Land virgin

New Member

- Posts

- 3

- Location

- At the very top

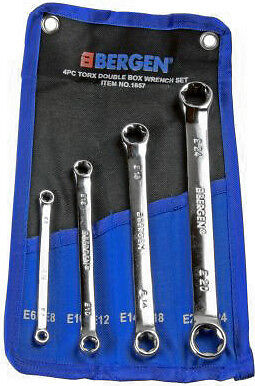

Hi, brand new to this but looking for some advice. I was changing the track rod end on my 55 plate freelander when I hit a problem trying to get it to wind off. Lots of swearing and some manic angle grinder strokes later I have damaged the thread on the track rod inner bar have ordered a new one but now I need to get the old one off. I see its held on by torx bolts but I am unable to fit the torx socket and ratchet into the gap. Is it possible to use an open ended spanner, 15mm seems to fit, and are the torx bolts left or right hand thread any advice will be gratefully received