only direct from wheel arch.

Also I don't think is possible to refit it as one person, unless I am not smart enough. The turbo needs to be lifted and directed with the gasket from below while somebody screws it from the top. Also, these screws are not steel so if you drop it, quite difficult to get out. I used a piece of a rubber glove to keep it in the socket. All this while again directing it into the oil return hose.

Great guide but I believe it should be extended to refitting it.

There should also be some corrections. Those 3x screws (originally) are not 10mm, these are 12 or 13mm (can't remember by head) with many "teeth", I am not sure how they are called, something like: https://www.ffx.co.uk/tools/product/Facom-Fcms13La-3148510553153-Deep-Socket-1-2-In-Drive-13Mm

Do not use a 12mm normal socket, it will round them up and if that happens, big trouble ahead. Search 11652243402 on google to see how they look.

Great guide but I believe it should be extended to refitting it.

There should also be some corrections. Those 3x screws (originally) are not 10mm, these are 12 or 13mm (can't remember by head) with many "teeth", I am not sure how they are called, something like: https://www.ffx.co.uk/tools/product/Facom-Fcms13La-3148510553153-Deep-Socket-1-2-In-Drive-13Mm

Do not use a 12mm normal socket, it will round them up and if that happens, big trouble ahead. Search 11652243402 on google to see how they look.

Last edited:

Jayridium

Well-Known Member

- Posts

- 1,418

- Location

- Pedronapper (Peterhead)

Also I don't think is possible to refit it as one person, unless I am not smart enough. The turbo needs to be lifted and directed with the gasket from below while somebody screws it from the top. Also, these screws are not steel so if you drop it, quite difficult to get out. I used a piece of a rubber glove to keep it in the socket. All this while again directing it into the oil return hose.

Great guide but I believe it should be extended to refitting it.

There should also be some corrections. Those 3x screws (originally) are not 10mm, these are 12 or 13mm (can't remember by head) with many "teeth", I am not sure how they are called, something like: https://www.ffx.co.uk/tools/product/Facom-Fcms13La-3148510553153-Deep-Socket-1-2-In-Drive-13Mm

Do not use a 12mm normal socket, it will round them up and if that happens, big trouble ahead. Search 11652243402 on google to see how they look.

I did mine myself with by removing the top engine mount and getting a scissor jack between the back ot the head and the bulkhead than jacking the engine away from the bulkhead. The socket for those bolts is just a twelve sided socket, often called a bi-hex or double-hex. I prefer using single hex sockets for most things, but doublehex sockets are so cheap its not worth owrrting about, indeed your cheaper and nastier socket sets tend to be uniformly doublehex...

Barnview104

Member

- Posts

- 58

- Location

- Kent.

hi

How exactly did you do that with the jack ?

makes perfect sense to me.

How exactly did you do that with the jack ?

makes perfect sense to me.

I did mine myself with by removing the top engine mount and getting a scissor jack between the back ot the head and the bulkhead than jacking the engine away from the bulkhead. The socket for those bolts is just a twelve sided socket, often called a bi-hex or double-hex. I prefer using single hex sockets for most things, but doublehex sockets are so cheap its not worth owrrting about, indeed your cheaper and nastier socket sets tend to be uniformly doublehex...

doogiescott

Member

- Posts

- 13

- Location

- Keith, Banffshire

Thanks for that. I'm going to give it a go following your instructions. Printed off and added to my Haynes manual.Can you change the turbo on a freelander TD4 without removing the IRD? well the simple answer is yes... i have just removed the turbo on my hippo and i will share.

Jack up and support vehicle with axle stands

1. remove engine cover

2. remover air filter cover

3. remove air filter

4. remove turbo hose from pressure side of turbo (outlet) two jubilee clips and from MAF (inlet) two clips and it slides right off.

5. remove the turbo control solenoid complete with bracket (this can be done from above)

6. remove oil banjo bolt

Now comes the tricky bit

7. from under the car remove the retaining bolt on the exhaust pipe

8. gaining access from the passenger side wheel arch where the steering rod goes through (using extensions) remove the other retaining bolt on the exhaust.

9. for easy access to mounting bolts and oil return hose cable tie exhaust out of the way.

10. with your arm up over the top of the IRD you can access the jubilee clips for the return hose (6mm ratchet does the trick)

11. just above the return hose there are two 13mm retaining bolts for the turbo (good pic of this in haynes manual) you have to go by feel but it's not too bad.

12. all that is now holding the turbo on are the three bolts that are accessed through the air filter housing.

13. remove three rubber bungs and push down heat protection plate and slide toward windscreen.

14. with this remove there are three 10mm bolts accessed through the holes.

15. OMG the turbo is off.

don't think I've missed anything

i actually did step 11 last..... i didn't know the bolts were there and was wondering why i couldn't get the bloody thing off. doing this last i was able to support the turbo from underneath and remove it that way.

I did this on my own (billy no mates) i have no previous landrover experience but i do know my way round a tool box and it took three/four hours. now i know where everything is i rec it could be done in 45mins to and hour with only the need to replace one gasket.

Similar threads

- Replies

- 0

- Views

- 636