700Quid

Active Member

- Posts

- 341

- Location

- The Iceni Badlands

Hello one and all,

Before I start just let me say I have never, threaded, tweeted, squawked, poked, liked, posted, looked, nudged, elbowed, shouted, and any other computer jargony thing you can think of, before. This is my first time on a forum and like a lot of first times I may find the concept a little slippery and difficult to hold on to but I will try and hopefully it will be a happy ending :drum:...

Now I know there are a lot of rebuild threads (Right word???) but I thought I would share mine as well. Like a lot of other people I have drawn great inspiration from several of the other forum members and their builds. Notably Mr Noisy, Green Hornet and Robp... Although mine will be a slightly more boring build as I don't have the money for all the lofty high bits hopefully you can still draw some pleasure from watching all my mistakes.... and pointing fingers..... and laughing..... :hysterically_laughi

So the story so far :bored:

I brought my Landy just over a year ago it is a Disco 1 200 TDI. I went for the 200 Tdi because I like the fact its simple and everything is mechanical. I just wanted a toy for rolling round the woods in and throwing the dogs in, and it didn't matter if it got banged and scratched... When I brought the Landy it only had one months MOT left and my thought was bang it in see what happens after all it only cost me 700 quid. It passed only needing a bulb and front light reflector repair. SO instead of doing any work I have run it for the year and only now taken it off the road to fix it up. However in that year I have fallen completely in love with this motor. More so than my last one a Disco 1 V8, and although originally only planing basic work, I have decided to give her a proper job, as best I can. I have never welded before or done any major engine work. Hopefully by the end of this I will have done both

So here is how she looked when I brought her... pretty much... I fiddled with the bumper a bit....

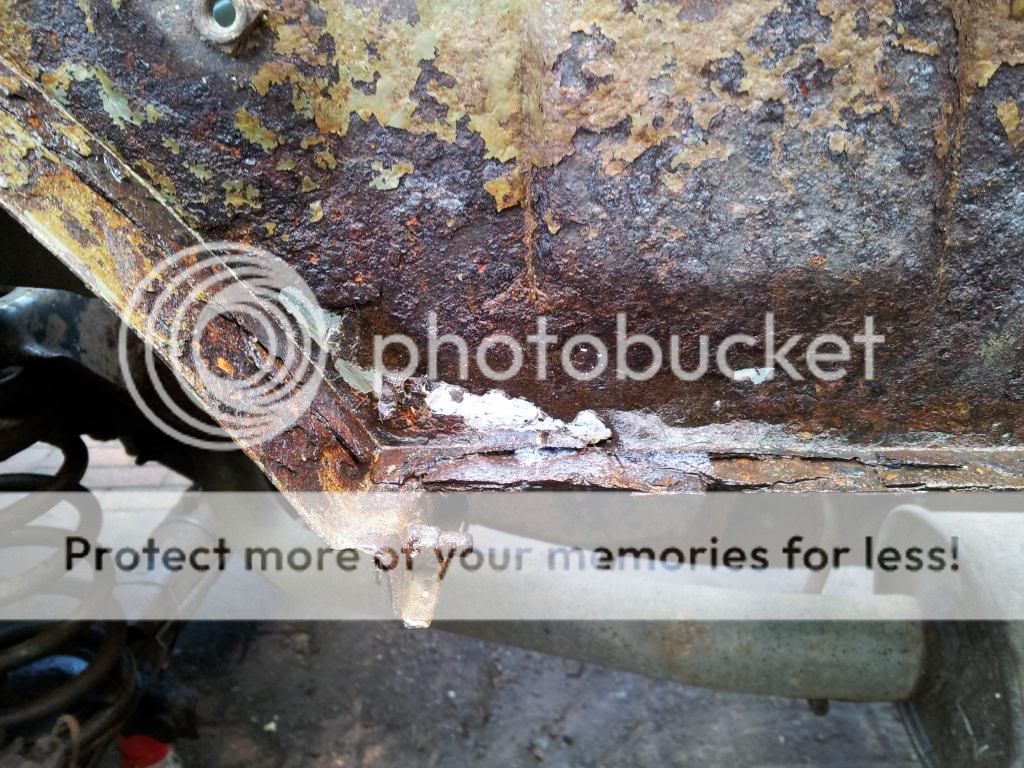

I hope these images come up ok??? The big change I am going to make to the look of the vehicle is the wheels. I like the black modular ones on paddocks website. I will run them with my current tires as they have a lot of tread on them 205 - 16 then change for either 225 - 75 - 16 or 245 - 70 - 16 price dependent. I am also planing to take a little bit off the rear quarter panel just to lift the rear end silhouette a little. I am fitting new springs and shocks, new brake pipes, new floor, chassis is being cleaned down then cold galvanized, primed and black enameled. I intend to over haul the brakes, remove the rear seats for more room, service the engine change the cam belt and probably do a million other things which I can't think of right now..... :crazy:

So if this works I will post again shortly with the photos of the work I did this weekend.....

Before I start just let me say I have never, threaded, tweeted, squawked, poked, liked, posted, looked, nudged, elbowed, shouted, and any other computer jargony thing you can think of, before. This is my first time on a forum and like a lot of first times I may find the concept a little slippery and difficult to hold on to but I will try and hopefully it will be a happy ending :drum:...

Now I know there are a lot of rebuild threads (Right word???) but I thought I would share mine as well. Like a lot of other people I have drawn great inspiration from several of the other forum members and their builds. Notably Mr Noisy, Green Hornet and Robp... Although mine will be a slightly more boring build as I don't have the money for all the lofty high bits hopefully you can still draw some pleasure from watching all my mistakes.... and pointing fingers..... and laughing..... :hysterically_laughi

So the story so far :bored:

I brought my Landy just over a year ago it is a Disco 1 200 TDI. I went for the 200 Tdi because I like the fact its simple and everything is mechanical. I just wanted a toy for rolling round the woods in and throwing the dogs in, and it didn't matter if it got banged and scratched... When I brought the Landy it only had one months MOT left and my thought was bang it in see what happens after all it only cost me 700 quid. It passed only needing a bulb and front light reflector repair. SO instead of doing any work I have run it for the year and only now taken it off the road to fix it up. However in that year I have fallen completely in love with this motor. More so than my last one a Disco 1 V8, and although originally only planing basic work, I have decided to give her a proper job, as best I can. I have never welded before or done any major engine work. Hopefully by the end of this I will have done both

So here is how she looked when I brought her... pretty much... I fiddled with the bumper a bit....

I hope these images come up ok??? The big change I am going to make to the look of the vehicle is the wheels. I like the black modular ones on paddocks website. I will run them with my current tires as they have a lot of tread on them 205 - 16 then change for either 225 - 75 - 16 or 245 - 70 - 16 price dependent. I am also planing to take a little bit off the rear quarter panel just to lift the rear end silhouette a little. I am fitting new springs and shocks, new brake pipes, new floor, chassis is being cleaned down then cold galvanized, primed and black enameled. I intend to over haul the brakes, remove the rear seats for more room, service the engine change the cam belt and probably do a million other things which I can't think of right now..... :crazy:

So if this works I will post again shortly with the photos of the work I did this weekend.....

Last edited:

.........the car.... :doh: Here are the photos of my progress so far

.........the car.... :doh: Here are the photos of my progress so far