At the risk of flogging a dead horse, I thought I'd write up the success I had at the weekend, along with a few more pictures for anyone else attempting this fix.

So, firstly, I checked the wiring where it enters the ECU box. The small harness on the front of the box is where I drilled the hole and fitted the reapir kit through the plastic.

I thought that maybe the small wires had either come loose or maybe the plug assemblys weren't fitted snugly, but all was well. If you want to take these out as I did to check the small wires then you need to remove the large plug on the right first with the brownish cables, then the next one, then the next one. The wires for this fix all fit into the third one you remove (this has 2 seperate blocks inside it - the three wires go 1 into one block and 2 into't'other).

That then leaves the harness itself and the sensor, so off with the air ducting for easier access (this is just a couple of screws and some jubilee clips. Keep your eye on the collar on one of the screws - it's necessary to tighten up the screw later on and will lead to much head scratching if you inadvertently let it slip off the screw and a right royal chore if you lose it). The picture below shows the green clip of the harness repair kit already taken off the sensor (you may need pliers to press in the clip beneath the plug for removal). You can trace the path of the new harness from the green plug to the ECU box on the right.

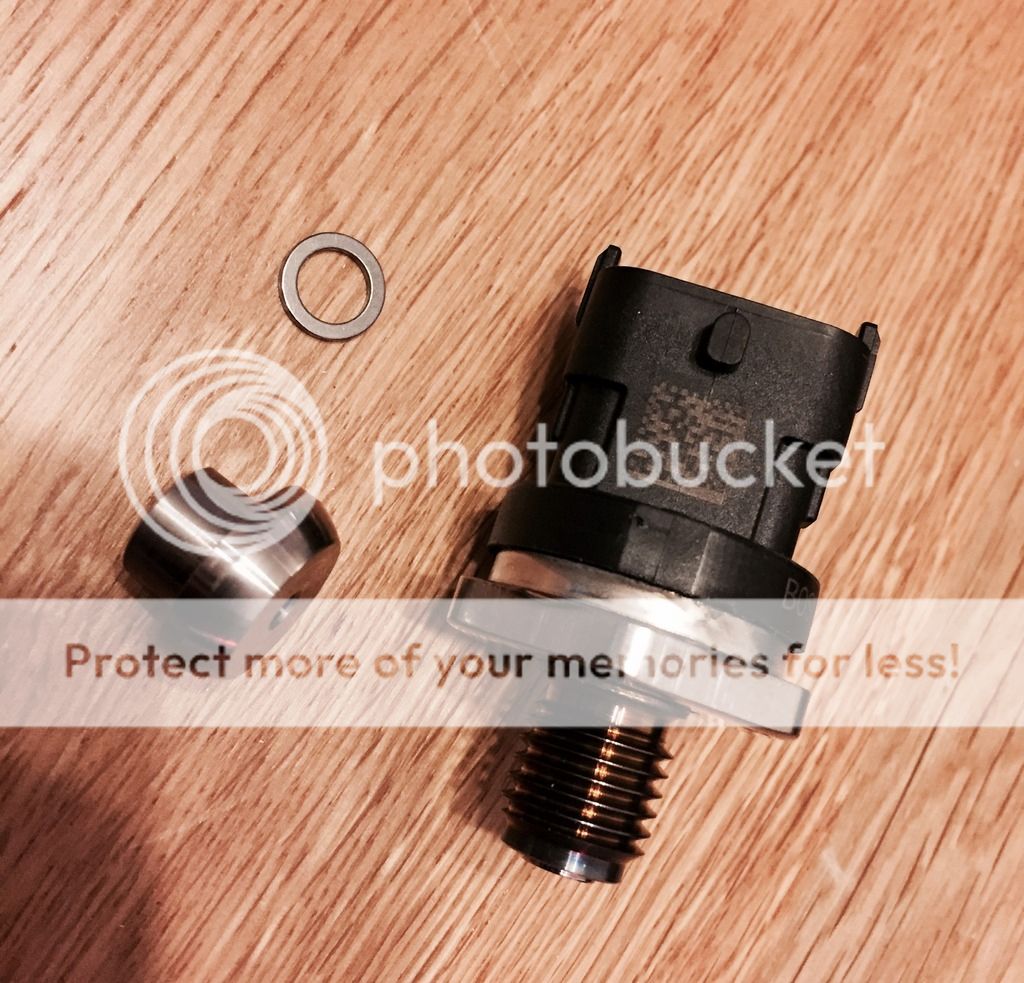

I was then in a position to take a look at the sensor itself, and especially at the contacts:

They didn't look too bad, and I have no reason to believe I need to replace the sensor as yet (maybe that will come if I continue to get the same problem). I cleaned up the sensor contacts with some xylene dabbed on a cotton bud and did similar with the plug contacts on the harness. I tried to get the sensor out in order to have a proper look at it but I didn't have the required socket (a deep 24mm or 26/27mm socket which must be big enough in the recess to surround the plastic shroud), so I decided to leave it there instead.

I then reconnected everything, gave it all a good clean to remove some of the oil residues hanging around on the plastics and gave it a go. Et, voi la - perfecto. Now it's driving great once again (although I said this following the harness mod fitting, and it's spannered up on me again).

One further thought - if you look at the green plug you will see that the wires are unprotected for the first 100mm or so, before being surrounded by a sheath for the rest of the route to the box. Are these wires susceptible in any way ? Would it help, do you think, if I were to wrap these in insulation tape to keep them in place and prevent any movement of the wires where they enter the plug assembly ? I'm tempted to get some heat shrink shrouding stuff and try that.

Still, currently it's working fine, so fingers crossed it will stay that way.

.... M