had a couple of hours free today to play

not much but every little counts.

I traced the wiring from the roof lights down the side of the windscreen and under the scuttle trim, this took a while as that side of the car is in the hedge

i pulled some wireing through the firewall or front bulkhead or whatever people call it and finished wireing in the relay

i drilled some holes in a bracket under the glove box so i could bolt the relays to it

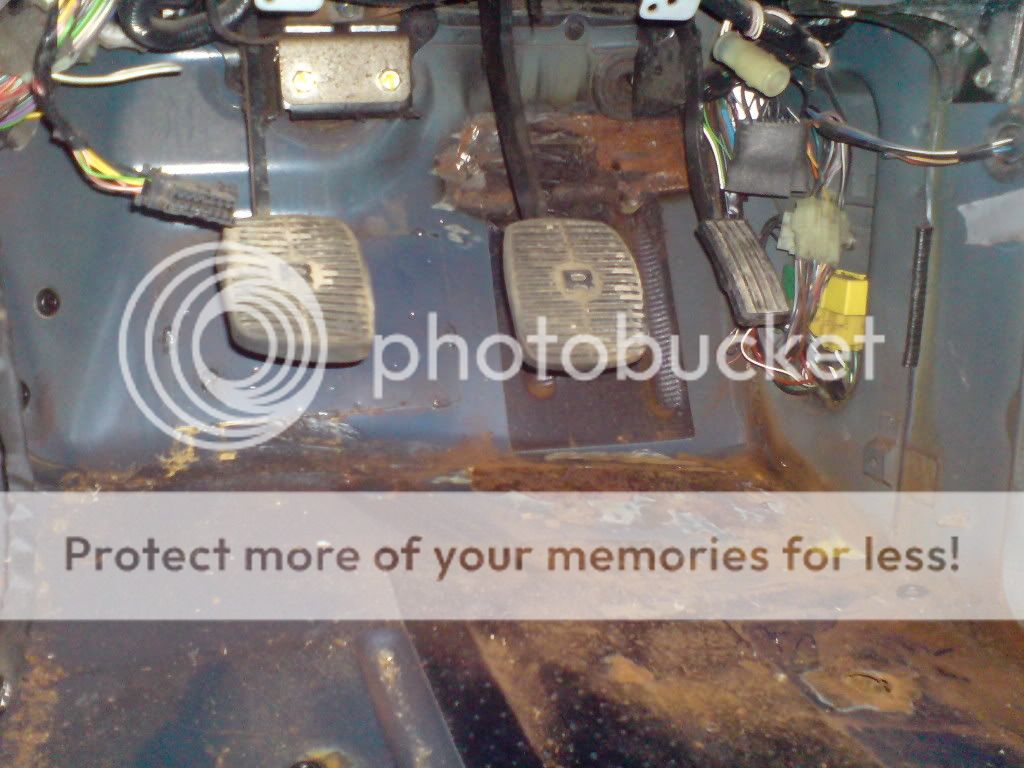

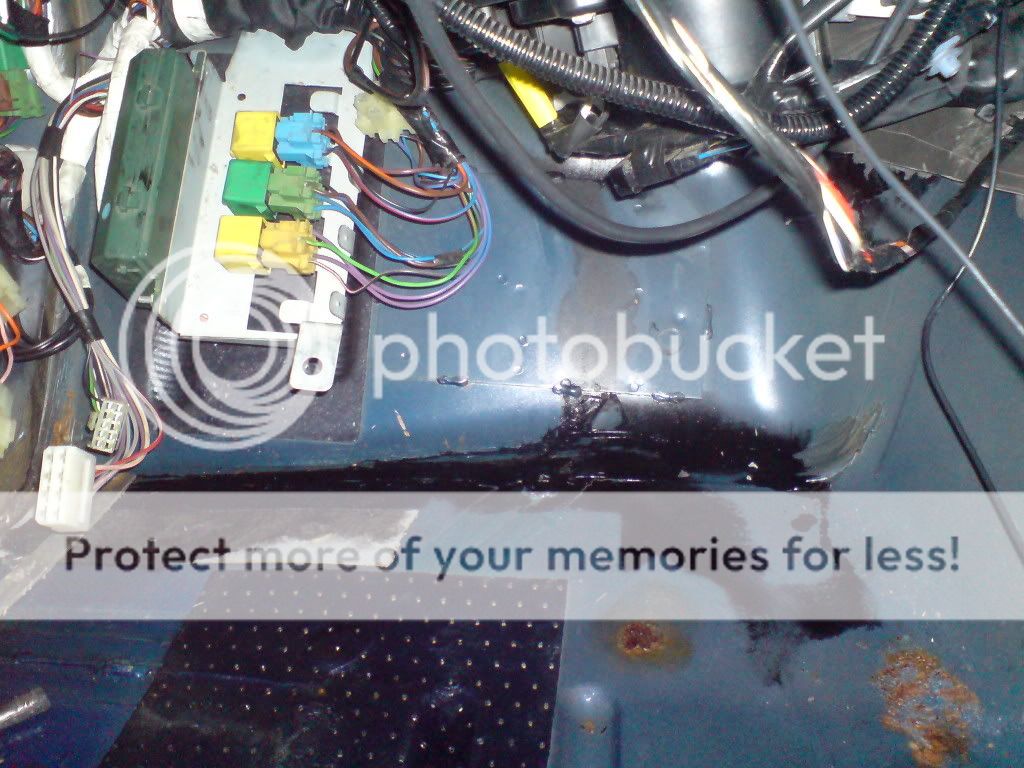

Cut the front sound proofing out so i could see what rust there is

Drivers side

Passengers side (feck knows where the oil came from)

then i sat and confused myself for a bit trying to convince myself that getting a double make and break relay would not solve my problems, am going to be wireing an electric fan in so i want to get all the wireing in so i can get the dash back together then put the fan in whenever i get around to it, but it's going to be going through an on - off - on switch

1st position will be normal as in the fan will activate when it hits the req temp, off will be for when/if i take the landy swimming or jet wash the rad that way it wont spray **** all over my engine and bay and the second on will be a constant feed to the fan just incase every think fooks up ;/ but have figured it out to be wired like this hopefully someone will spot any probs

PIN 1 - Power out 1 (through a relay to activate the electric thermostat)

PIN 2 - Power in (fused feed from ignition live poss starter or alternator)

PIN 3 - Power out 2 (Constant feed to the fan)

PIN 7 - Earth

PIN 8 - Sidelight feed in

Pin 3 will be wired through a relay to activate the fan

kenlowe say it's wired like this but i'm now confused again

don't suppose anyone knows what these rings are for?

i guessed one goes round the gear leaver but not sure why or what the other one is for