700Quid

Active Member

- Posts

- 341

- Location

- The Iceni Badlands

Another gorgeous weekend of sunny weather meant alot of progress on Bumblebee. The Stallion popped round on Friday night and so ensued another weekend of to much beer, whiskey... absinth  and take-aways

and take-aways  whilst working on the Landy. Due to having an extra pair of hands I was able to get lots done. Both hubs, wheel bearing etc went back together first thing Saturday morning followed by the calipers. We then set about making up the new front brake pipes and having a right laugh trying to get a flange on the old steel pipe. The reason for this was so I didn't have to run new pipe all the way behind the engine. The rest was all replaced with copper. Eventually after several removals and refits we got the brakes bled and everything looking sweet. On to Sunday and started off making up the near side sill from my piece of box and repairing the near side pillar at its base. So a lot of fiddly plate work before welding it in to place. Cutting out the old sill was fine although in certain places it would have been really handy to have an Oxy Ace torch. Stallion suggested that at the end of the build I do a Top Ten of tools I personally couldn't have done without. I will also do a few of "tools that would have been dead handy to have" I think. So heres a couple of pics.. none of the sill yet as it was late when we finished and I couldn't be arsed..

whilst working on the Landy. Due to having an extra pair of hands I was able to get lots done. Both hubs, wheel bearing etc went back together first thing Saturday morning followed by the calipers. We then set about making up the new front brake pipes and having a right laugh trying to get a flange on the old steel pipe. The reason for this was so I didn't have to run new pipe all the way behind the engine. The rest was all replaced with copper. Eventually after several removals and refits we got the brakes bled and everything looking sweet. On to Sunday and started off making up the near side sill from my piece of box and repairing the near side pillar at its base. So a lot of fiddly plate work before welding it in to place. Cutting out the old sill was fine although in certain places it would have been really handy to have an Oxy Ace torch. Stallion suggested that at the end of the build I do a Top Ten of tools I personally couldn't have done without. I will also do a few of "tools that would have been dead handy to have" I think. So heres a couple of pics.. none of the sill yet as it was late when we finished and I couldn't be arsed..

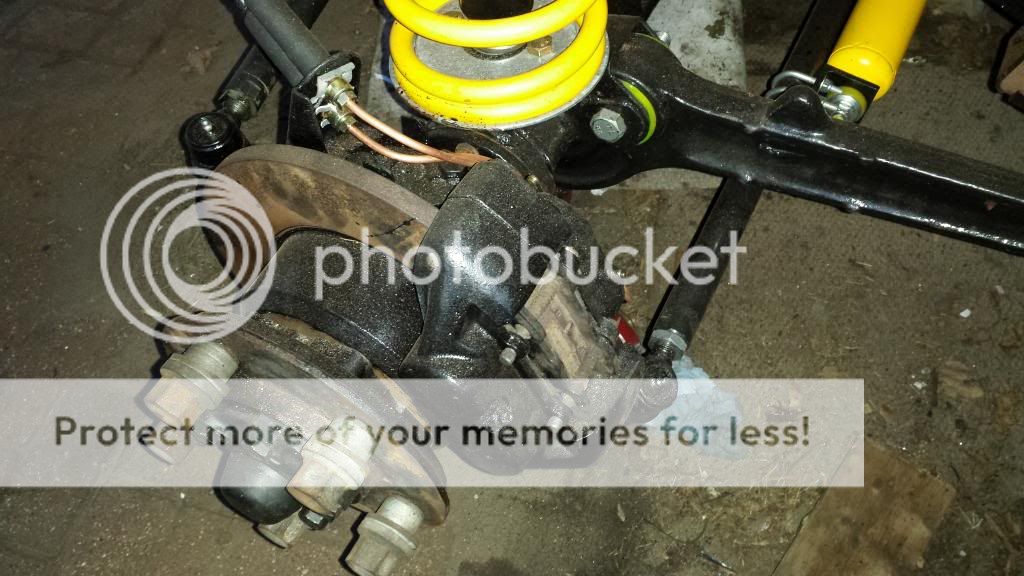

New pipes all in and looking good...

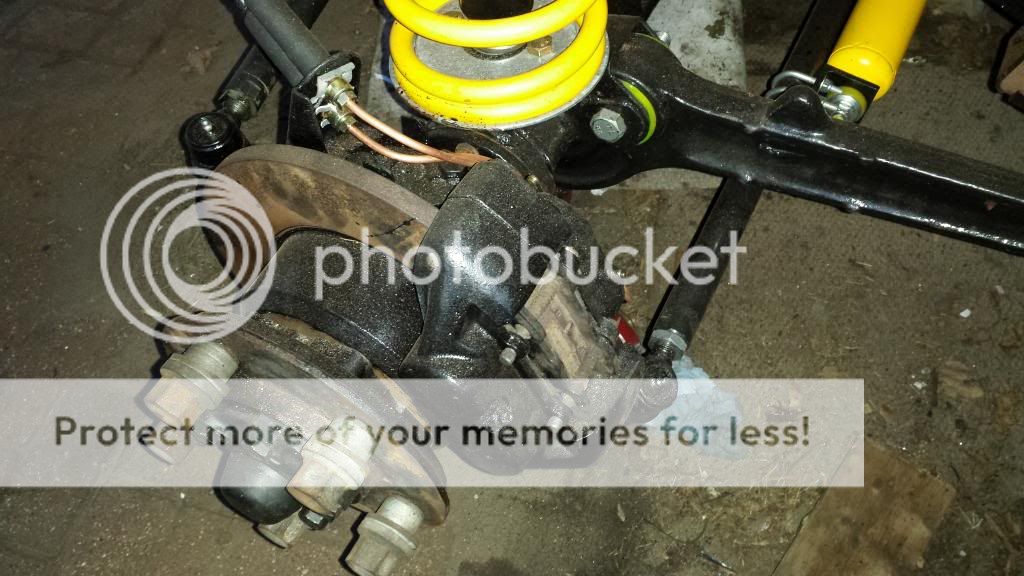

Hubs and calipers back on and ready to roll.

So I am finally nearing the end of the first part of my Landy journey. I still have a little bit of metal work to finish on the off side rear door but its not much. Then its seam sealer and shultz/waxoyl before filling and spraying. I will have a lot to "bits" to do here and there just to finish stuff off and continue improvements but it won't be long before she is back on the road.... hopefully...

New pipes all in and looking good...

Hubs and calipers back on and ready to roll.

So I am finally nearing the end of the first part of my Landy journey. I still have a little bit of metal work to finish on the off side rear door but its not much. Then its seam sealer and shultz/waxoyl before filling and spraying. I will have a lot to "bits" to do here and there just to finish stuff off and continue improvements but it won't be long before she is back on the road.... hopefully...

Last edited: